An assistant will be required to complete the work, as well as:

- viewing ditch or overpass;

- drill or piece of wire with a diameter of 2 mm;

- flat stretch of road, free from traffic.

Adjustment

1. We install an unloaded car on an inspection ditch or overpass («Preparing the car for maintenance and repair»).

2. Press the rear of the car several times to self-adjust the suspension.

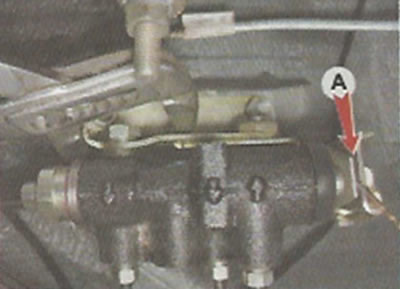

3. Using a piece of wire or a drill with a diameter of 2 mm as a probe, measure the gap «A» between plate and lever (see below photo p. 6), which should be 2.0-2.1 mm. If the gap does not correspond to the required size, we adjust the regulator drive.

4. Using a 13 mm spanner, loosen the bolt of the front fastening of the pressure regulator to the bracket.

5. With large sliding pliers, we shift the adjusting bracket, setting a gap between the plate and the lever of 2 mm.

6. We tighten the bolt of the front fastening of the pressure regulator to the bracket.

Examination

1. We leave by car on a flat section of the road, free from vehicles and other obstacles. The assistant steps aside and observes the blocking of the wheels of the car.

When braking hard, the rear wheels should lock up with a slight delay (1-2 s) regarding the locking of the front wheels.

2. At a speed of about 40 km / h, we sharply press the brake pedal with sufficient force to block the wheels.

- A) If the rear wheels are blocked before the front wheels, then the gap «A» need to be increased.

- b) If the rear wheels do not lock or lock too late, then the clearance «A» need to be reduced.