The most common starter failures are:

- 1. The winding burns out or the contact bolts and the contact plate in the traction relay burn out. To eliminate these faults, it is necessary to replace the traction relay. This can be done on the car without removing the starter.

- 2. Defective overrunning drive clutch. To eliminate this malfunction, it is necessary to disassemble the starter and replace the drive.

- 3. Worn starter brushes. Remove the starter, replace the brush assembly and clean the manifold. When replacing the brush assembly, there is no need to remove the starter drive and the traction relay.

To complete the work you will need:

- two power wires (with clips at the ends) to start the engine from the battery of another car;

- puller of external locking rings;

- ohmmeter.

Examination

Comment. You can check the electrical part of the starter without disassembling it.

1. Remove the starter (see «Starter - removal and installation»).

Warning! When checking, do not short circuit the wire clamp connected to the positive terminal of the battery to the starter housing. To do this, the clamp should be extended, for example, by inserting a steel punch into it.

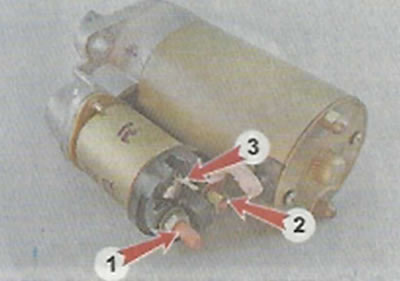

2. With one wire, connect the negative terminal of the battery to the starter housing. The second wire, connected to the positive terminal of the battery, is connected to the contact bolt 2 of the traction relay, to which the starter wire is connected. If the starter armature begins to rotate, the starter motor is good.

3. We connect the second wire to the contact bolt 1 of the traction relay. Using a screwdriver or other suitable metal object, we close the output 3 and the contact bolt 1 of the traction relay. If there was a loud click and the starter armature began to rotate, then the traction relay is working properly.

To further check the starter, as well as to determine the cause of the malfunction, it is necessary to disassemble the starter.

Disassembly

1. Using a 10 mm socket wrench, unscrew the nut that secures the wire tip to the terminal (contact bolt) traction relay.

2. Remove the wire tip from the contact bolt of the traction relay.

3. Using an 8 mm socket wrench, unscrew the two bolts securing the traction relay.

Comment. Depending on the starter model installed on the engine, the traction relay may be held in place by screws.

4. Remove the traction relay from the starter (in this case, it is necessary to disconnect the earring of the relay core from the upper end of the drive lever).

Recommendation. Check the ease of movement of the core of the traction relay. Connect an ohmmeter to the terminals of the traction relay and, sinking the armature to the stop, make sure that the contact bolts close (electrical resistance close to zero). A defective traction relay must be replaced.

5. Using a 10 mm socket wrench, unscrew the two nuts of the tie rods.

6. Having carefully disconnected the stator from the front cover, remove the stator from the studs.

7. Remove the central gear of the planetary gearbox (sometimes the gear remains on the armature shaft).

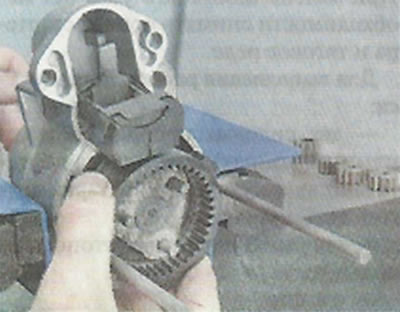

8. Using a slotted screwdriver, remove the three planetary gears of the gearbox one by one.

Recommendation. Check the condition of the planetary gear. The needle bearings of the satellite gears must not be damaged. The teeth of the gears of the reducer should not have chips, scuffs, traces of corrosion and other damage. It is necessary to replace the defective elements of the gearbox (either drive or starter assembly).

9. Resting against the top of the starter front cover with a screwdriver, pry off the drive lever support.

10. We remove the drive from the cover together with the drive shaft, the drive lever, the lever support and the external gear of the gearbox.

Recommendation. Check drive condition. The drive must move freely, without jamming, along the splines of the shaft. The drive gear must turn freely in only one direction, chipping of the teeth and strong nicks on the lead-in part of the teeth are unacceptable. Minor defects can be eliminated with a diamond file or an abrasive stone. It is necessary to replace a faulty and badly worn drive (or starter assembly).

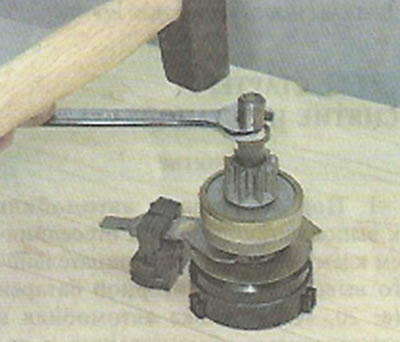

11. With a hammer, through a 13 mm open-end wrench, knock down the ring of the starter drive stroke limiter (at the same time, a wooden block or a piece of dense rubber should be placed under the gear of the gearbox).

12. With a slotted screwdriver, remove the stop ring of the drive travel stop from the groove of the shaft and remove the stop ring and travel stop ring from the shaft.

13. Remove the drive assembly with the lever and the clutch from the shaft.

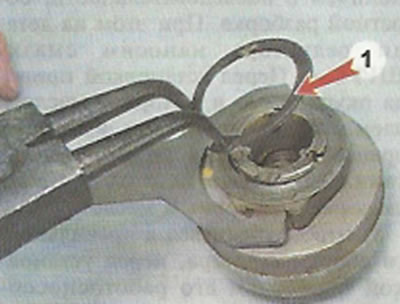

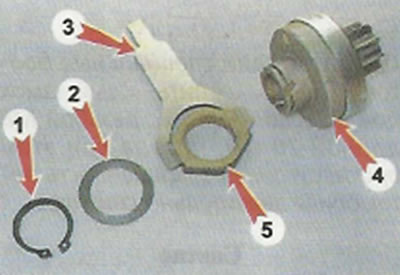

14. With a puller, remove the retaining ring 1 of the drive lever coupling.

15. Remove washer 2 from drive 4, clutch 5 assembled with drive lever 3.

Comment. When replacing only the drive, further work on disassembling the starter can be omitted.

16. With a puller, remove the retaining ring of the drive shaft support.

17. From the drive shaft 1, we sequentially remove the thrust washer 5, the shaft support 4, the sealing rubber ring 3 and the outer gear of the planetary gearbox 2.

18. Using a Phillips screwdriver, unscrew the two screws securing the brush assembly to the rear cover of the starter.

19. Remove the back cover.

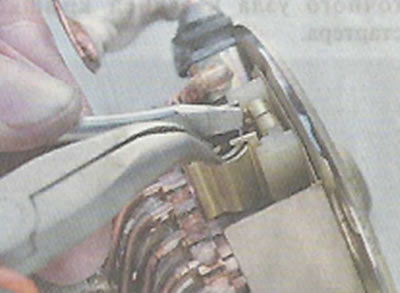

20. Prying with a slotted screwdriver, remove the brush assembly from the armature collector.

21. Remove the front armature shaft support.

22. Remove the thrust washer from the armature shaft.

23. Overcoming the force of the magnets, we remove the anchor from the stator.

24. We inspect the collector and armature windings.

Comment. Traces of charring of the windings are not allowed - such an anchor must be replaced.

25. We clean the contaminated collector with fine-grained sandpaper, holding the armature shaft through a strip of thick paper into the electric drill chuck. We wash the anchor with water and detergent to remove dirt, coal dust and abrasive residues and carefully wipe it dry with a clean rag, blow it with compressed air from a tire pump.

26. Replace worn brushes (the height from the working edge to the output is equal to or less than 3.5 mm) and brushes with mechanical damage.

27. We wash the parts of the gearbox and drive with white spirit or kerosene.

Assembly

You can install the brush assembly on the starter armature collector using a special mandrel or using a tool head of a suitable size and shape. If they are not available, brushes can be installed without these devices. For this:

- 1) with two screws we fasten the brush assembly to the rear cover of the starter;

- 2) lubricate the end of the armature shaft with two drops of engine oil;

- 3) insert four brushes into the corresponding brush holders. Without inserting the brush springs into the brush holders, we put the brush assembly on the armature collector;

- 4) with pliers with thin sponges, we bend the outer stops of the springs of all four brushes;

- 5) insert a spring into the brush holder;

- 6) holding the spring with a screwdriver, bend the four stops of the spring with pliers. Install the other three springs in the same way;

- 7) we insert the starter anchor into the stator with the brush assembly and rear cover put on it (at the same time, it is necessary to hold the anchor so that its collector does not disengage from the brush assembly). Further assembly of the starter is carried out in the reverse order of disassembly. At the same time, we apply SHRUS-4 grease to the parts of the gearbox. Before installing the drive, dip it in engine oil and let the oil bake. The bushings in which the armature and drive shafts rotate, as well as the screw splines of the drive, are lubricated with engine oil;

- 8) to make sure that the starter is assembled correctly, before installation, we check its performance, as shown at the beginning of the section.

|  |