To do the job, you will need a wrench to tension the timing belt.

Execution sequence

1. We prepare the car for work («Preparing the car for maintenance and repair»).

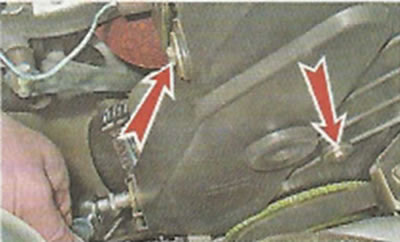

2. With a 10 mm wrench, unscrew the three bolts securing the front cover of the timing belt.

3. Raise the cover vertically upwards, and then remove it from the engine.

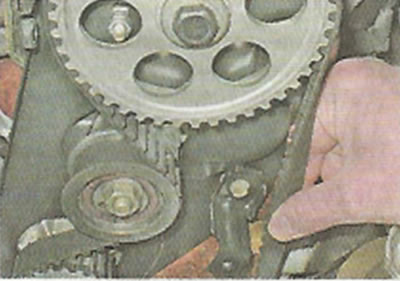

4. Rotating the crankshaft, visually check the condition of the belt.

Comment. The crankshaft can be rotated with a 17 mm ring wrench for its pulley bolt or with a large slotted screwdriver for the flywheel teeth. To do this, remove the rubber plug from the hole in the clutch housing.

The belt must be clean, free of dirt and oil on its surface. A belt with tears, cracks, delaminations, sheared or worn teeth, scuffs to the cord must be replaced (see below).

5. With two fingers, we try to turn the belt 90°in the area between the pulleys of the crankshaft and camshafts, applying a force of 15-20 Nm to it (1.5-2.0 kgf·m).

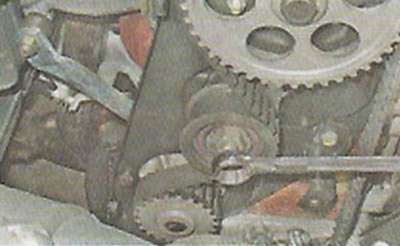

If the applied force is not enough to turn the belt to the required angle, the belt will be overstretched; if rsgmen can be rotated to a larger angle. It means the belt is not tight enough.

Warning! Excessive belt tension, oil and dirt on the belt will shorten the life of the belt, as well as accelerate the wear of the tensioner and coolant pump bearing.

Belt tension should be adjusted on a cold engine.

6. With a 17 mm wrench, loosen the tightening nut of the tension roller.

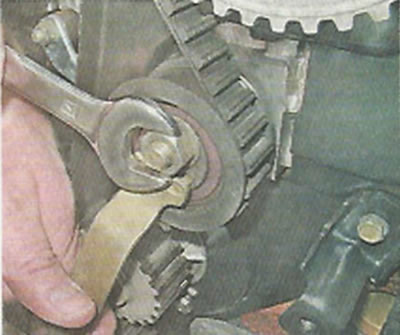

7. Turning the roller with a special key, we achieve the required belt tension and, holding the roller in this position, tighten the nut of its fastening.

8. Check the belt tension (see above) and repeat the adjustment if necessary.

9. Finally tighten the roller fastening nut to a torque of 33.23-41.16 N·m (3.4-4.2 kgf·m).

10. Replace the front cover of the belt and tighten the bolts of its fastening.