You will need a multimeter to do the job (in voltmeter mode).

Removing

1. We prepare the car for work («Preparing the car for maintenance and repair»).

2. Having released the latch, disconnect the block of wires from the crankshaft position sensor.

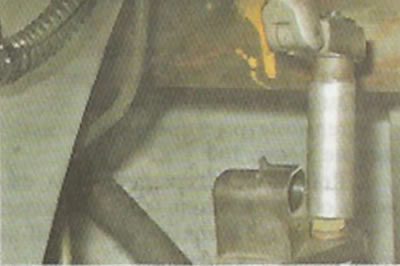

3. Using a 10 mm socket wrench, unscrew the bolt securing the crankshaft position sensor.

4. Remove the sensor.

Examination

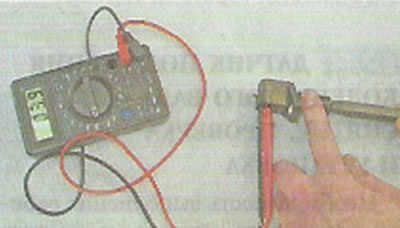

1. Connect a multimeter to the sensor terminals (in voltmeter mode with a measurement limit of up to 200 mV).

2. We quickly carry the screwdriver blade near the end of the sensor, while observing voltage surges on the voltmeter.

Comment. More accurately, the sensor can be checked by taking readings from it when it is installed on the engine and the crankshaft pulley rotates. For a serviceable sensor, the voltage at the terminals reaches 0.3 V. We replace the faulty sensor.

Installation

Install the crankshaft position sensor in the reverse order of removal. With a set of feelers, we check the gap between the end face of the sensor and the teeth of the crankshaft pulley. The gap should be 1±0.41 mm, it is set by the design of the sensor and is not adjustable.

Advice. If the gap is more than normal, remove the dirt from under the sensor.