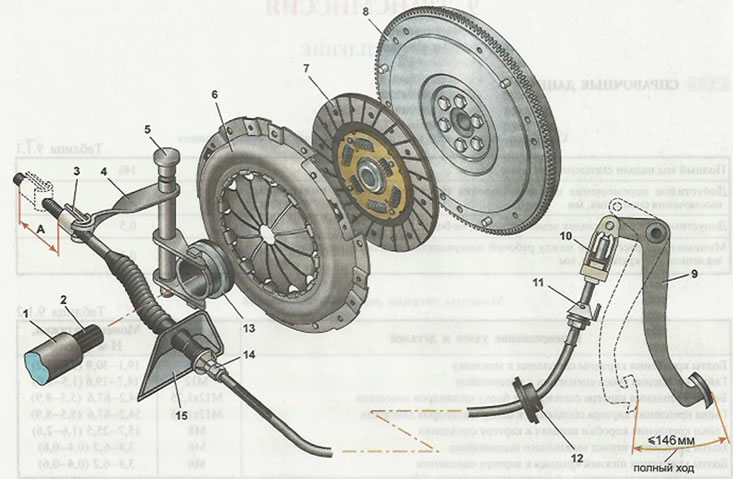

Clutch: 1 - release bearing guide sleeve; 2 input shaft of the gearbox; 3 - cable leash; 4 - clutch release fork; 5 - fork axle bushing; 6 pressure plate assembly (basket); 7 - driven disk; 8 - flywheel; 9 - clutch pedal; 10 - mechanism for automatic adjustment of the cable length; 11 - bracket; 12 - cover; 13 - clutch release clutch (release bearing); 15 - bracket mounted on the gearbox housing; 14 - lower tip of the cable sheath; A - mixing distance of the leash, checked when installing the cable (27 mm).

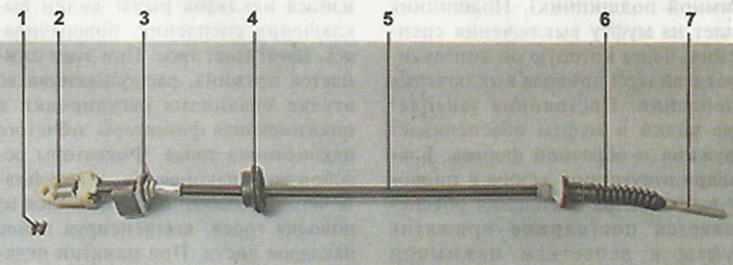

Clutch release cable: 1 - spring fixing bracket; 2 - mechanism for automatic adjustment of the cable length; 3 - cable sheath bracket: 4 - rubber cover; 5 cable sheath; 6 - corrugated cover of the lower end of the cable; 7 - threaded (lower) cable tip.

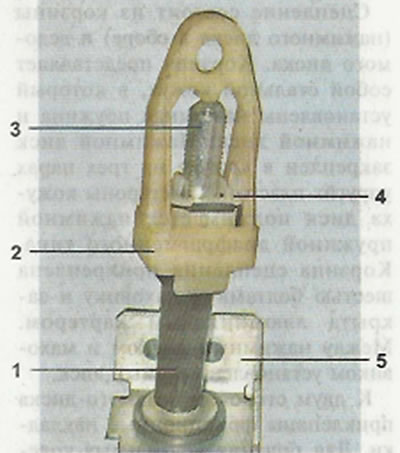

Cable length adjustment mechanism: 1 - bushing; 2 - leash; 3 - gear (upper) cable end; 4 - cable end clamps: 5 - bracket (with clutch pedal travel limiter)

The car is equipped with a single-disk dry-type clutch with a central pressure spring. The clutch release drive is cable-operated, backlash-free, with a mechanism for automatically adjusting the length of the cable.

The clutch consists of a basket (pressure plate assembly) and slave disk. The basket is a steel casing in which the pressure spring and the pressure plate are installed. The pressure plate is fixed in the casing on three pairs of elastic plates. From the side of the casing, the disk is pressed by a pressure spring of the diaphragm type. The clutch basket is attached with six bolts to the flywheel and is covered with an aluminum crankcase. A driven disk is installed between the pressure plate and the flywheel.

Friction linings are riveted to two sides of the driven disk. To dampen torsional vibrations at the moment the clutch is engaged, a damper with six coil springs is integrated into the driven disk. The hub of the driven disk enters splined engagement with the input shaft of the gearbox.

The clutch pedal is suspended on the axle and is attached to the body through the bracket. The clutch pedal sensor is mounted on the bracket. The signal from the sensor is sent to the ECU of the engine management system. The upper part of the clutch pedal is made as a two-arm lever. At the end of the lever there is a pin to which the clutch release cable is connected. The connection is made through a special ratchet mechanism that regulates the length of the cable (see below). Therefore, during the operation of the car, it is not necessary to regularly check and adjust the travel of the clutch pedal. This mechanism also ensures that there is no play in the clutch release actuator.

The cable is laid in a metal sheath with a polyethylene coating. The upper end of the shell has a bracket that is attached to the pedal assembly. The vertical surface of the bracket also serves as a travel limiter for the clutch pedal. It has a rubber plate on it. The lower end of the cable sheath is fixed in a bracket mounted on the gearbox housing. The lower end of the rope is closed with a rubber corrugated cover. The cable is connected to the clutch release fork lever through a plastic leash screwed onto the threaded end of the cable.

The clutch release fork rotates in two bushings. The upper sleeve is plastic, removable, and the lower one is bronze, pressed into the clutch housing. When the fork is turned, the force is transferred to the pressure spring petals through an angular contact ball bearing (release bearing). The bearing is put on the clutch release clutch, through which it contacts the clutch release fork. The constant engagement of the fork and the clutch is provided by a U-shaped spring. Due to the lack of play in the clutch release drive, the clutch is constantly pressed against the pressure spring petals, while the release bearing is continuously working. The bearing is lubricated for its entire service life. The clutch release clutch will move along the guide sleeve, put on the primary gearbox and attached to the clutch housing with three bolts.

During operation, the lining of the driven disk wears out. To compensate for this wear, an automatic cable length adjustment mechanism is built into the clutch release actuator. As the pads wear, the clutch release fork lever, turning, pulls the cable. In this case, the spring is compressed, located in the bushing of the adjustment mechanism and pressing the clamps of the toothed tip of the cable. The retainers release the tip, as a result of which it is freely pulled out of the cable leader, compensating for wear on the disc linings. When you press the clutch pedal, the upper drag will move up. At the same time, the clamps compress the toothed tip of the cable, preventing it from moving out of the body of the adjustment mechanism.