1. Remove the starter from the car (see «Removal and installation of a starter»).

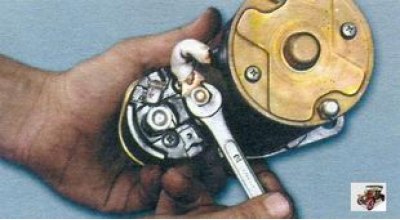

2. Turn away a nut of fastening of the tire to a contact bolt of a starter.

3. Disconnect the tire from a contact bolt of the traction relay of a starter.

4. Turn away two bolts of fastening of the traction relay of a starter and remove the relay.

5. Remove the anchor of the traction relay by lifting it up so that the anchor loop is removed from the lever.

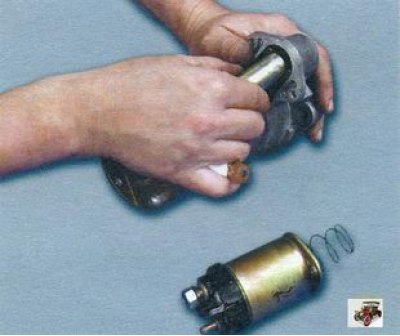

6. Remove the two tie rod nuts.

7. Remove drive side starter cover with gear and drive assembly.

8. Remove the starter cover from the collector side with the brush holder and brushes.

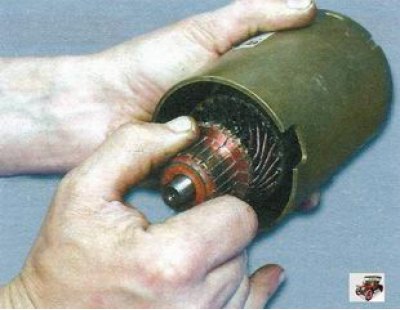

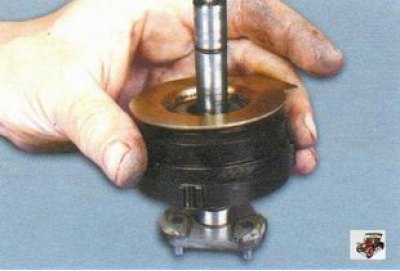

9. Remove the starter gear from the armature shaft.

10. Remove the armature from the stator.

11. Pay attention to the fact that a washer is installed on the starter armature shaft on the drive side.

12. Remove the starter armature shaft support.

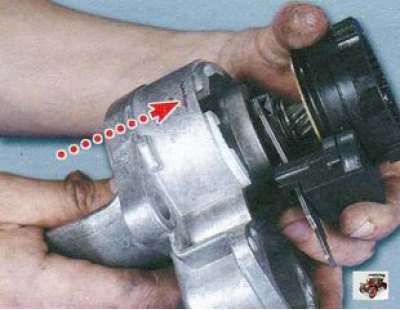

13. Turn out from a cover of a starter from outside a drive two coupling hairpins. It is not necessary to unscrew these studs, but it is more convenient to remove the gearbox and drive without them.

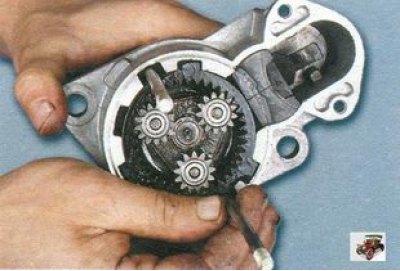

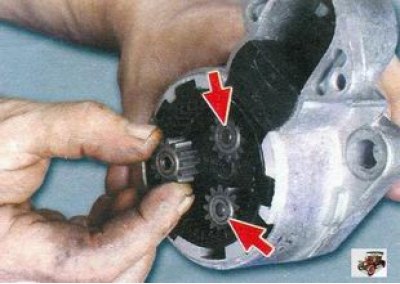

14. Take out three planetary gear wheels of a reducer. If their teeth or needle bearings embedded in the gears are damaged, replace the gears.

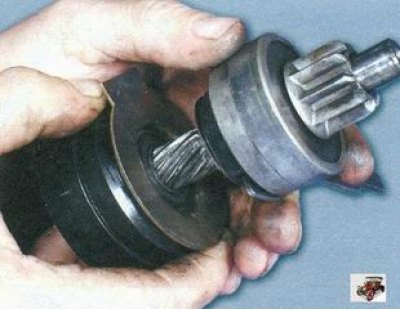

15. Remove the gearbox with the drive from the cover by pressing the starter drive gear.

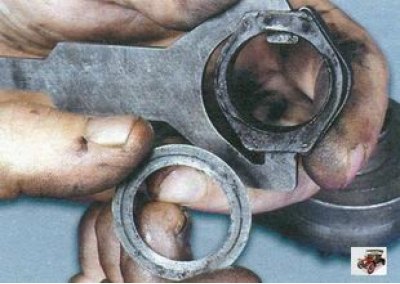

16. Remove the support with the seal from the lever.

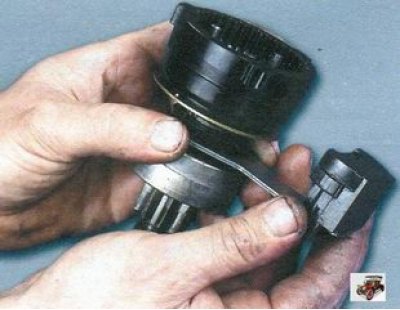

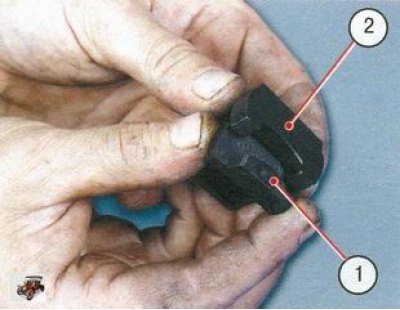

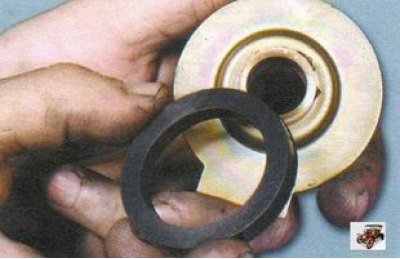

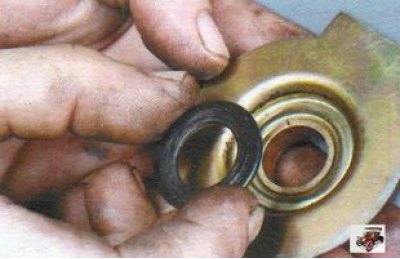

17. Remove the support 1 from the seal 2. The plastic support must not be badly worn or damaged. Replace a defective support, as well as a badly deformed or hardened rubber seal.

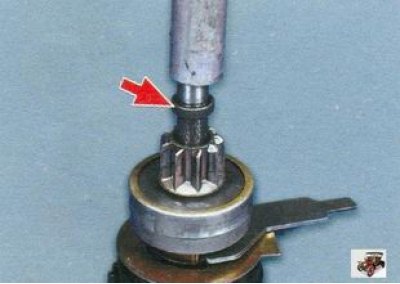

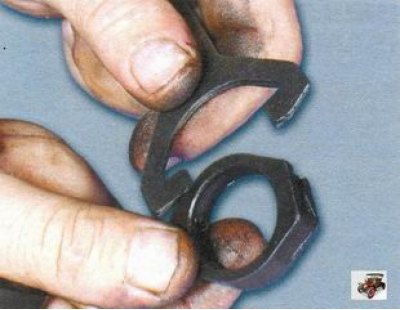

18. Knock the stop ring off the stop ring using a suitable drift.

19. Remove the retaining ring, and then restrictive.

20. Remove the drive assembly from the drive shaft.

21. Remove a lock ring of the lever.

22. Remove lever with driver and washer.

23. Remove the lever spring.

24. Remove the lever from the leash and separate the halves of the lever.

25. Remove the internal gear circlip.

26. Remove the internal gear and drive shaft support from the shaft.

27. Remove the o-ring from the support. Replace a badly deformed or loose ring.

28. Remove the insert from the support.

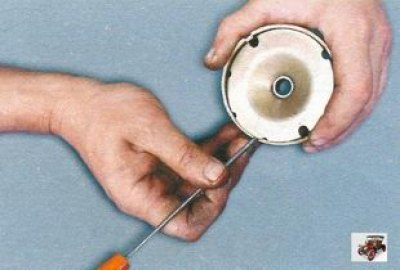

29. Remove the two screws and remove the brush holder from the cover on the collector side.

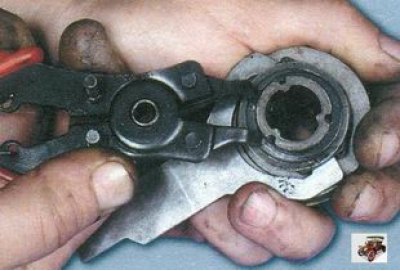

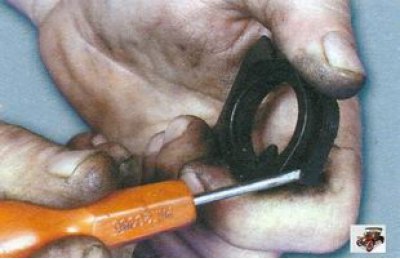

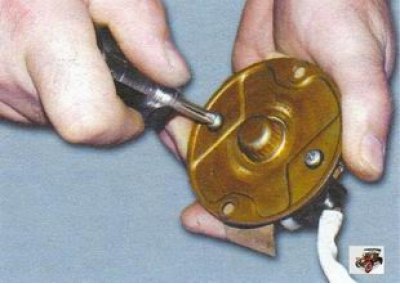

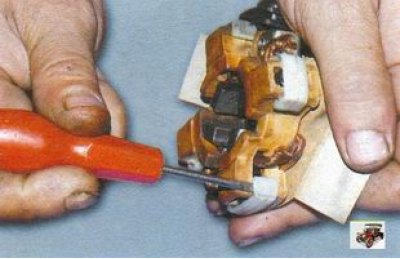

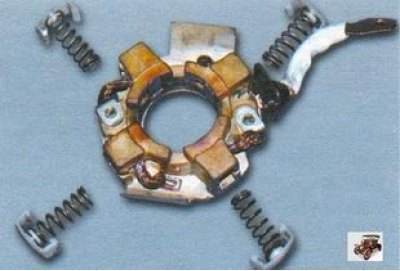

30. Prying off the brush holders with a screwdriver...

31.... remove them and clamping springs. Replace deformed or damaged retainers and heavily compressed or bent springs.

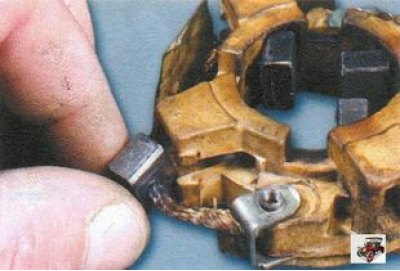

32. Remove the starter brushes from the brush holder guides.

33. Remove bare brushes.

34. Remove the cardboard insulating pad. Replace a torn or over-compressed gasket.

35. Remove the connecting bus with insulated brushes.

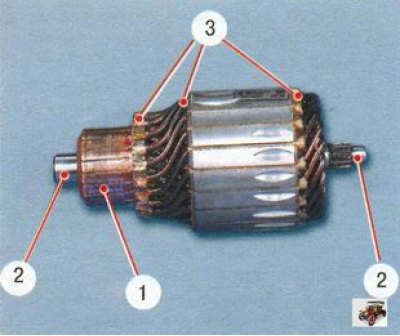

36. Inspect the starter anchor. If collector 1 is dirty or has marks, signs of burning, etc., sand the collector with fine glass sandpaper. If a yellow coating from the bearing is found on the shaft 2 of the starter armature, remove it with a fine sandpaper, as this can lead to jamming of the gear on the shaft. Check the reliability of the soldering of the winding leads of the 3rd armature to the collector plates. Inspect the starter winding at the ends of the armature, the diameter of the winding should be less than the armature iron package. Otherwise, replace the starter anchor.

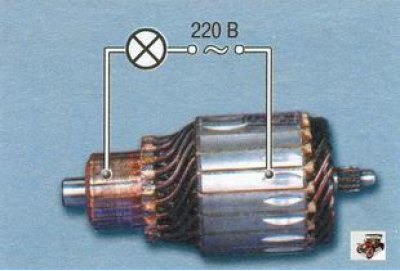

37. Check up a condition of a winding of an armature of a starter by means of the control lamp fed with alternating current with a voltage of 220 V. Supply voltage to a collector plate and a core of a starter armature. The lamp should not light up. If the lamp is on, then there is a short circuit in the starter armature winding or collector plate on «mass». In this case, replace the starter anchor.

38. While holding the freewheel, turn the starter gear in both directions: clockwise, the starter gear should rotate freely, and counterclockwise should not rotate. Otherwise, replace the starter drive.

39. Install the starter drive on the drive shaft, it should move freely, without jamming, along the splines of the shaft.

40. If the starter drive parts are badly worn or damaged, replace the starter drive. If nicks are found on the engagement part of the gear teeth, grind them with a fine-grained emery wheel of small diameter.

41. Inspect the bushings that rotate the shafts installed in the drive side starter cover, manifold side cover, armature shaft support, and starter drive shaft support. If the bushings are worn or have scuffs, pits, or other defects, replace the starter covers or bearings with defective bushings. Also replace starter covers and cracked mounts.

42. Inspect the starter stator; if it shows signs of grabbing the anchor, replace the starter rear cover and intermediate support.

43. Starter brushes worn to a size between the working surface and the output of less than 3.5 mm, replace.

44. Check the ease of movement of the starter brushes in the guides of the brush holder. They should move without jamming, and the brush holder itself should not have chips or cracks.

45. Inspect the starter drive shaft. Screw slots and necks should not have scoring and heavy wear. Remove traces of copper transfer from the bushings on the necks with a fine glass sandpaper, since subsequently they can cause the shaft to jam. The carrier and its three gear axes must not have play in the joints.

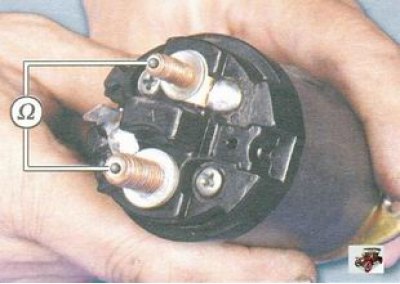

46. Check up an ohmmeter, whether contact bolts of the traction relay of a starter are closed by a contact plate. To check, assemble the circuit shown in the photo and slide the starter armature inside the traction relay until it stops. If the bolts do not close, replace or repair the starter traction relay.

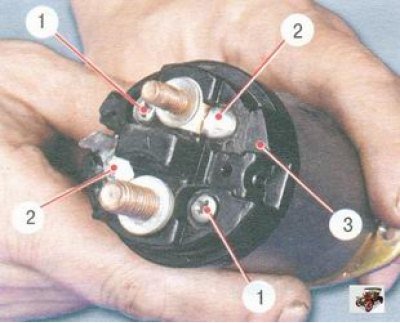

47. To repair the starter traction relay, unscrew the two screws 1 and solder the conclusions 2 of the traction relay windings, remove the cover 3, clean the bolt heads and the contact plate with sandpaper. If the bolt heads are badly burnt, turn the bolts 180°. Assemble the starter relay in reverse order

48. Reassemble the starter in reverse order. Before assembling the starter, lubricate the drive gear teeth with engine oil, the drive shaft helical splines, the internal gear teeth, the planetary gears, and the rotor shaft splines with grease (CIATIM-201, 202, 203 or Litol-24).

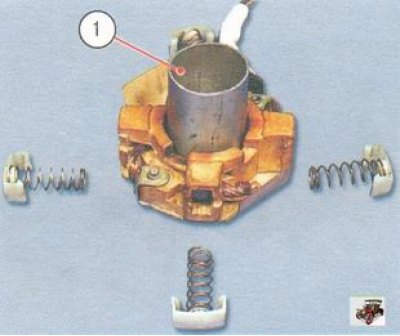

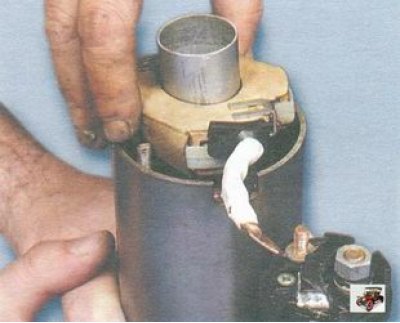

49. The brush holder must be installed in the starter separately from the cover on the collector side, since the starter brushes are pushed out of the guides by springs and it is impossible to keep them in their original position without a special device. For pre-assembly and installation of the brush holder, use a thin-walled mounting sleeve 1 with a diameter equal to the diameter of the collector or slightly larger than it (about 30 mm).

50. Install the assembled brush holder into the starter housing until it stops, remove the mounting sleeve and install the cover on the collector side.