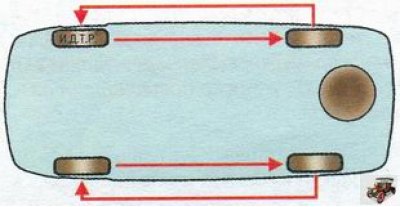

Pic. 2.1. The scheme of rearrangement of wheels on a car

Attention! Carry out all wheel repair work in specialized car repair shops.

1. Unscrew the cap from the valve.

2. Check tire pressure. To do this, connect a pressure gauge to the valve and press it. 3. If the air pressure in the tire is less than required, connect the hose tip to the valve and pump air, controlling the pressure on the pressure gauge on the pump.

4. If the air pressure in the tire is more than required, press the special protrusion of the pressure gauge on the spool and let the air out of the tire. Measure the pressure with a manometer. By repeating these works, bring the air pressure in the tires to normal.

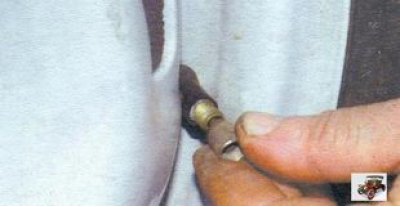

5. If you notice that the air pressure in the tires is constantly dropping, try tightening the spool with a cap with a wrench.

6. In order to check the tightness of the spool, wet the threaded hole of the valve. If air bubbles appear, replace the spool.

7. Measure the remaining tread depth with a caliper. If the tread depth is 1.6 mm or less, replace the tire.

8. Check the tightness of the wheel bolts and, if necessary, tighten them (tightening torque see annex 1).