1. Remove the camshaft from the car (see «Replacement of valve stem seals»).

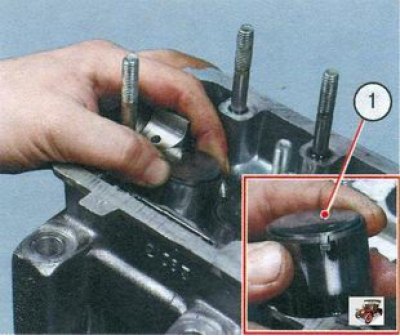

2. Remove the valve lifters together with shims 1.

Attention! Having taken out the next valve lifter, mark it and the adjusting washer with serial numbers in order to install them in their places during assembly. Unless necessary, do not remove the adjusting washers from the valve lifters, so as not to confuse them.

3. Inspect the valve lifters: there should be no scores or scratches on the cylindrical working surfaces of the pushers. Measure the outer diameters of the valve lifters with a micrometer. They should be equal to 35.275-35.295 mm.

4. Examine nests under pushers of valves in a head of the block of cylinders. On their surfaces, risks, scratches, scuffs, excessive one-sided wear are not allowed. Measure diameters of nests under pushers in a head of the block of cylinders. They should be 35.320-35.345 mm.

5. Calculate the gaps between the valve lifters and the sockets in the cylinder head by the difference in size. For new parts, the gaps should be 0.025-0.070 mm. If after operation the gaps exceed 0.1 mm, replace the valve lifters. If, even after replacing the valve lifters, the clearances exceed the maximum allowable value, replace the cylinder head.

6. Establish on the car pushers of valves, a camshaft and all removed details in an order, the return to removal.

7. Adjust valve clearances (see «Valve clearance adjustment»).

Note. Before installing the valve lifters in the sockets and the camshaft on the cylinder head, lubricate the working surfaces of the pushers, necks and camshaft cams with engine oil.