Car engine repair Lada Kalina 1

Reference data (engines 1.4i 16V and 1.6i 16V)

Table 8.1.1. Basic data for control, adjustment and maintenance Table 8.1.2. Tightening torques for threaded connections

Table 8.1.1. Basic data for control, adjustment and maintenance Table 8.1.2. Tightening torques for threaded connections

Description of the engine design

The vehicle is equipped with a 16-valve engine model 11194 or 21126*. Engines - gasoline, four-stroke, four-cylinder in-line with overhead camshafts and liquid cooling. The cylinder block is cast...

The vehicle is equipped with a 16-valve engine model 11194 or 21126*. Engines - gasoline, four-stroke, four-cylinder in-line with overhead camshafts and liquid cooling. The cylinder block is cast...

Checking the technical condition of the engine

The technical condition of the engine depends on the mileage of the car, the timeliness of periodic maintenance, the quality of the operating materials used, as well as the quality of the repair....

The technical condition of the engine depends on the mileage of the car, the timeliness of periodic maintenance, the quality of the operating materials used, as well as the quality of the repair....

Oil level — check

Recommendation. The check should be carried out 10-15 minutes after the engine has stopped. Execution sequence 1. We prepare the car for work (see « Preparing the car for maintenance and repair »)....

Recommendation. The check should be carried out 10-15 minutes after the engine has stopped. Execution sequence 1. We prepare the car for work (see « Preparing the car for maintenance and repair »)....

Engine oil and oil filter — change

The first oil change on a new or overhauled engine should be carried out after 2500-3500 km of run, then every 15,000 km. The volume of the lubrication system is 3.5 liters. Recommendation. For a...

The first oil change on a new or overhauled engine should be carried out after 2500-3500 km of run, then every 15,000 km. The volume of the lubrication system is 3.5 liters. Recommendation. For a...

Oil pressure — check

Recommendation. If, when the engine is warmed up to operating temperature at idle, the emergency oil pressure lamp lights up, then you need to make sure that: A) the oil level in the engine crankcase...

Recommendation. If, when the engine is warmed up to operating temperature at idle, the emergency oil pressure lamp lights up, then you need to make sure that: A) the oil level in the engine crankcase...

Decorative overlay of the engine — removal and installation

The decorative overlay is held by four rubber couplings put on the studs of the intake module cover. Removing 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2....

The decorative overlay is held by four rubber couplings put on the studs of the intake module cover. Removing 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2....

Compression in the engine cylinders — check

To perform the work, you will need an assistant, as well as a compression tester. Execution sequence 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2. We warm...

To perform the work, you will need an assistant, as well as a compression tester. Execution sequence 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2. We warm...

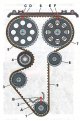

Timing Belt — Checking Condition

The timing belt should be checked during vehicle maintenance - every 15,000 km. Recommendation. If, when the engine is running, a strong rotating bearing noise is heard in the area of \u200b\u200bthe...

The timing belt should be checked during vehicle maintenance - every 15,000 km. Recommendation. If, when the engine is running, a strong rotating bearing noise is heard in the area of \u200b\u200bthe...

Timing belt — replacement

An assistant is required to complete the work, and it is also desirable to have a viewing ditch. Recommendation. Since valves and pistons may collide if the timing belt breaks, the timing belt must...

An assistant is required to complete the work, and it is also desirable to have a viewing ditch. Recommendation. Since valves and pistons may collide if the timing belt breaks, the timing belt must...

Timing belt tensioner and guide rollers — check and replace

Recommendation. If, when the engine is running, a strong rotating bearing noise is heard in the area under the front timing belt covers (see « Checking the technical condition of the engine »), the...

Recommendation. If, when the engine is running, a strong rotating bearing noise is heard in the area under the front timing belt covers (see « Checking the technical condition of the engine »), the...

Cylinder head cover — removal, cleaning of the oil deflector and installation

Removing 1. Remove the air filter (see « Air filter - removal and installation »). 2. Remove the engine trim (see « Decorative overlay of the engine - removal and installation »). 3. Remove the...

Removing 1. Remove the air filter (see « Air filter - removal and installation »). 2. Remove the engine trim (see « Decorative overlay of the engine - removal and installation »). 3. Remove the...

Camshaft seals — replacement

To do the job, you will need a special tool to hold the camshaft pulleys. Comment. Work can be done without this device if you can unscrew the bolts securing the camshaft pulleys. Execution sequence...

To do the job, you will need a special tool to hold the camshaft pulleys. Comment. Work can be done without this device if you can unscrew the bolts securing the camshaft pulleys. Execution sequence...

Camshafts — removal and installation

Removing 1. Remove the camshaft pulleys (see « Camshaft seals - replacement »). 2. Remove the tension and guide rollers (see « Timing belt tensioner and guide rollers - check and replace »). 3. Using...

Removing 1. Remove the camshaft pulleys (see « Camshaft seals - replacement »). 2. Remove the tension and guide rollers (see « Timing belt tensioner and guide rollers - check and replace »). 3. Using...

Hydropushers — removal and installation

Removing 1. Remove the camshafts (see « Camshafts - removal and installation »). When assembling the hydraulic pushers, it is recommended to install them in their original places. 2. We remove the...

Removing 1. Remove the camshafts (see « Camshafts - removal and installation »). When assembling the hydraulic pushers, it is recommended to install them in their original places. 2. We remove the...

Oil seals — replacement

Comment. Valve stem seals can be replaced without removing the cylinder head from the cylinder block. To dry out the valves, a compressor and an adapter with a hose for forcing air into the cylinder...

Comment. Valve stem seals can be replaced without removing the cylinder head from the cylinder block. To dry out the valves, a compressor and an adapter with a hose for forcing air into the cylinder...

Cylinder head — removal and installation

Comment. The cylinder head can be removed complete with camshafts and thermostat (to access the connecting rod and piston group, to replace the gasket, etc.). If the head is to be repaired, it is...

Comment. The cylinder head can be removed complete with camshafts and thermostat (to access the connecting rod and piston group, to replace the gasket, etc.). If the head is to be repaired, it is...

Cylinder head — checking and lapping valves

To complete the work you will need: a special template or a wide locksmith's ruler; a set of flat probes; valve grinding tool; rubbing paste. Examination 1. Remove the cylinder head (see « Cylinder...

To complete the work you will need: a special template or a wide locksmith's ruler; a set of flat probes; valve grinding tool; rubbing paste. Examination 1. Remove the cylinder head (see « Cylinder...

Front crankshaft oil seal — replacement

Removing 1. Remove the timing belt (see « Timing belt - replacement »). 2. Remove the toothed pulley from the crankshaft. 3. In order not to lose the key and not damage the new oil seal with it, use...

Removing 1. Remove the timing belt (see « Timing belt - replacement »). 2. Remove the toothed pulley from the crankshaft. 3. In order not to lose the key and not damage the new oil seal with it, use...

Flywheel — removal and installation

Removing 1. Remove the pressure and clutch discs (see « Clutch - replacement »). 2. In any available way, we mark the position of the flywheel on the shaft (it will make installation easier). 3....

Removing 1. Remove the pressure and clutch discs (see « Clutch - replacement »). 2. In any available way, we mark the position of the flywheel on the shaft (it will make installation easier). 3....

Rear crankshaft oil seal — replacement

Removing 1. Remove the flywheel (see « Flywheel - removal and installation »). When performing the following operation, do not scratch the working surface of the crankshaft. 2. With a special hook or...

Removing 1. Remove the flywheel (see « Flywheel - removal and installation »). When performing the following operation, do not scratch the working surface of the crankshaft. 2. With a special hook or...

Engine oil pan — removal, gasket replacement and installation

Removing 1. Remove the engine mudguard or crankcase protection (if installed). 2. Drain the oil from the engine (see « Engine oil and oil filter - change »). 3. Using a 10 mm socket wrench, unscrew...

Removing 1. Remove the engine mudguard or crankcase protection (if installed). 2. Drain the oil from the engine (see « Engine oil and oil filter - change »). 3. Using a 10 mm socket wrench, unscrew...

Oil intake — removal and installation

Removing 1. Remove the engine oil pan (see above, «Oil pan - removal, gasket replacement and installation»). 2. Using a 10 mm wrench, unscrew the two bolts 1 securing the oil intake to the main...

Removing 1. Remove the engine oil pan (see above, «Oil pan - removal, gasket replacement and installation»). 2. Using a 10 mm wrench, unscrew the two bolts 1 securing the oil intake to the main...

Oil pump — removal, inspection and installation

Removing 1. Remove the crankshaft pulley and its key (see « Front crankshaft oil seal - replacement »). 2. Remove the crankshaft position sensor (see « Crankshaft position sensor - removal,...

Removing 1. Remove the crankshaft pulley and its key (see « Front crankshaft oil seal - replacement »). 2. Remove the crankshaft position sensor (see « Crankshaft position sensor - removal,...

Piston rings and connecting rod bearings — replacement

Piston rings are replaced during the repair of the connecting rod and piston group, if they are worn or damaged. Also, the rings are replaced during the overhaul of the engine. You will need a piston...

Piston rings are replaced during the repair of the connecting rod and piston group, if they are worn or damaged. Also, the rings are replaced during the overhaul of the engine. You will need a piston...

Piston and connecting rod — replacement

Excessively worn pistons must be replaced. Replacing the piston and connecting rod may be required if the valve hits the piston, caused by a violation of the valve timing or a broken timing belt. To...

Excessively worn pistons must be replaced. Replacing the piston and connecting rod may be required if the valve hits the piston, caused by a violation of the valve timing or a broken timing belt. To...

Power unit mounts — replacement

To complete the work you will need: height-adjustable stand (e.g. screw jack); viewing ditch or overpass. Left support Removing 1. We prepare the car for work (see « Preparing the car for maintenance...

To complete the work you will need: height-adjustable stand (e.g. screw jack); viewing ditch or overpass. Left support Removing 1. We prepare the car for work (see « Preparing the car for maintenance...

Features of the device and repair of car modifications Lada Kalina

Table 16.1. Car modifications LADA KALINA * Some cars were fitted with the 11183 engine. Cars of the LADA KALINA family are produced with three body types: sedan, hatchback and station wagon, and are...

Table 16.1. Car modifications LADA KALINA * Some cars were fitted with the 11183 engine. Cars of the LADA KALINA family are produced with three body types: sedan, hatchback and station wagon, and are...

Features of the 1.6i engine device

The eight-valve engine with a working volume of 1.6 liters was created on the basis of the VAZ-2111 engine. It has a cylinder block increased in height by 2.3 mm and an original crankshaft. The...

The eight-valve engine with a working volume of 1.6 liters was created on the basis of the VAZ-2111 engine. It has a cylinder block increased in height by 2.3 mm and an original crankshaft. The...

1.6i engine lubrication system — checking the oil level

Recommendation. The check should be carried out 10-15 minutes after the engine has stopped. Execution sequence 1. We prepare the car for work (see « Preparing the car for maintenance and repair »)....

Recommendation. The check should be carried out 10-15 minutes after the engine has stopped. Execution sequence 1. We prepare the car for work (see « Preparing the car for maintenance and repair »)....

1.6i engine timing belt — checking condition and adjusting tension

The timing belt should be checked during vehicle maintenance - every 15,000 km. To do the job, you will need a wrench to tension the timing belt. Execution sequence 1. We prepare the car for work...

The timing belt should be checked during vehicle maintenance - every 15,000 km. To do the job, you will need a wrench to tension the timing belt. Execution sequence 1. We prepare the car for work...

1.6i engine timing belt — replacement

It is advisable to work with an assistant. Removing 1. Remove the front timing belt cover (see above, «1.6i engine timing belt - checking condition and adjusting tension»). 2. Remove the front right...

It is advisable to work with an assistant. Removing 1. Remove the front timing belt cover (see above, «1.6i engine timing belt - checking condition and adjusting tension»). 2. Remove the front right...

1.6i engine timing belt tensioner — removal and installation

Execution sequence 1. Remove the front timing belt cover (see « Timing belt for 1.6i engine - checking the condition and adjusting the tension »). Recommendation. When replacing the tensioner pulley...

Execution sequence 1. Remove the front timing belt cover (see « Timing belt for 1.6i engine - checking the condition and adjusting the tension »). Recommendation. When replacing the tensioner pulley...

1.6i engine camshaft oil seal — replacement

Execution sequence 1. Remove the timing belt (see « 1.6i engine timing belt - replacement »). 2. With a 10 mm socket wrench, put on the nut for fastening the rear cover of the timing belt, hold the...

Execution sequence 1. Remove the timing belt (see « 1.6i engine timing belt - replacement »). 2. With a 10 mm socket wrench, put on the nut for fastening the rear cover of the timing belt, hold the...

1.6i engine reservoir — removal, replacement of seals and installation

Removing 1. Remove the throttle assembly from the receiver flange studs without disconnecting the cooling system hoses from it (see « Throttle assembly - removal, gasket replacement and installation...

Removing 1. Remove the throttle assembly from the receiver flange studs without disconnecting the cooling system hoses from it (see « Throttle assembly - removal, gasket replacement and installation...

1.6i engine fuel rail — removal, disassembly, assembly and installation

The fuel rail is dismantled if necessary to remove the nozzles, as well as in other cases when repairing the engine. Removing 1. Relieve fuel pressure in the fuel line (see « Fuel Line - Pressure...

The fuel rail is dismantled if necessary to remove the nozzles, as well as in other cases when repairing the engine. Removing 1. Relieve fuel pressure in the fuel line (see « Fuel Line - Pressure...

1.6i engine intake and exhaust manifold gasket — replacement

To perform the work, an inspection ditch or overpass is required. Removing 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2. Using a 13 mm wrench, unscrew the...

To perform the work, an inspection ditch or overpass is required. Removing 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2. Using a 13 mm wrench, unscrew the...

1.6i engine cylinder head cover gasket — replacement

Removing 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2. Remove the decorative trim of the engine. 3. Disconnect the drive cable from the throttle and,...

Removing 1. We prepare the car for work (see « Preparing the car for maintenance and repair »). 2. Remove the decorative trim of the engine. 3. Disconnect the drive cable from the throttle and,...

Adjustment of clearances in the timing valve drive of the engine 1.6i

Comment. To compensate for the thermal expansion of the valve stem, a gap is required between the camshaft cam and the valve lifter. For intake valves, the clearance should be 0.15-0.25 mm, and for...

Comment. To compensate for the thermal expansion of the valve stem, a gap is required between the camshaft cam and the valve lifter. For intake valves, the clearance should be 0.15-0.25 mm, and for...

Engine camshaft 1.6i — removal and installation

Removing 1. Remove the timing belt (see « 1.6i engine timing belt - replacement »). 2. We unscrew the nut 1 and the bolt 2 of the upper fastening of the rear cover of the timing belt. 3. Disconnect...

Removing 1. Remove the timing belt (see « 1.6i engine timing belt - replacement »). 2. We unscrew the nut 1 and the bolt 2 of the upper fastening of the rear cover of the timing belt. 3. Disconnect...

1.6i engine valve stem seals — replacement

To complete the work you will need: tin rod; magnet; tweezers; oil seal remover; mandrel for pressing caps; cracker. Removing 1. Remove the camshaft (see « Engine camshaft 1.6i - removal and...

To complete the work you will need: tin rod; magnet; tweezers; oil seal remover; mandrel for pressing caps; cracker. Removing 1. Remove the camshaft (see « Engine camshaft 1.6i - removal and...

1.6i engine cylinder head — removal and installation

Removing 1. Drain the engine coolant (see « Coolant - replacement »). 2. Remove the tips of high-voltage wires from the candles. 3. Remove the cylinder head cover (see « 1.6i engine cylinder head...

Removing 1. Drain the engine coolant (see « Coolant - replacement »). 2. Remove the tips of high-voltage wires from the candles. 3. Remove the cylinder head cover (see « 1.6i engine cylinder head...

Piston rings and connecting rod bearings of the 1.6i engine — replacement

To do the job, you will need a mandrel for crimping the piston rings. Removing 1. Remove the cylinder head (see « 1.6i engine cylinder head - removal and installation »). 2. Remove the oil pickup...

To do the job, you will need a mandrel for crimping the piston rings. Removing 1. Remove the cylinder head (see « 1.6i engine cylinder head - removal and installation »). 2. Remove the oil pickup...

1.6i engine piston and connecting rod — replacement

To complete the work you will need: caliper; soft metal rod (∅ 21 mm). Disassembly 1. Remove the piston rings from the piston (see above). 2. With an awl, we hook and remove the piston pin retaining...

To complete the work you will need: caliper; soft metal rod (∅ 21 mm). Disassembly 1. Remove the piston rings from the piston (see above). 2. With an awl, we hook and remove the piston pin retaining...

High voltage wires — check and replacement

You will need a multimeter to test. Advice. In order not to confuse the leads on the ignition coil (ignition module), it is more convenient to change high-voltage wires one by one. Execution sequence...

You will need a multimeter to test. Advice. In order not to confuse the leads on the ignition coil (ignition module), it is more convenient to change high-voltage wires one by one. Execution sequence...

1.6i engine spark plugs — replacement

Spark plugs should be replaced every 30,000 km or when they fail if the engine becomes unstable at idle. On a 1.6i engine, spark plugs A17DVRM or their foreign counterparts - LR15YC should be used...

Spark plugs should be replaced every 30,000 km or when they fail if the engine becomes unstable at idle. On a 1.6i engine, spark plugs A17DVRM or their foreign counterparts - LR15YC should be used...

1.6i engine ignition coil — check and replace

Advice. For a quick check of the ignition system, you can use a spark indicator for engines with fuel injection. It is put on a spark plug and a high-voltage wire is connected to it. When checking,...

Advice. For a quick check of the ignition system, you can use a spark indicator for engines with fuel injection. It is put on a spark plug and a high-voltage wire is connected to it. When checking,...

This section is available on russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

More sections with information from manuals for Lada:

• Power unit: Engine repair Lada Granta 1 (2011-2023, VAZ-2190)

• Power unit: Engine repair Lada Priora 1 (2007-2018, VAZ-2170)

• Power unit: Engine repair Lada Vesta 1 (2015-2023, VAZ-2180)

• Power unit: Engine repair Lada Largus 1 (2012-2023)

Link to this section in various formats

TEXTHTMLBB Code

- General information

- Vehicle device

- Operation and maintenance

- Faults en route

- Power unit

- Engine repair

- Cooling and lubrication system

- Exhaust system

- Supply system

- Ignition and control

- Transmission

- Clutch and drive shafts

- Car gearbox

- Chassis (running gear)

- Front suspension

- Rear suspension

- Steering

- Brake system

- Body and interior

- Exterior (external elements)

- Interior (internal elements)

- Doors, locks and windows

- Electrical equipment

- Equipment and devices

- Power devices

- Lighting and signaling

- Heating and ventilation

- General information

- Vehicle Details

- Maintenance

- Troubleshooting

- Power unit

- Engine repair

- Cooling system

- Supply system

- Control system

- Exhaust system

- Transmission

- Clutch

- Car gearbox

- Drive shafts

- Chassis (running gear)

- Wheels and tires

- Front suspension

- Rear suspension

- Steering

- Brake system

- Body and interior

- Exterior (external elements)

- Interior (internal elements)

- Doors, locks and windows

- Electrical equipment

- Equipment and devices

- Power devices

- Lighting and signaling

- Electrical circuits