Comment. The cylinder head can be removed complete with camshafts and thermostat (to access the connecting rod and piston group, to replace the gasket, etc.). If the head is to be repaired, it is advisable to disassemble it as much as possible before dismantling it from the cylinder block.

An inspection ditch or overpass will be required to complete the job, as well as a new cylinder head gasket.

Removing

1. Drain the engine coolant (see «Coolant - replacement»).

Advice. If the connecting rod and piston group is to be repaired, it is advisable to immediately drain the oil from the crankcase.

2. Remove the engine trim (see «Decorative overlay of the engine - removal and installation»).

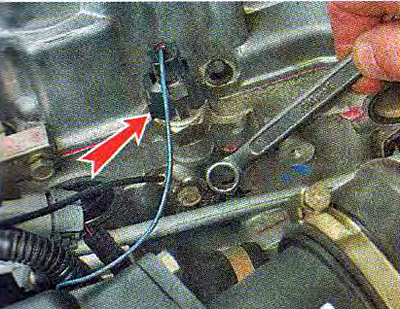

3. Using a 10 mm wrench, unscrew the bolt securing the wire tip «masses» and disconnect it from the block head. Disconnect the wiring harness from the emergency oil pressure sensor.

4. In order not to damage, disconnect the wire block from the coolant temperature sensor (see «Coolant Temperature Gauge Sensor - Check and Replace»).

5. Disconnect the thermostat housing from the cylinder head (see «Thermostat - removal, replacement and installation»).

6. Remove the cylinder head cover (see «Cylinder head cover - removal, cleaning of the oil deflector and installation»).

7. Remove the camshafts (see «Camshafts - removal and installation»).

8. We remove the hydraulic pushers from the mounting holes (see «Hydropushers - removal and installation»)

9. Remove the catalytic manifold (see «Catalytic manifold - removal, gasket replacement and installation»).

Comment. The camshaft position and temperature gauge sensors can not be removed, but you need to remove the head from the cylinder block carefully so as not to accidentally damage the sensors.

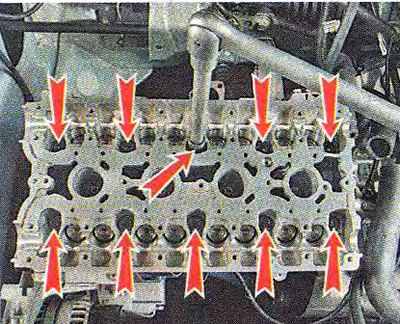

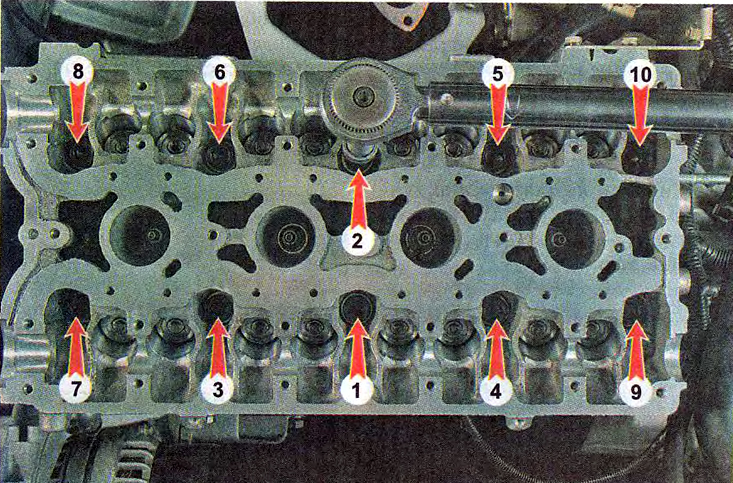

10. Evenly, in several stages, with a 10 mm hex wrench, unscrew the ten bolts of the cylinder head.

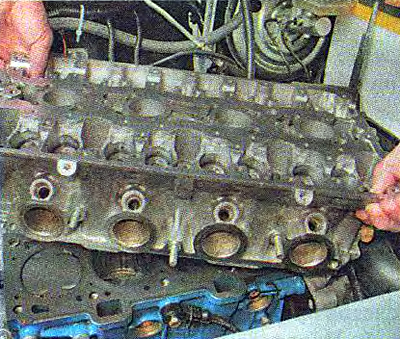

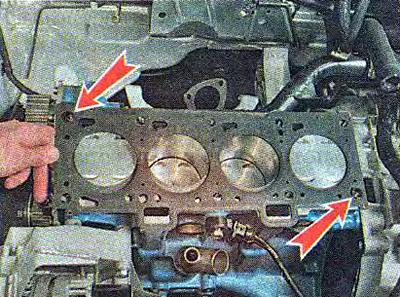

11. Remove the head from the cylinder block.

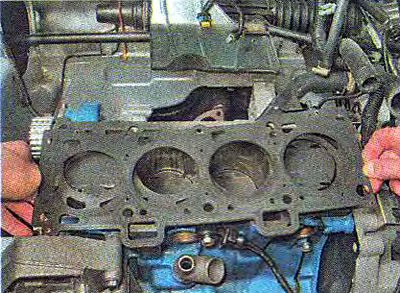

12. Remove the cylinder head gasket.

13. In order not to lose, we take out two guide bushings from the mounting holes in the cylinder block.

14. We wash the cylinder head from dirt and deposits with kerosene or diesel fuel.

Installation

1. Remove from the threaded holes of the cylinder block (for head bolts) residual oil and coolant.

2. We wipe the mating surfaces of the head and cylinder block with a cloth, degrease them with a solvent.

Warning! Always use a new gasket when installing the cylinder head. It is unacceptable to get oil on the surface of the gasket.

3. We install the guide bushings of the head in the seats of the cylinder block. We lay the gasket on the cylinder block, while the guide bushings must enter the corresponding holes in the gasket.

4. Install the head on the cylinder block. Slightly moving the head from side to side, we achieve that the guide bushings enter the corresponding recesses of the head.

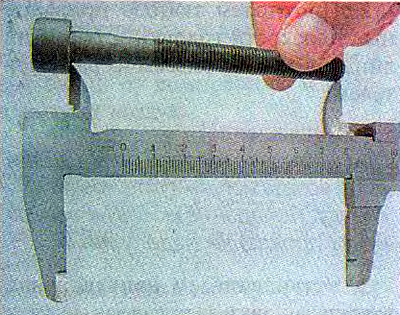

Warning! The cylinder head bolts may only be reused if their length does not exceed 100 mm.

Cylinder head bolt tightening sequence

5. We measure the length of the bolts with a caliper or locksmith's ruler. Bolts longer than 100 mm are replaceable.

6. Before installation, we dip the threaded part of the bolts into engine oil, after which we let the oil drain, after waiting about half an hour.

7. We install the bolts of its fastening into the holes of the head. Using a torque wrench, tighten the head mounting bolts in three stages - first with a torque of 20 Nm (2 kgf·m), then turn the bolts 90°and then turn the bolts 90°again. At the same time, we observe the sequence indicated in the photo (see above).

8. Further assembly of the engine is carried out in the reverse order of assembly.