Execution sequence

1. We prepare the car for work (see «Preparing the car for maintenance and repair»).

2. We warm up the engine to operating temperature and turn off the ignition.

3. We take out the fuses of the computer and the circuits of the engine management system (see «Fuses and relays of the engine management system»).

4. Relieve fuel pressure (see «Fuel Line - Pressure Relief»).

5. Turn out the spark plugs (see «Spark plugs - replacement»).

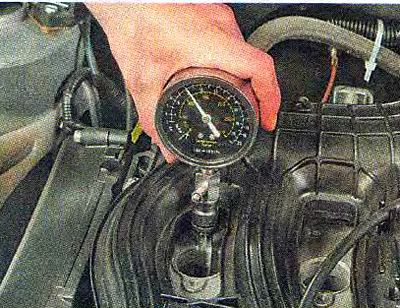

6. We install a compression gauge in the spark plug hole of one of the engine cylinders.

7. The assistant presses the gas pedal all the way to the floor (to fully open the throttle) and turns on the starter for 5-10 s.

Comment. Measurements must be taken with a fully charged battery, otherwise the readings will be incorrect.

8. We remember or write down the readings of the compression gauge and reset the device.

9. Similarly, we measure the compression in the three remaining cylinders.

For a serviceable engine, the compression in the cylinders must be at least 1.0 MPa (10 bar), and the difference in compression between the cylinders is no more than 0.1 MPa (1.0 bar).

10. If the compression is less, then pour about 10 cm3 of engine oil into the spark plug holes of the engine cylinders with low compression with a medical syringe or oil can.

11. Repeat the compression test. If the compression has increased, it is possible «lay down» rings or worn piston group (see «Piston rings and connecting rod bearings - replacement»). Otherwise, the valves do not close tightly or the cylinder head gasket is faulty.

Recommendation. You can try to eliminate valve sticking with special preparations poured into the fuel tank or directly into the engine cylinders (see «instruction» to the preparation). The tightness of the valves can be checked with compressed air at a pressure of 0.2-0.3 MPa (2-3 kgf/cm3), supplied through spark plug holes. It is necessary to supply air in such a position of the camshaft when both valves of the cylinder under test are closed. If the exhaust valve is faulty, air will exit through the exhaust system, and if the intake valve is faulty, through the throttle assembly. If the piston group is faulty, air will escape through the oil filler neck. The release of air bubbles through the coolant in the expansion tank indicates a malfunction of the cylinder head gasket.