Removing

1. Remove the crankshaft pulley and its key (see «Front crankshaft oil seal - replacement»).

2. Remove the crankshaft position sensor (see «Crankshaft position sensor - removal, inspection and installation»).

3. Remove the oil pickup (see «Oil intake - removal and installation»).

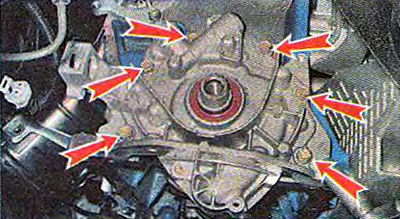

4. Using a 10 mm socket wrench, unscrew the six bolts securing the oil pump to the cylinder block.

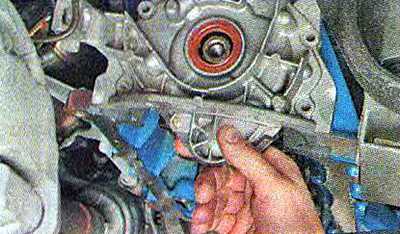

5. Remove the oil pump from the engine.

6. Remove the remnants of the gasket from the mating plane of the cylinder block.

Disassembly

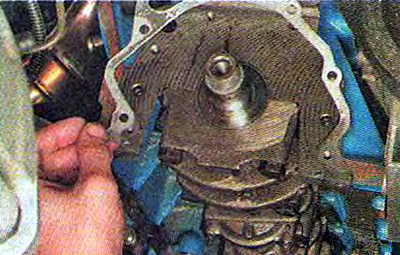

1. With a 5 mm hex wrench, unscrew the six bolts that tighten the pump housing and cover.

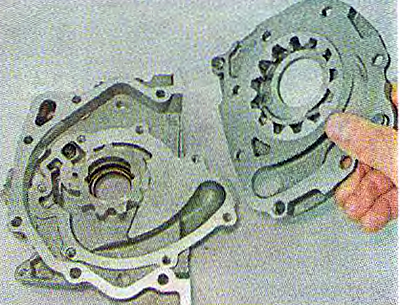

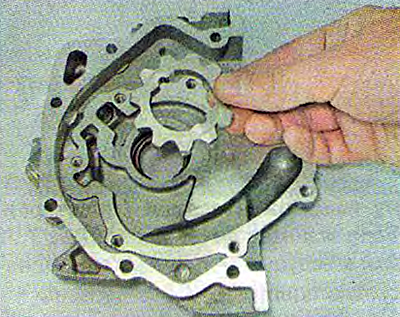

2. Disconnect the pump housing and cover.

3. We take out the drive gear from the cover.

4. We remove the driven gear from the housing.

Recommendation. Stopper reduction (safety) valve is over tightened. Unscrewing it can accidentally damage the pump cover. Also, turnkey edges are damaged on the cork itself. Therefore, do not disassemble the valve unless necessary. You can flush the valve without disassembling it.

5. We wash the pump parts with diesel fuel or kerosene, wipe dry and lubricate the gears with clean engine oil.

Examination

1. We inspect the parts of the oil pump. They should not show signs of heavy wear, metal heaping, cracks or other damage.

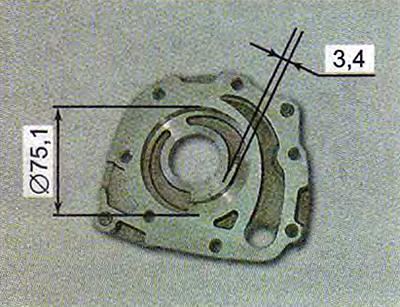

2. Using a caliper, we measure the diameter of the driven gear bore into the pump housing and the thickness of the partition between the driven and drive gears.

The diameter of the seat of the driven gear in the pump housing must not exceed 75.1 mm. The minimum thickness of the dividing wall between the driving and driven gears is 3.4 mm.

3. We measure the thickness of the driven and driving gears with a micrometer. If the driven gear is thinner than 7.35 mm, and the drive gear is 7.41 mm, then we replace the gears.

4. We put the drive gear into the oil pump housing. Having attached the edge of the locksmith's ruler to the mating surface of the oil pump housing, with a set of flat probes we determine the gap between the edge of the ruler and the gear. We repeat the test with the driven gear.

If the gap between the ruler and the drive gear is more than 0.12 mm (or 0.15 mm - for the driven), the gears need to be replaced.

Assembly

Advice. On a removed pump, it is recommended to replace the front crankshaft oil seal installed in the pump cover (see «Front crankshaft oil seal - replacement»).

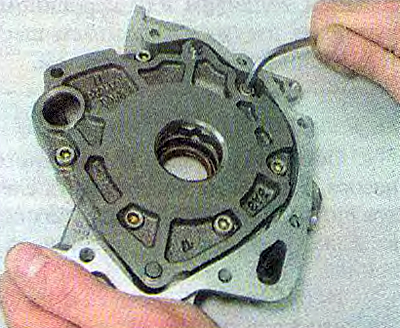

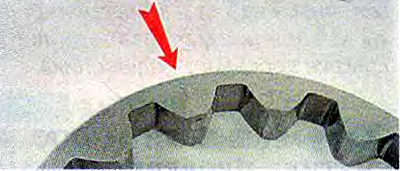

We assemble the pump in the reverse order of removal. In this case, the driven gear must be installed in the pump so that the side with the mark and chamfers on the teeth faces the housing.

The drive gear must be oriented during installation in the same way: chamfered on the teeth - to the pump housing.

Installation

We install the oil pump in the reverse order of removal, replacing the gasket between the pump and the cylinder block with a new one.