The cylinder block is cast iron, with cylinders machined in it. The internal cavities of the block for the coolant are formed during its casting, and the oil supply channels are made by drilling. At the bottom of the cylinder block are five crankshaft main bearings. The main bearing caps are not interchangeable and are marked with the bearing serial number starting from the crankshaft pulley. In the cover of the second main bearing, two threaded holes are made for the oil intake mounting bolts. Steel-aluminum liners of main bearings are installed in the supports and covers. On both sides of the third main bearing support, sockets are made for installing thrust half rings that prevent axial movement of the crankshaft. The front semi-ring is steel-aluminum, the rear is ceramic-metal, yellow on both sides.

Engines 11194 and 21126 differ from previous models in a lightweight connecting rod and piston group.

Pistons with a short skirt, cast aluminum alloy. Four small grooves are made in the bottom of each piston for the valve plates, but they do not prevent the valve from contacting the piston in case of a valve timing violation or a broken timing belt. Each piston has two compression rings and one oil scraper ring. Lower compression ring of scraper type with a groove and a sharp edge on the lower plane. A spring expander is installed inside the oil scraper ring. All rings are thinner than previous engine models to reduce internal engine friction losses.

The fingers are of a floating type, fixed in the pistons with two spring retaining rings.

Connecting rods - «stab» **. A steel-bronze bushing is pressed into the upper head of the connecting rod. The connecting rod caps are not interchangeable and only fit in one position on the connecting rod.

From below, the crankcase is attached to the cylinder block.

Combined engine lubrication system - under pressure and spray. The oil pump is an internal gear type driven by the front end of the crankshaft. Through the oil intake, the pump takes oil from the oil pan and pumps it under pressure into the channels of the engine lubrication system. To control the amount of oil in the sump, a measuring probe is installed - a level indicator. Oil filter - full-flow, with a paper filter element and a check valve that prevents oil from flowing out of the lubrication system channels into the oil pan after the engine is stopped.

* Features of the device, maintenance and repair of the 8-valve engine are described in the chapter «Features of the device and repair of modifications of the car LADA KALINA» (see p. 207).

** The connecting rod and its cover are first made as a single (one-piece) detail. After making holes in the upper and lower heads of the connecting rod, using a special method «split» lower head. This technology allows you to get the perfect connection between the cap and the connecting rod.

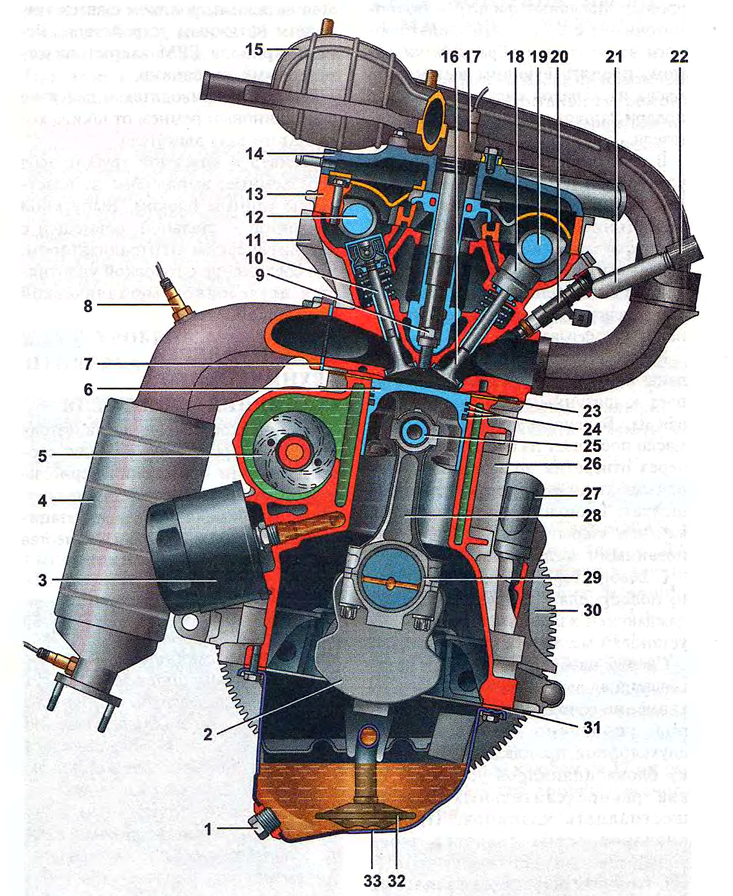

Cross section of a 16-valve engine*:

1 - drain plug of the oil pan;

2 - crankshaft;

3 - oil filter;

4 - catalytic manifold;

5 - coolant pump;

6 - piston;

7 - catalytic manifold gasket;

8 - oxygen concentration sensor;

9 - spark plug;

10 - exhaust valve;

11 - cylinder head;

12 - exhaust camshaft;

13 - camshaft bearing housing;

14 - cylinder head cover;

15 - inlet module;

16 - inlet valve;

17 - ignition coil;

18 - hydraulic pusher;

19 - intake camshaft;

20 - nozzle;

22 - diagnostic fitting of the fuel rail;

21 - fuel rail;

23 - cylinder head gasket;

24 - piston rings;

25 - piston pin;

26 - cylinder block;

27 - fitting of the crankcase ventilation system;

28 - connecting rod;

29 - connecting rod bearings;

30 - flywheel;

31 - gasket of the oil pan;

32 - oil intake;

33 - engine oil pan.

Oil jets are installed in the main bearings. Oil from the nozzles is supplied to the internal surfaces of the pistons to cool them. Part of the oil falls on the upper heads of the connecting rods and flows through the conical holes made in them onto the piston pins, lubricating them.

Channels are drilled in the body of the crankshaft. Oil flows through them to the connecting rod journals, lubricating them. Oil enters the crankshaft channels from the cylinder block through holes in the main bearing shells and main journals. Technological openings of the channels are closed with stamped steel plugs.

On the left side of the block there is a cavity for installing a coolant pump and a tide for installing an oil filter.

An aluminum head is mounted on top of the cylinder block. The connection between the head and the cylinder block is sealed with a metal two-layer gasket. The cylinder head has two camshafts and sixteen valves. The valve drive is carried out through pushers, with hydraulic compensators. Therefore, adjustment of thermal gaps in the valve actuator is not required. The intake and exhaust camshafts are not interchangeable. The camshaft bearings are made in the head, and their covers are combined into a bearing housing mounted on the head. From above, the bearing housing is closed with a block head cover with an oil deflector and an oil filler neck. To install spark plugs on top of the cylinder head, cylindrical recesses are made - candle wells. An ignition coil is inserted into each well, while the high-voltage output of the coil is put on the spark plug.

The drive of the camshafts and the coolant pump is carried out by a toothed belt from the crankshaft of the engine. To guide the belt along the pulleys, a guide roller is installed, the belt is tensioned by a tension roller with an automatic tensioner. The timing belt is covered with plastic covers.

The generator is driven by a V-ribbed belt from the engine crankshaft pulley.

The receiver and the inlet pipeline are one-piece, made of plastic as a single unit. The exhaust manifold is steel, combined with a catalytic converter. Its connection with the head is sealed with a two-layer metal gasket.