Removing

1. Remove the cylinder head (see «1.6i engine cylinder head - removal and installation»).

2. Remove the oil pickup (see «Oil intake - removal and installation»).

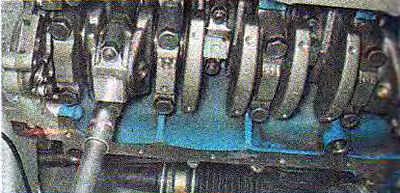

3. Turning the crankshaft clockwise, set the piston of the first cylinder to the lower position.

4. Using a 14 mm socket wrench, unscrew the two nuts securing the cover of the connecting rod of the first cylinder and remove the connecting rod cover.

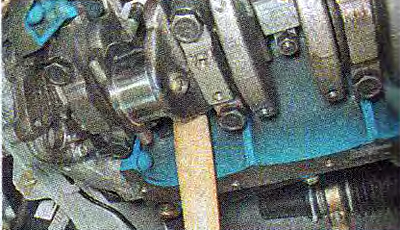

5. Having rested the hammer handle on the piston, push it up and remove the piston from the cylinder.

6. We take out an insert from a rod and its cover.

Warning! When disassembling the connecting rod, do not press the bolts out of it.

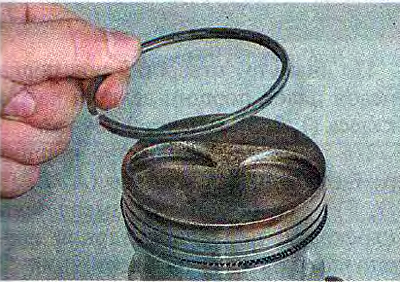

7. We clamp the piston by the connecting rod in a vice.

8. Slightly spreading the lock of the ring, remove the upper compression ring.

9. Similarly, remove the lower compression ring.

10. Remove the oil scraper ring...

... and its expander.

Installation

1. Thoroughly clean the piston from carbon deposits and deposits. We examine the piston and connecting rod. Cracks are unacceptable.

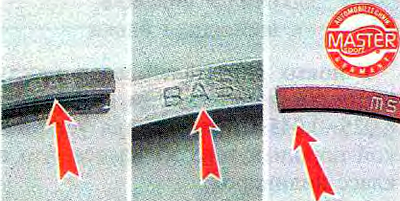

2. We select new rings in accordance with the piston diameter - nominal or repair size. There are no designations on rings of nominal size, repair rings are increased in diameter by 0.4 or 0.8 mm and are marked «40» And «80» respectively.

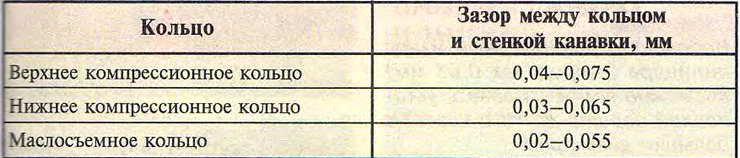

3. Before installing new rings with a set of probes, we measure the gap between the piston ring and the groove wall into which the ring will be installed.

If the clearance exceeds the maximum allowable (see table. 16.3), the piston must be replaced.

The oil scraper ring and the upper compression ring are installed with inscriptions «TOR», «VAZ» or another up.

We orient the lower compression ring in such a way that it is directed downwards with a groove or with an inscription «TOR» up.

1. We put the rings on the piston as follows: by pushing the ring lock (no more than is required to put the ring on the piston), we start the lock on the piston first, and then the back of the ring.

We install new rings on the piston, starting with the oil scraper ring expander. After installing the oil scraper ring, the expander lock must be rotated 180°relative to the ring lock.

After installing the rings on the piston, we turn them with locks so that the lock of the upper compression ring is located at an angle of 45°to the axis of the piston pin, the lock of the lower compression ring is turned 180°, and the lock of the oil scraper ring is 90°relative to the lock of the upper compression ring.

2. Lubricate the piston, rings and the inner surface of the cylinder with clean engine oil.

3. We put the mandrel on the piston and crimp the rings with it, periodically tapping the mandrel for self-alignment of the rings with the hammer handle.

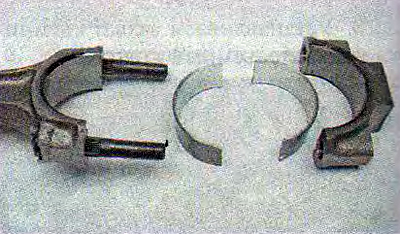

4. We wipe dry the bed liners in the connecting rod and the cover and install the liners in the lower head of the connecting rod.

5. Lubricate the inner surfaces of the liners and the connecting rod neck of the crankshaft with clean engine oil. By turning the crankshaft, we move the neck to the lowest position.

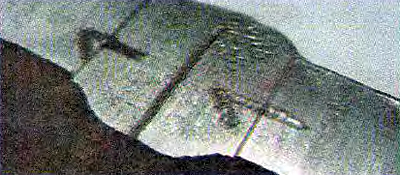

6. We install the piston on the block and orient it so that the arrow on the piston bottom is directed towards the crankshaft pulley (see below).

7. Pressing the mandrel against the block and tapping the piston bottom with the hammer handle, we sink it into the cylinder, while simultaneously monitoring the progress of the connecting rod to the crankshaft journal.

8. We install the cover assembly with the insert on the connecting rod and tighten its nuts to a torque of 43.32-53.51 Nm (4.42-5.46 kgf·m).

Warning! The connecting rod caps are not interchangeable. The connecting rod and its cap are marked with the number of the cylinder in which the connecting rod is to be installed. On the assembled connecting rod, the numbers should be located on one side.

We replace the rings of the other three pistons in the same way.

After installing all the pistons, we assemble the engine in the reverse order of disassembly.