Removing

1. Remove the camshaft pulleys (see «Camshaft seals - replacement»).

2. Remove the tension and guide rollers (see «Timing belt tensioner and guide rollers - check and replace»).

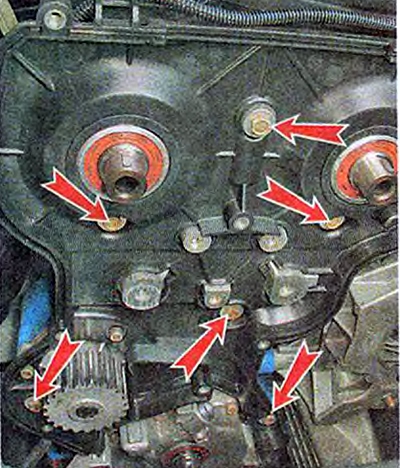

3. Using a 10 mm socket wrench, unscrew the six bolts securing the rear cover of the timing belt.

4. Remove the cover.

5. Remove the cylinder head cover (see «Cylinder head cover - removal, cleaning of the oil deflector, installation»).

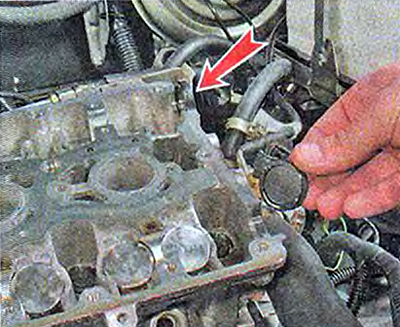

6. In order not to damage, remove the oil pressure sensor (see «Emergency oil pressure sensor - replacement»), or disconnect the wire tip from it.

7. Using an 8 mm socket wrench, evenly, half a turn, unscrew the 20 bolts securing the camshaft bearing housing.

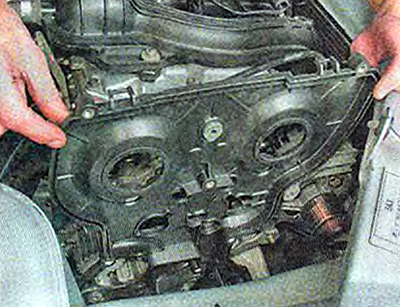

8. Remove the camshaft bearing housing.

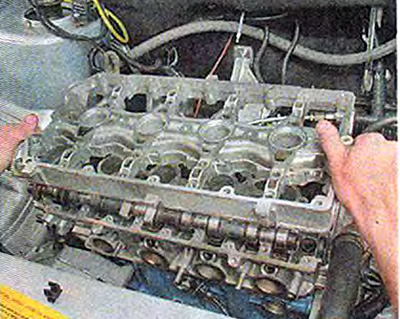

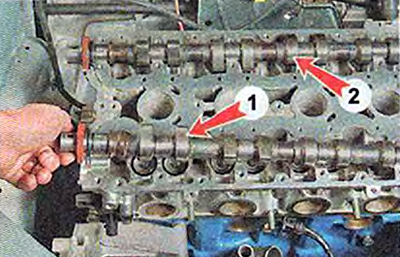

9. Remove the intake camshaft 1 and exhaust camshaft 2.

10. We take out two plugs of technological holes from the mounting holes in the head of the block (near the rear ends of the camshafts).

11. Remove the keys and seals from the shafts.

12. We examine the shafts. On the necks and cams of the shaft, there should not be signs of heavy wear, scratches, cracks, traces of metal enveloping.

Installation

1. Lubricate the bearing journals and shaft cams with clean engine oil.

2. We put the camshafts in the cylinder head. Shafts are not interchangeable and are marked.

The exhaust valve shaft is marked 1006014.

Inlet valve shaft marked 1006015.

In addition, the intake valve shaft has an additional belt.

Attention!

- When repairing the engine, do not use a sealant with a high content of silicone (silicon compounds), whose vapors can get through the crankcase ventilation system into the cylinders and further into the exhaust tract. Use a sealant specifically labeled as safe for the oxygen sensor.

- Do not apply too much sealant to the mating surfaces of the bearing housing. When tightening the mounting bolts, the sealant squeezed into the internal cavities of the engine can clog the oil channels.

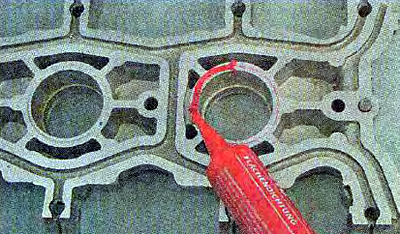

3. We also apply a thin layer of Loktite-574 sealant to the lower surface of the bearing housing around the holes of the candle wells, as well as...

... and on the plane of the cylinder head according to the following scheme:

4. We install the camshafts in the cylinder head with the keyways up.

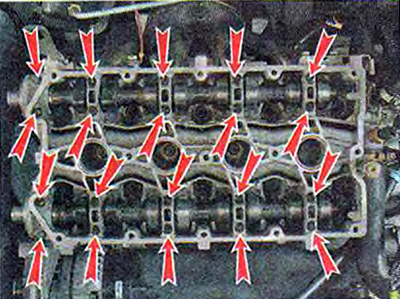

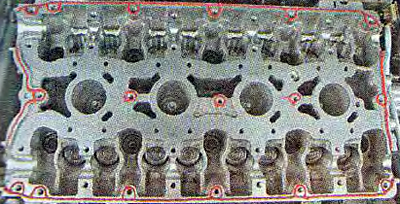

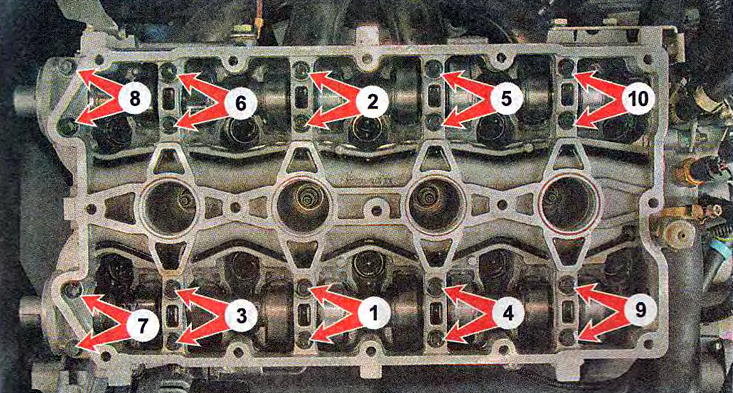

5. We install the bearing housing on the cylinder head and evenly tighten the bolts of its fastening until the bearing housing contacts the cylinder head. We finally tighten the bearing housing mounting bolts in pairs, with a torque of 8.0-10.0 Nm (0.8-1.0 kgf·m) in the sequence shown in the photo (see below).

6. With a rag, remove excess sealant squeezed out of the gap between the cylinder head and the bearing housing cover.

7. We press in the camshaft seals (see «Camshaft seals - replacement»).

8. We press two plugs into the cylinder head.

9. Further assembly is carried out in the reverse order of disassembly.

The sequence of tightening the bolts of the bearing housings