Removing

Place the vehicle on a two-post lift, apply the parking brake and turn off the ignition.

Remove front wheel.

Raise the vehicle to a height convenient for work.

Clean Front Brake Parts (metal brush).

Remove the front brake hose.

For cars LADA LARGUS R90 with K7M engine

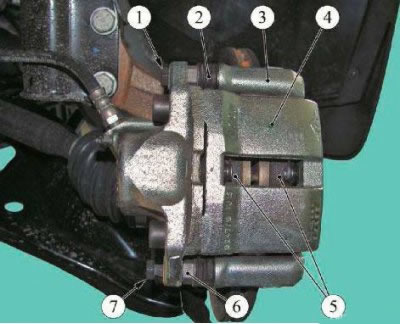

Figure 8-1 - Front brake caliper: 1, 7 - bolts for fastening the guide pins; 2 - protective cover for the guide pin; 3 - front brake guide; 4 - support; 5 - brake pads; 6 - guide pin

Unscrew and remove the bolts 1 and 7, Figure 8-1, fastening the guide pins, while holding the guide pins 6 with a wrench (wrench 17, interchangeable head 13, ratchet wrench).

Remove the front brake caliper.

For LADA LARGUS R90 cars with K4M engine and LADA LARGUS F90 cars

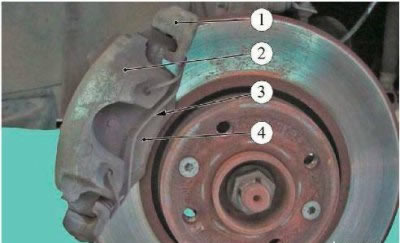

Figure 8-3: 1 - front brake guide; 2 - support; 3 - caliper spring; 4 - brake pads

Remove the spring 3, Figure 8-3 from the bores of the front brake caliper 2 (flathead screwdriver, pliers).

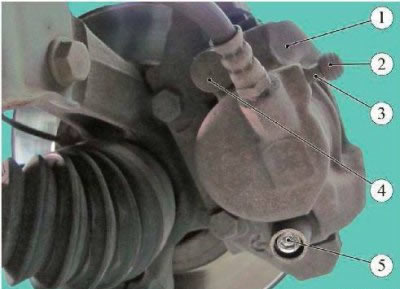

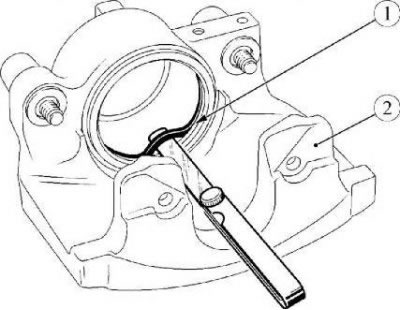

Figure 8-4: 1 - support; 2 - protective cap of the bleed valve; 3 - bleed valve; 4 - protective cap of the guide pin; 5 - guide pin

Remove the protective caps 4, Figure 8-4, from the wells of the guide pins (flat screwdriver).

Unscrew and remove guide pins 5 (replaceable nozzle with external hexagon type 7 "INHEX" 03 05 00 07 f. "Stahlwille", ratchet key).

Remove the front brake caliper.

Repair

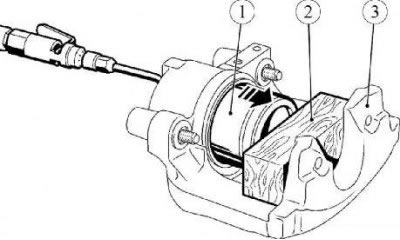

Figure 9-1 - Front brake caliper: 1 - piston; 2 - technological gasket; 3 - support

Remove the piston dust cap.

Remove piston 1, Figure 9-1, from the cylinder by blowing compressed air through the hole for connecting the brake hose, after inserting a wooden block 2 between the caliper and piston to avoid damaging the piston (air dispensing gun, technological gasket).

Remove O-ring 1 from the cylinder groove, Figure 9-2 (flat head screwdriver).

Figure 9-2 - O-ring replacement: 1 - sealing ring; 2 - support

Attention. If there are scratches or other damage on the piston skirt or cylinder bore, replace the caliper assembly.

Rinse the caliper parts with white spirit (cleaning rags, washing liquid white spirit).

Install a new O-ring into the cylinder groove.

Apply 1.5 g of Castrol S-058 or PFG-111 grease to the piston skirt and the inside of the protective cap, insert the piston into the cylinder and move it inward until it stops. Install protective cap (grease Castrol S-058 or PFG-111 according to the current "Codifier of the main and auxiliary materials used in the maintenance and repair of LADA vehicles" K 3100.25100.00018).

Installation

For cars LADA LARGUS R90 with K7M engine

Attention. After removing the bolts 1, 7, Figure 8-1, the fastenings of the guide pins must be replaced, since the fixation of the bolts is carried out with an adhesive composition applied to the threaded surface of the bolts. Bolts must not be reused.

Install the front brake caliper on the guide and fix it with new bolts for fastening the guide pins, first apply adhesive to the threaded surface of the bolts "FRENETANCHE" in the amount of 1 g for each bolt. Bolt tightening torque 34 Nm (3.4 kgf·m) (wrench 17, interchangeable head 13, ratchet wrench, torque wrench, glue "FRENETANCHE" spare part number 77 11 236 471).

For LADA LARGUS R90 cars with K4M engine and LADA LARGUS F90 cars

Install the front brake caliper on the guide and secure it with guide pins. Tightening torque for guide pins 28 Nm (2.8 kgf·m) (replaceable nozzle with external hexagon type 7 "INHEX" 03 05 00 07 f. "Stahlwille", ratchet wrench, torque wrench).

Install the protective caps in the wells of the guide pins.

Install the spring into the holes in the caliper (pliers, flat head screwdriver).

Install the front brake hose.

Install the front wheel.

Bleed the brake system and, if necessary, the hydraulic clutch.

Check the efficiency of the service brake system.

Addition

The caliper body is made from a cast blank, which is why it is the most reliable component. Even being recycled (restoration), which is the norm in developed countries, the caliper most often retains its properties. In Russia, by the way, it is also customary to restore calipers, but most often by artisanal methods.

Nevertheless, the thing is reliable, and most of the problems are associated with the moving parts of the part. This is especially true of floating structures, where the most «weak link» - guide pins.

It makes sense to make it a rule - to combine every second replacement of brake pads with the prevention of calipers. By preventive maintenance, we mean a close inspection of the guide pins and checking the mobility of the guide bracket (in floating structures), checking the brake cylinders, be sure to check the integrity of all anthers, seals and cuffs. And if at least one of these points is defective, it is necessary to carry out repairs.

Moreover, today you can find a repair kit for almost every caliper, both original kits and kits from famous manufacturers of decent quality are available.

Wedged guides are also solved using repair kits (just do not forget to thoroughly clean them first, or better, replace them with new ones, they are also on sale), and wedging pistons (pistons can also be found separately), and individual problems with the hydraulic circuit, although, as practice shows, problems with the hydraulic system are extremely rare.

The main thing, we repeat, is to regularly check the integrity of anthers and other «rubber bands». Dirt, moisture, and days of wear and tear entering through cracks can kill caliper components. And even if today the finger walks normally, then tomorrow, due to a crack in the anther, it is tightly «grab». As a result, the pad will stop wrung out, the disc will overheat and the penny anther will cause costly repairs or an accident.

Caliper Lubrication

The most fundamental point regarding caliper maintenance is lubrication. The guide pins must only be processed with a special lubricant. Since the caliper operates at high temperatures, the most popular mineral oil based lubricants are not suitable - they will melt and run off.

It is impossible to use not only lithol or grease, but even ceramic and copper lubricants, since they all damage rubber: anthers lose their fit properties. Therefore, only special lubricants designed for calipers are used.

By following all these recommendations and performing the steps described above, you will ensure the performance of the brakes for the period prescribed for it.