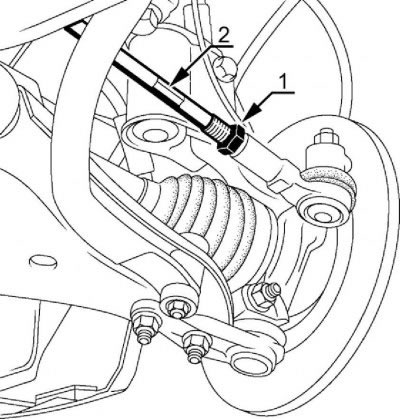

Figure 10 - Adjusting the toe of the front wheels of LADA LARGUS R90 and F90 cars: 1 - locknut for adjusting wheel alignment; 2 - steering trapezoid linkage

Table 1

| Automobile model | Tire size | Air pressure in tires, MPa (kgf/cm2) | |

| front wheels | rear wheels | ||

| LADA Largus R90 | 185/70 R14, 185/65 R15 | 0,24=0,01 (2,4=0,1) | 0,26=0,01 (2,6=0,1) |

| LADA Largus F90 | 185/65 R15 | 0,24=0,01 (2,4=0,1) | 0,30=0,01 (3,0=0,1) |

Table 2

| Automobile model | Front wheel alignment angles: | |||||||

| Vehicle under load | Curb car | |||||||

| Wheel camber, deg. | The angle of the longitudinal inclination of the axis of rotation of the wheels, deg. | Wheel alignment: | Wheel camber, deg. | The angle of the longitudinal inclination of the axis of rotation of the wheels, deg. | Wheel alignment: | |||

| Linear, mm | Angular, deg. | Linear, mm | Angular, deg. | |||||

| R90, F90 | - | - | - | - | -0°10=40' | 2°42'±30' * | - | -0°40'..0°20' |

Table 3

| Angles of installation of back wheels of the equipped car | ||

| Automobile model | Wheel camber, deg. | Convergence of wheels, hail. |

| LADA Largus R90, F90 | -0 o 51±15' | +0 o 44'±15' |

1. On LADA R90 and F90 cars, the angle of longitudinal inclination of the steering axis and the camber of the front wheels are incorporated into the vehicle design and are not subject to adjustment; suspension attachment points to the body. If necessary, replace damaged parts of the front suspension and eliminate deviations in the geometry of the body.

2. Adjust the toe-in of the front wheels of LADA R90 and F90 cars.

2.1. Set the steering wheel to the straight ahead position.

2.2. Loosen locknuts 1, Figure 10, while holding tie rod couplings 2 with a wrench (wrenches 13, 21).

2.3. By turning couplings 2, set the length of the steering rods, at which the toe-in of the front wheels will correspond to the parameters given in Table 2. After adjusting the lengths of the steering rods, the steering wheel should be in a position corresponding to straight-line movement (wrench 13).

2.4. Tighten locknuts 1 for steering linkage. Locknut tightening torque 50 Nm (5.0 kgf·m) (wrenches 13, 21, torque wrench and interchangeable insert type 819V21 f. USAG).

2.5. Check the alignment of the front wheels. The values of the front wheel alignment angles are given in table 2. When checking under load, the applied load should be: - 320±5 kgf. The test must be carried out in accordance with the operating instructions for the instrument. If the values of the parameters given in Table 2 deviate, adjust them.

About rear wheel alignment

The rear wheel alignment on the Largus is not adjustable. This is not provided for by either the regulations or the design of the car. But they can be measured! (see table above) And in view of the fact that many cars have broken corners (for different reasons), car owners use a method that consists in placing 2 washers of the desired thickness (thickness is selected individually), between the brake flap and the rear beam, on the individual side for each specific case.

The algorithm is something like this: wheel alignment is measured (or simply assessed independently, based on uneven tire wear). It is determined which bolts to unscrew to insert the washers, the thickness of the washers is approximately estimated.

Take off the wheel. The stem does not need to be removed. A Torx E16 socket is used to open the brake shield bolts. unscrewed (but not to the end) all four bolts. The shield moves away, as far as the bolts allow, from the beam. Only those two bolts are completely unscrewed, from the side of which the washers will be placed. Bolts are pulled out, washers are slipped with a thin tool (see photo), the bolts are inserted into place. Everything is going. And again, the similarity-collapse is measured. If adjustments are needed, the procedure is repeated.