Which spark plugs to use: The manufacturer Lada Largus recommends installing spark plugs EYQUEM RFC58LZ2E or SAGEM RFN58LZ, as well as CHAMPION RC87YCL. You can see the catalog numbers of regular candles Here.

Replacement for 8 cells. engine

|  |

When replacing spark plugs, keep clean at all stages of work, remove dirt around the spark plug well. Remove the tip of the high-voltage wire, and unscrew the spark plug with a spark plug wrench, or a high head "at 16". A new candle is carefully screwed into a clean well. In this case, only the force on the key is used (those. without a wrench, so as not to damage the motor threads with excessive force)

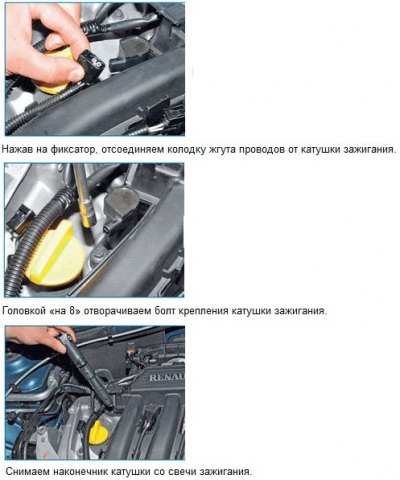

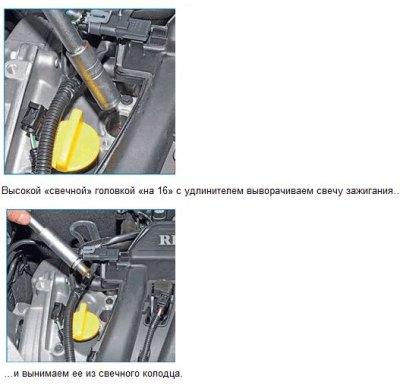

Replacement on a 16 valve engine

Installation of candles is similar to that described above 8-cl. dv.

Description, types of candles and related information

In parts stores you can find a huge variety of spark plugs. The share of imported products, according to the most conservative estimates, reaches 30%, and in some regions even higher. This is largely due to the increase in the number of cars imported from abroad. As a rule, candles of foreign firms are installed on them. Candles of domestic production are significantly cheaper than imported ones, but their use on foreign cars is limited, despite the economic and technical feasibility. There are many reasons for this phenomenon, but three main ones can be distinguished.

The range of production of candles in the former USSR was significantly limited, the technical level of products was inferior to the world. A significant share in the production volume was occupied by candles of obsolete designs, made using the technologies of the 50s and 60s. At the beginning of perestroika, against the backdrop of a general decline in production in the country, the quality of products deteriorated. As a result, many consumers have the opinion that domestic candles are less reliable than foreign ones.

The second reason is that the operating conditions on domestic cars. where Russian-made spark plugs are mainly used, it is much tougher than on foreign cars, given the actual technical condition of this sector of the fleet and the quality of the fuels and motor oils used. Experience in using foreign-made candles has shown that their reliability when used on domestic cars, especially not new ones, is also significantly reduced, even if the correct selection is made according to the thermal characteristic.

It is very significant that the amount of information intended for most candle consumers is clearly insufficient. The available technical information is of a specific nature and is contained in standards and nomenclature reference books that are not easily accessible to the general reader. Unlike foreign firms, domestic manufacturers are only mastering the production of brochures and catalogs.

Consumers are not sufficiently informed that at present, due to the growing demand, the production of spark plugs in Russia is actively developing. The product range is expanding to meet the needs of the domestic and foreign markets. The volume of exports to countries not only near, but also far abroad is increasing. Most of the currently produced domestic candles correspond to foreign analogues in terms of quality and technical level.

Pic. 1. Shielded (1,2) and unshielded (3-8) spark plugs: 1 - CH307B: 2 - CH302A. 3 - A17DV-Yu: 4 - A20DV-g. 5 - A17DVRM; 6 - A178; 7 - A11-5; 8 - AU17D8RM

Candles are the most important element of the ignition systems of internal combustion engines. They are designed to ignite the combustible mixture in the cylinders using a spark discharge. Spark discharge generated by the system

ignition, must have the energy necessary to ignite the combustible mixture in any mode of engine operation under all operating conditions.

Candles vary in design, size and thermal characteristics (heat numbers). They may not be shielded. when their contact part protrudes from the metal case, and shielded, in which the contact part is located inside the metal shield (fig.1).

The spark discharge in most candles is formed directly in the spark gap between the electrodes. With a sliding spark, the discharge occurs on the surface of an insulator installed between the electrodes. There are candles with a combined discharge, in which one part of the spark is formed between the electrodes, and the other - along the surface of the insulator.

At high pressures and temperatures that occur during engine operation, spark plugs must reliably withstand the effects of chemically aggressive combustion products. In this case, the insulator must withstand high electrical voltage.

During operation, due to incomplete combustion in the near-wall zone, carbon deposits form on the working parts of the spark plug. Due to the possibility of shunting the ignition system and failure of sparking, candles must be self-cleaning, automatically maintaining the required operating temperature within a temperature range that ensures the removal of carbon deposits and excludes the possibility of glow ignition.

Candles must ensure their performance in conditions where electrical, mechanical and chemical loads compete with each other in their intensity. For the entire service life of the spark plugs must withstand tens of millions of operating cycles. The continuous increase in the specific power of engines with the tightening of exhaust gas toxicity standards imposes increasingly stringent requirements on reliability and durability for spark plugs.

Its starting properties, reliability, power, fuel efficiency, and exhaust gas toxicity significantly depend on the perfection of design, workmanship and the correct selection of a spark plug for an engine.

In turn, the performance of a spark plug depends on its compliance with the engine in terms of design, main dimensions, spark gap and thermal characteristics. The technical condition of the engine, the nature and conditions of operation, the quality of fuel and engine oil have a decisive influence on the reliability and durability of the spark plug.

Domestic manufacturers of spark plugs are able to fully provide the domestic market and traditional export supplies with high-quality modern products in the required range. A feature of the current stage of development of the domestic production of candles is that, along with large specialized enterprises that manufacture tens of millions of candles a year. there are smaller manufacturers. An important factor in creating a competitive environment is that some foreign firms not only import finished products, but also master the production of candles in Russia.

Special terms

The upper temperature limit of the thermal characteristic is a value equal to the operating temperature of the candle at which glow ignition occurs.

«hot» or «cold» candles, ceteris paribus, having a correspondingly higher or lower operating temperature.

Detonation is an abnormal combustion process that has an explosive character with a sharp local increase in temperature and the formation of a shock wave. Accompanied by a ringing metallic knock caused by vibration of engine parts.

Sparking - the occurrence of a spark discharge in the spark gap of a candle in the period from breakdown to extinction.

spark plug (spark plug, candle) - an electrical input in combination with a spark gap, designed to ignite the combustible mixture in the engine cylinder by means of a spark discharge in the gap between the electrodes.

Spark gap - the gap between the insulated central electrode and the ground ground electrode.

spark discharge (electrical spark, spark) - non-stationary electric discharge in a gas that occurs in an electric field.

Glow ignition - ignition of a combustible mixture caused by separate overheated areas of the surfaces of the exhaust valve, piston, cylinder or spark plug.

The glow number of a candle is a conditional value, numerically equal to the average indicator pressure in the engine cylinder of the test installation, at which glow ignition appears.

The contact part of the candle - elements from the side of the high-voltage wire: insulator head, contact head and contact nut.

Nagar - products of incomplete combustion formed on the surface of the working part of the candle.

The lower temperature limit of the thermal characteristic is a value equal to the temperature of the working part of the candle at which the carbon burns out.

Candle performance - ensuring uninterrupted sparking and tightness under the conditions provided for by regulatory and technical documentation and standards.

The working chamber of the spark plug is a cavity formed by the inner surface of the housing and the outer surface of the thermal cone of the insulator, which communicates with the combustion chamber of the engine.

The working temperature of the spark plug is the temperature of the working part of the spark plug in this mode of engine operation.

The working part of the candle is the elements located directly in the combustion chamber: the thermal cone of the insulator, the end face of the central electrode and the side electrode.

Thermal Insulator Cone (shed) - a part of the insulator located in the working chamber of the candle, perceiving with its surface the flow of heat from the flame and hot burnt gases.

The thermal characteristic of a candle is the dependence of the working temperature of a candle on the operating modes of the engine.

Spark plug base - a threaded part of the housing designed to install a spark plug in the engine and to connect the high voltage electrical circuit of the ignition system with «weight».

Shunting of the ignition system - a short circuit of the high-voltage circuit of the ignition system to - ground - with current leakage through soot on the surface of the thermal cone of the insulator and (or) across a conductive bridge in the spark gap.

Conductive (conductive) bridge - soot, partially or completely filling the spark gap, having conductivity and creating an electrical circuit that closes the insulated central electrode to ground.