Oil pressure regulation

In engines with a pressure lubrication system, the maximum pressure in the system is limited by a pressure relief valve. This valve (sometimes called pressure reducing valve) located at the outlet of the pump. Relief valve limits maximum system pressure by draining oil back to pump inlet (pic. 3.15). The maximum oil pressure is determined by the elasticity of the relief valve spring. Without a relief valve, the oil pressure will rise indefinitely as the engine speed increases. The maximum pressure is usually set at the level of the minimum allowable pressure, which ensures reliable lubrication of all engine components.

Engine lubrication requires three to six gallons of oil per minute (1 gallon (Amer.) equals = 3.78 l).

The oil pump is selected so that its capacity is sufficient to provide the necessary pressure at low engine speeds, but not too large, in order to avoid cavitation at high speeds. Cavitation occurs when the speed of oil pumping out by the pump becomes greater than the throughput of the suction pipe. When the pump does not have enough oil, it sucks in air and air pockets or voids appear in the oil flow. When the pump begins to suck in air or vapors, it goes into cavitation mode.

Pic. 3.15. Spring Relief Valves - Piston and Ball

Note. The purpose of the stamped cover, put on top of the sieve of the oil pump suction pipe, is to prevent cavitation. The oil is kept under the cap, which helps to prevent the danger of air being sucked in by the pump, especially during hard braking and acceleration of the car.

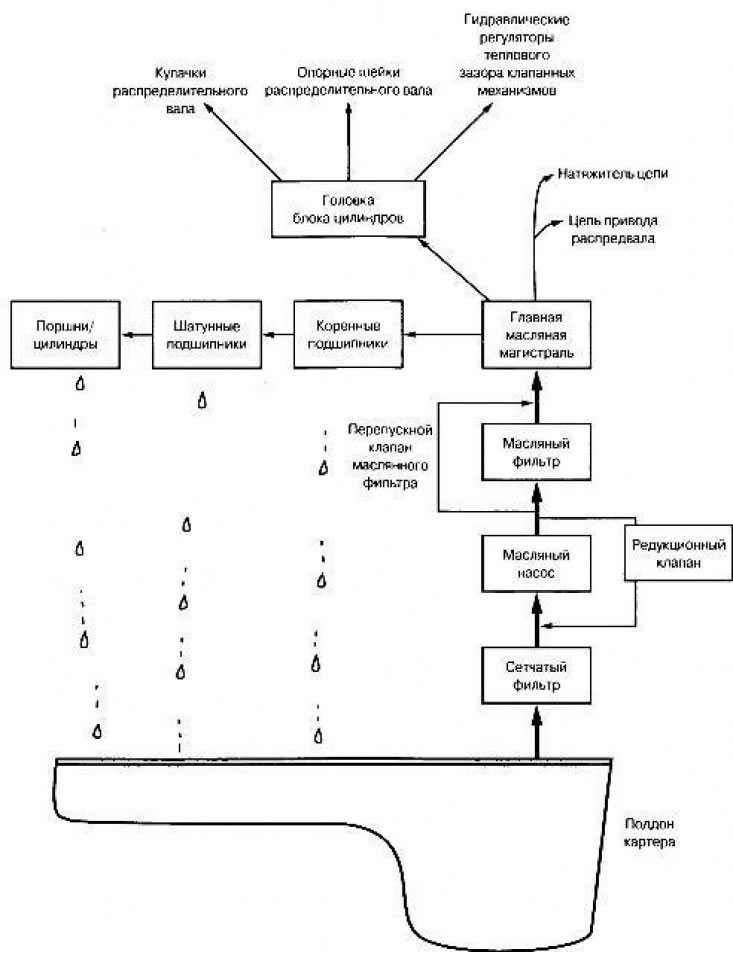

After leaving the pump, the oil is supplied to the moving parts through drilled oil lines (pic. 3.16). Once oil reaches the parts to be lubricated, pressure is no longer needed. Due to the effect of hydrodynamic lubrication between the surfaces of the parts, a lubricant film is formed and stably maintained. Extra power is used to create excess oil pressure, and the quality of lubrication is no better than at the minimum required pressure.

Factors affecting the oil pressure in the lubrication system

The oil in the lubrication system will be under pressure only if the oil pump output exceeds the oil flow through all "leaks" in the engine. Oil leakage occurs through gaps at the end points of the lubrication system. Endpoints are bearing clearances, rocker arms, splash holes in connecting rods, etc. These are specially provided gaps in the engine, necessary for its normal operation. As engine parts wear, the gaps increase and increase as a result of oil leakage.

The capacity of the oil pump must be large enough to supply oil to the lubrication system with a margin to cover its consumption through these leaks. The performance of an oil pump is determined by its size, rotational speed and condition. When the engine is idling, the pump rotates slowly and develops low efficiency.

If the oil flow through leaks exceeds the capacity of the oil pump, the oil pressure in the lubrication system is insufficient.

With an increase in engine speed, the performance of the oil pump increases and the increasing pressure in the lubrication system leads to an increase in oil consumption through leaks. As a result, the oil pressure increases until it reaches an adjustable maximum value.

Pic. 3.16. The oil flow enters the engine through the oil pump suction port and eventually flows back into the oil pan.

The viscosity of the engine oil affects both the performance of the oil pump and its flow through leaks. liquid oil (very low viscosity) easily slips past the pump teeth and flows easily through gaps. Hot oil has a lower viscosity, so the oil pressure in a warm engine is often low. Cold oil has a higher viscosity (density), than hotter. As a result, the oil pressure in a cold engine, even at idle, is higher. High oil pressure in a cold engine causes the pressure relief valve to open more in this case to release excess oil in excess of what is needed for a warm engine. The greater the oil pressure in the system, the more the pressure reducing valve spring is compressed and the greater the valve opening becomes.

The use of a higher viscosity oil in the engine causes the oil pressure in the cooling system to reach the reset valve threshold at a lower engine speed.