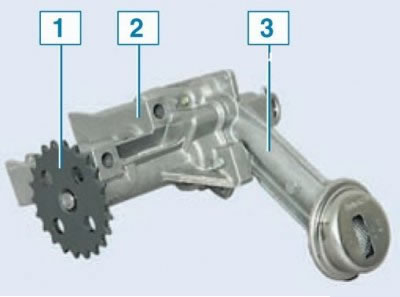

Oil pump Lada Largus: 1 - driven sprocket of the drive; 2 - pump housing; 3 - pump housing cover with oil receiver

Oil pump in the spare parts catalog - [16 cells] [8 cells].

The gear oil pump pressurizes the lubrication system. It is located in the front in the oil pan and is attached to the cylinder block and is driven by a chain drive from the crankshaft.

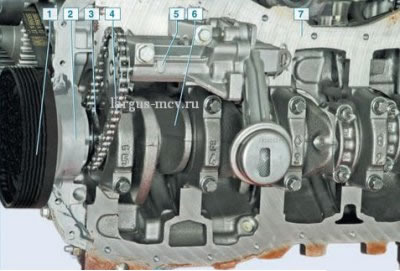

Oil pump drive (oil pan removed): 1 – a pulley of a drive of auxiliary units; 2 – a cover of the block of cylinders; 3 - drive sprocket of the pump drive; 4 - drive chain; 5 - oil pump; 6 - crankshaft; 7 - cylinder block

Removing the oil pump

The operation is not complicated and is carried out in a pit, or on a lift.

Remove the oil pan.

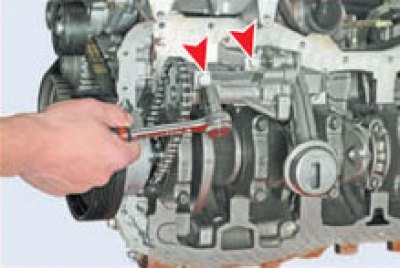

head «at 13» unscrew the two bolts securing the oil pump to the cylinder block (for clarity shown on the removed engine) …

... disengage the pump sprocket from the drive chain and remove the pump.

The principle of operation of oil pumps in vehicles with internal combustion engines

All serial automobile engines are equipped with a pressure lubrication system. The oil pressure in the system is maintained by the oil pump.

Pic. 3.9. In most engines, the oil pump is driven from the ignition distributor drive gear through the intermediate shaft

In most engines equipped with an ignition distributor, the driven gear of the distributor drive is engaged with the drive gear mounted on the camshaft, as shown in fig. 3.9. The oil pump is driven by an intermediate shaft, often hexagonal in shape, connected to the end of the ignition distributor drive shaft. In some engines, a short shaft is used to drive the ignition distributor and oil pump, the gear of which is engaged with the camshaft gear. In this case, the oil pump rotates at half the speed of the crankshaft. In other engines, the oil pump is driven directly from the crankshaft, through a mechanism similar to the automatic transmission pump drive mechanism - in this case, the oil pump rotates at the same speed as the crankshaft. An example of a crankshaft driven oil pump is shown in fig. 3.10-3.12.

Pic. 3.10. Oil pump mounted on the front cover of the engine. It is driven by a crankshaft

Pic. 3.11. Crankshaft driven rotary gear oil pump

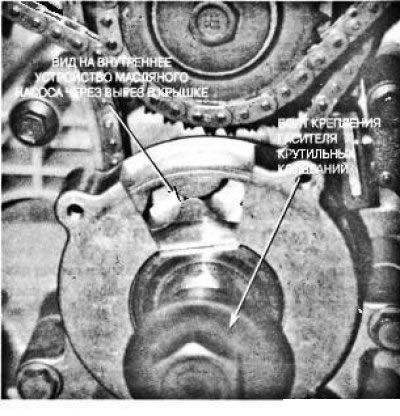

Pic. 3.12. Section through the oil pump installed in the eight-cylinder V-engine of a General Motors Northstar car. The vibration damper mounting bolt must be tightened with the required tightening torque, because it is due to the clamping force created by this bolt that the oil pump is ensured

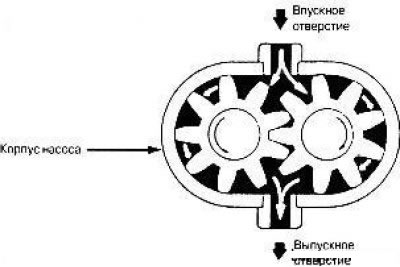

In automobile engines, as a rule, two types of pumps are used - gear and rotary (pic. 3.13). All oil pumps are positive displacement pumps - each revolution pumps the same amount of oil. Thus, all the oil entering the pump is displaced from it. The gear pump consists of two spur gears rotating in a tightly fitted housing. One of the gears is connected to the drive, while the other rotates freely. The teeth of the wheels, disengaging, diverge, capturing the oil flowing through the pump inlet. Oil is driven along the outer circle of the gear train - in the space between the walls of the housing and the teeth of the wheels, as shown in Fig. 3.14.

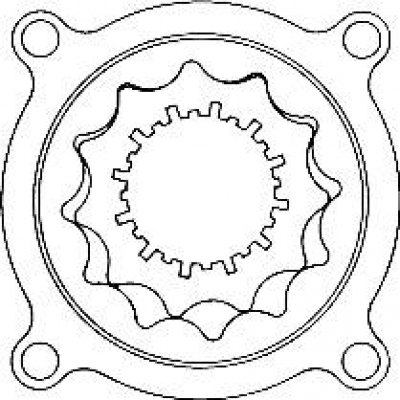

When the teeth re-engage, the trapped oil is squeezed out into the pump outlet, thus pressurizing the lubrication system. The rotary type oil pump consists of a special gear wheel with petal-shaped teeth, which is engaged with the inner surface of the rotor with petal-shaped recesses. The central gear is connected to the drive, and the rotor surrounding it rotates freely. When the petals move apart, the space between them is filled with oil - just like in a gear pump. When the pump rotates, the oil is transferred in a circle between the petals. As the petals approach, oil is forced out of the space between them under pressure, in the same way as in a gear pump. Pump parameters are selected in such a way that it maintains a pressure of at least 10 psi in the oil line of a warm engine, idling. inch (70 kPa). As the engine speed increases, the pressure will increase by about 10 psi. inch per thousand revolutions per minute as the speed of the motor-driven pump also increases.

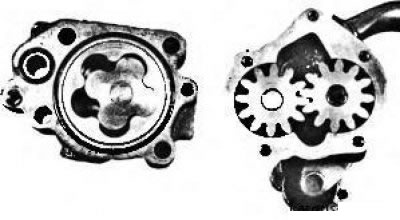

Pic. 3.13. Rotary type oil pump (tracheid design) (left) and gear type (on right)

Pic. 3.14. In a gear type oil pump, oil is pumped through the outer circle of the gear train. This is an example of a positive displacement pump, all the oil entering such a pump is displaced from it