Removing

Operations common to all vehicle configurations

Put the car on a two-post lift, apply the parking brake, turn off the ignition and disconnect the wire terminal "masses" from the battery.

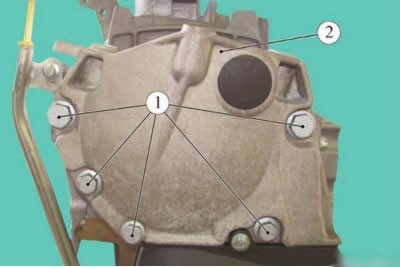

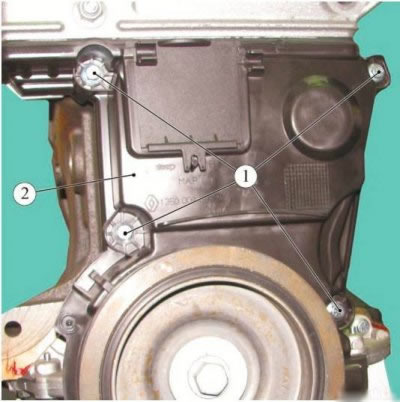

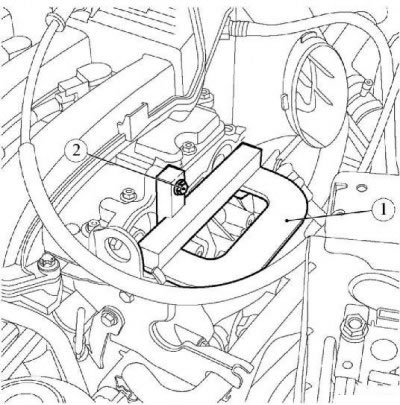

Figure 5-1 - Removing the plug of the hole for the TDC lock: 1 - hole plug for the TDC retainer

For vehicles with K4M engine additionally

Remove inlet pipe.

Remove intake silencer.

Operations common to all vehicle configurations

Remove the engine crankcase protection.

Remove the right front wheel.

Remove the right side mudguard.

Remove the accessory drive belt.

Remove the crankshaft pulley.

Remove the right engine mount.

Unscrew plug 1, Figure 5-1, holes for the TDC lock (interchangeable head Togh E14, extension, ratchet wrench).

For vehicles with K7M engine

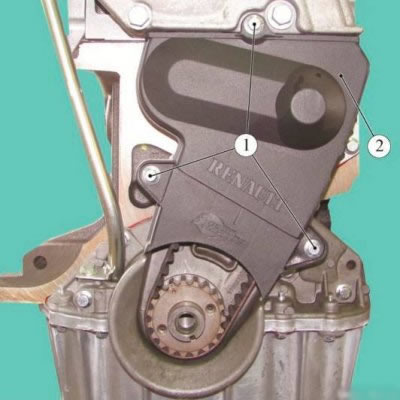

Remove bolts 1, Figure 5-2, fastening the upper timing cover (interchangeable heads 13, 16; ratchet wrench).

Figure 5-2 - Removing the top cover of the timing drive on the K7M engine: 1 - bolts for fastening the upper cover of the timing drive; 2 - the top cover of the timing drive

Remove top timing case 2.

Remove bolts 1, Figure 5-3, fastening the lower timing cover (interchangeable head 8, ratchet wrench).

Figure 5-3 - Removing the lower timing cover on the K7M engine: 1 - bolts for fastening the lower cover of the timing drive; 2 - lower timing cover

Remove lower timing cover 2.

Tighten the crankshaft pulley bolt with spacer (interchangeable head 18, knob).

Rotate the crankshaft clockwise so that the mark on the camshaft sprocket is one tooth away from the vertical axis of the toothed pulley and the mark on the crankshaft sprocket is one tooth away from the vertical axis of the pulley (interchangeable head 18, knob).

Install TDC lock (TDC lock Mot. 1489 or 67.7820-9701L).

Rotate the crankshaft clockwise until it stops (interchangeable head 18, knob).

Mark the lid with a marker (marker).

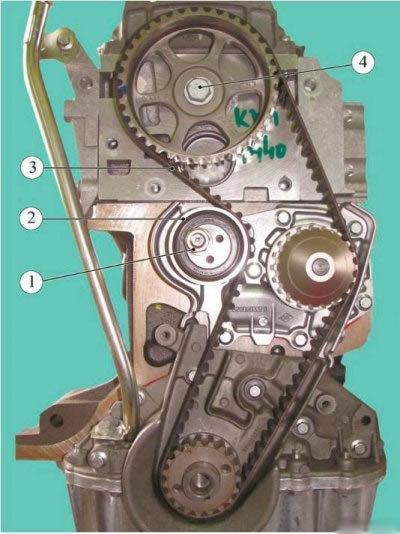

Loosen nut 1, Figure 5-4, fixing the tension roller axle (interchangeable head 16, ratchet wrench).

Figure 5-4 - Removing the timing belt on the K7M engine: 1 - nut for fastening the axis of the tension roller; 2 - tension roller; 3 - timing belt; 4 - a bolt of fastening of a pulley of a camshaft

Remove timing belt 3. Remove tension roller 2.

For vehicles with K4M engine

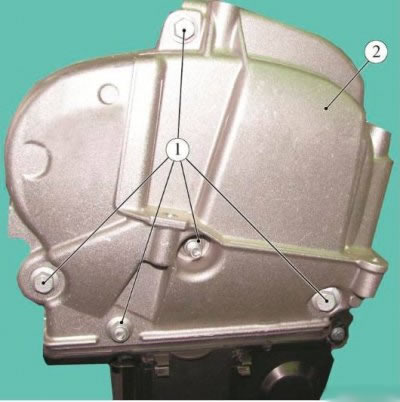

Loosen the bolts and nuts 1, Figure 5-5, fastening the upper timing cover (interchangeable heads 13, ratchet wrench).

Remove top timing case 2.

Unscrew the bolts 1, Figure 5-6, fastening the lower cover of the timing drive (interchangeable head 8, ratchet wrench).

Figure 5-5 - Removing the top cover of the timing drive on the K4M engine: 1 - bolts and nuts for fastening the upper cover of the timing drive; 2 - the top cover of the timing drive

Figure 5-6 - Removing the bottom cover of the timing drive on the K4M engine: 1 - bolts for fastening the lower cover of the timing drive; 2 - lower timing cover

Remove lower timing cover 2.

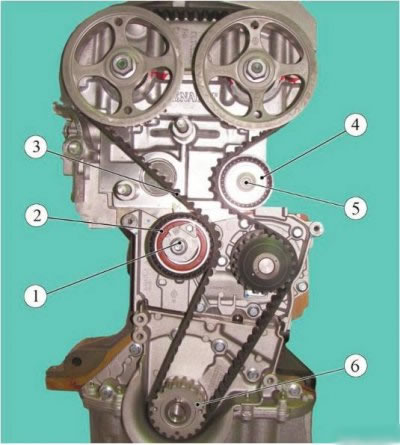

Loosen the tightening nut 1, Figure 5-7, fixing the tension roller axle (interchangeable head 16, ratchet wrench).

Loosen the bolt 5 fastening the bypass roller using the tool (tool Mot. 1368, interchangeable head Torx T50, ratchet wrench).

Remove pulley 4.

Remove timing belt 3.

Unscrew the nut 1 fastening the axis of the tension roller (interchangeable head 16, ratchet wrench).

Figure 5-7 - Removing the timing belt on the K4M engine: 1 - nut for fastening the axis of the tension roller; 2 - tension roller; 3 - timing belt; 4 - bypass roller; 5 - bypass roller fastening bolt; 6 - toothed pulley of the crankshaft

Remove tensioner pulley 2 for timing belt. Remove toothed pulley 6 of the crankshaft.

Installation

For vehicles with K7M engine

Attention. Parts that must be replaced:

- timing belt;

- timing belt tensioner;

- crankshaft pulley bolt.

Install without tightening the new tension roller 2, Figure 5-4 (interchangeable head 16, ratchet wrench).

Put a new timing belt 3 on the pulleys, aligning the marks on the belt with the marks on the toothed pulleys of the camshaft and crankshaft.

Timing belt installation procedure:

- crankshaft pulley;

- tension roller;

- camshaft pulley;

- water pump drive gear.

Timing belt tension on a K7M engine without an automatic tensioner

Install the tensioner pulley all the way into the timing belt.

Tighten the tension roller axle nut (interchangeable head 16, ratchet wrench).

Remove TDC retainer (TDC lock Mot. 1489 or 67.7820-9701L).

Install tool 1, Figure 5-8, to pretension the belt on the camshaft sprocket (tool Mot. 1501).

Figure 5-8 - Timing belt tension on the K7M engine: 1 - Tool Mot. 1501 timing belt pretensioner

Pre-tension the timing belt strands with a torque wrench. Torque applied 10 Nm (1.0 kgf·m) (torque wrench).

Remove tool from camshaft pulley (tool Mot. 1501).

Install the timing belt tensioner (tool Mot. 1135-01 or 67.7812-9703L).

Tension the timing belt by turning the tensioner pulley counterclockwise using the tool (attachment Mot.1135-01 or 67.7812-9703 L).

Adjust the tension of the timing belt by turning the tension roller using the tool (fixture Mot.1135-01 or 67.7812-9703 L; instrument Mot. 1505 or "LADAHOPMA - PINAR"). The measurement is carried out on the branch of the timing belt between the camshaft pulley and the water pump pulley. Oscillation frequency 160±10 Hz.

Tighten the tension roller nut. Tightening torque 50 Nm (5.0 kgf·m) (interchangeable head 16, torque wrench).

Rotate the crankshaft two turns clockwise (interchangeable head 18, ratchet wrench).

Lock the crankshaft in the TDC position with a lock (TDC lock Mot. 1489 or 67.7820-9701L).

Remove the TDC retainer.

Install the belt pretensioner onto the camshaft sprocket (tool Mot. 1501).

Pre-tension the timing belt strands with a torque wrench. Torque applied 10 Nm (1.0 kgf·m) (torque wrench).

Remove tool from camshaft pulley (tool Mot. 1501).

Check timing belt tension (instrument Mot. 1505 or "LADAHOPMA PINAR"). The measurement is carried out on the branch of the timing belt between the camshaft pulley and the water pump pulley. Oscillation frequency 160±10 Hz.

If the tension is out of tolerance, then repeat the procedure for adjusting the timing belt tension.

Apply FRENETANCHE to bolts 1, Figure 5-2, fastening the upper timing cover.

Install top timing cover 2 (interchangeable heads 13, 16; ratchet wrench).

Tightening torque for the upper timing cover bolts:

- bolts M10 - 44 Nm (4.4 kgf·m) (interchangeable head 16, torque wrench);

- bolts M8 - 22 Nm (2.2 kgf·m) (interchangeable head 13, torque wrench).

Install bottom cover 2, Figure 5-3, timing belt (interchangeable head 8, ratchet wrench).

Tightening torque of bolts 1 fastening the lower cover of the timing drive - 8 Nm (0.8 kgf·m) (interchangeable head 8, torque wrench).

Timing belt tension on a K7M engine with an automatic tension roller

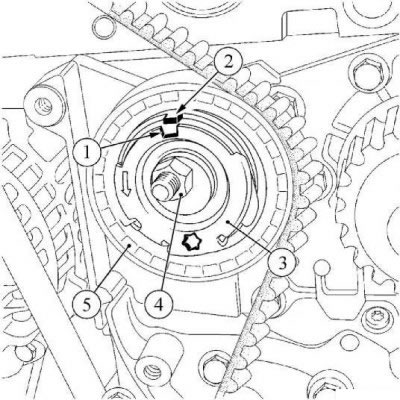

Install the movable indicator 1, Figure 5-9, after the fixed indicator 2 by turning the eccentric 3 counterclockwise using a Torx T50 wrench (interchangeable head Torx Т50, knob).

Tighten nut 4 for tensioning roller. The moment of an inhaling of a nut of fastening of a tension roller 25 Nm (2.5 kgf·m) (interchangeable head 16, torque wrench).

Remove TDC retainer (TDC lock Mot. 1489 or 67.7820-9701 L).

Rotate the crankshaft two turns clockwise (interchangeable head 18, ratchet wrench).

Install TDC lock (TDC lock Mot. 1489 or 67.7820-9701 L).

Turn the crankshaft clockwise until it stops at the TDC lock (interchangeable head 18, ratchet wrench).

Make sure that the movable pointer 1 is opposite the fixed pointer 2.

Figure 5-9 - Timing belt tension on a K7M engine with an automatic tensioner: 1 - movable pointer; 2 - fixed pointer; 3 - eccentric; 4 - nut for fastening the tension roller; 5 - automatic timing belt tensioner

- unscrew the nut securing the timing drive tensioner roller by no more than one turn, holding the eccentric with a wrench (interchangeable heads 16, Torx T50, knob - 2 pcs.);

- smoothly install the movable pointer after the fixed pointer by turning the eccentric counterclockwise using a Torx T50 wrench (interchangeable head Torx Т50, knob);

- tighten the nut of the tension roller. The moment of an inhaling of a nut of fastening of a tension roller 25 Nm (2.5 kgf·m) (interchangeable head 16, torque wrench).

Remove TDC retainer (TDC lock Mot. 1489 or 67.7820-9701L).

For vehicles with K4M engine

Attention. Parts that must be replaced:

- timing belt;

- tensioner pulley of the timing belt;

- bypass roller of the timing belt;

- crankshaft pulley bolt;

- intake camshaft plug;

- exhaust camshaft cover.

Attention. Before installing the crankshaft pulley, degrease the bearing surface of the pulley and the crankshaft toe.

If pointers don't match:

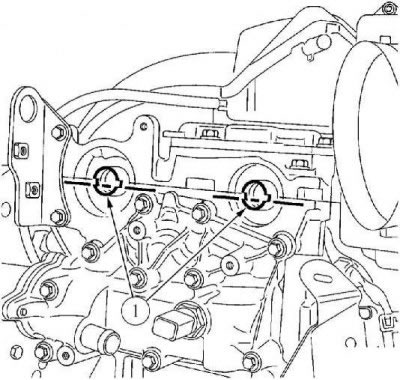

Position the grooves of the camshafts 1, Figure 5-10, horizontally and offset downwards from the axes of the shafts, if necessary turning the camshafts using the tool (tool Mot. 1496, interchangeable socket 16, extension, ratchet wrench).

Figure 5-10 - The position of the grooves of the camshafts at TDC: 1 - camshafts

Install tool 1, Figure 5-11, for setting the valve timing on the engine and secure with bolt 2 (tool Mot. 1496, interchangeable head 10, extension, crank).

Figure 5-11 - Installation of the device for setting the valve timing: 1 - Tool for setting the valve timing Mot. 1496; 2 - bolt

Align the marks on the camshaft pulley spokes vertically upwards.

Install a new tension roller 2, Figure 5-7, of the timing belt by inserting its protrusion into the groove.

Wrap, without tightening, the nut 1 fastening the axis of the tension roller (interchangeable head 16, ratchet wrench).

Install the crankshaft sprocket 6.

Install a new timing belt 3.

Install a new idler pulley 4 for the timing belt. Tightening torque of bolt 5 fastening the bypass roller of the timing belt - 50 Nm (5.0 kgf·m) (tool Mot. 1368, interchangeable head 16, ratchet wrench, torque wrench).

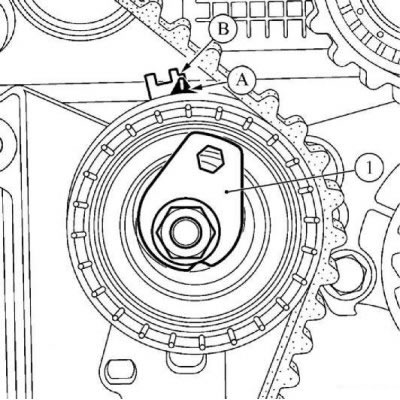

Using a 6 mm hexagon wrench, align the movable pointer A, Figure 5-12, with the notch B of the fixed pointer by turning the eccentric 1 clockwise.

Figure 5-12 - Setting the tension roller marks: 1 - eccentric; A - movable pointer; B - fixed pointer recess

Tighten the timing belt tensioner nut to 7 Nm (0.7 kgf·m) (interchangeable head 16, torque wrench).

Install the bottom cover 2, Figure 5-6, of the timing drive. The moment of an inhaling of bolts 1 fastenings of the bottom cover of a drive of GRM - 12 Nm (1.2 kgf·m) (interchangeable head 8, ratchet wrench, torque wrench).

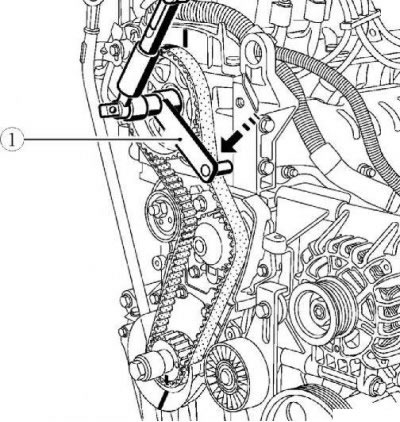

Figure 5-13 - Installing the TDC lock: 1 - TDC lock

Install retainer 1, Figure 5-13, TDC on the cylinder block (TDC lock Mot. 1489 or 67.7820-9701 L).

Install the crankshaft pulley.

Remove bolt 2, Figure 5-11, fastening tool Mot. 1496 and remove tool 1 for setting the valve timing (interchangeable head 10, extension, crank).

Remove the TDC retainer from the cylinder block (TDC lock Mot. 1489 or 67.7820-9701L).

Checking the tension of the timing belt on the K4M engine

Rotate the crankshaft two turns clockwise (when viewed from the timing side) and until the previously applied marks are combined (on the phase regulator pulley), install the TDC lock on the cylinder block.

Carefully drive the crankshaft up to the stop in the lock (interchangeable head 18, ratchet wrench).

Remove the TDC retainer from the cylinder block (TDC lock Mot. 1489 or 67.7820-9701L).

Verify that the movable pointer A, Figure 5-12, is positioned against the notch B of the fixed pointer, if not:

- Loosen nut 1, Figure 5-7, fastening the tension roller by no more than one turn, while holding the movable pointer with a 6 mm hex wrench (interchangeable head 16, ratchet wrench);

- smoothly bring the movable pointer to coincide with the notch by turning the eccentric clockwise.

Tighten the timing belt tensioner nut to 27 Nm (2.7 kgf·m) (interchangeable head 16, torque wrench).

Checking the installation of the valve timing on the K4M engine

Before checking the camshaft timing, make sure that the movable pointer A, Figure 5-12, the tension roller and the notch B of the fixed pointer are in the correct position.

Install retainer 1, Figure 5-13, TDC on the cylinder block (TDC lock Mot. 1489 or 67.7820-9701L).

Carefully drive the crankshaft up to the stop in the lock (interchangeable head 18, ratchet wrench).

Install (without making any effort) tool 1, figure 5-11, for setting the valve timing (the grooves at the ends of the camshafts 1, Figure 5-10, must be in a horizontal position and be shifted down from the axes of the shafts) (tool Mot. 1496).

If tool Mot. 1496 does not fall into place, then you need to re-install the valve timing and adjust the tension of the timing belt.

Remove tool Mot. 1496 for setting the valve timing.

Remove the TDC retainer from the cylinder block (TDC lock Mot. 1489 or 67.7820-9701L).

Install the window cover on the lower timing cover, making sure the pin fits into the notch.

Operations common to all vehicle configurations

Apply sealant to the threads of plug 1, Figure 5-1, the holes for the TDC retainer and tighten the plug. Plug tightening torque 20 Nm (2.0 kgf·m) (interchangeable head Torx E14, extension, ratchet wrench, torque wrench).

Install the right engine mount.

Install the crankshaft pulley.

Install the accessory drive belt.

Install the right side mudguard.

Install the right front wheel.

Install the engine crankcase protection.

For vehicles with K4M engine additionally

Install the inlet pipe.

Install the intake silencer.

Operations common to all vehicle configurations

Attach wire terminal "masses" to the battery.