This article is descriptive in nature and may be relevant for any brand of car.

To reduce the emission of nitrogen oxides (NOx) engines are equipped with exhaust gas recirculation valves - EGR valves (EGR — exhaust gas recirculation) (pic. 6.32). From 1973 until recently, EGR valves were used in almost all cars. In the latest engines, the high efficiency of computerized fuel injection systems allows compliance with the emission standards regulated by the standards of pollutants without the use of an exhaust gas recirculation system. In some engine designs, the interception of a certain part of the exhaust gases and their direction back into the cylinders is carried out by overlapping the intake and exhaust valves.

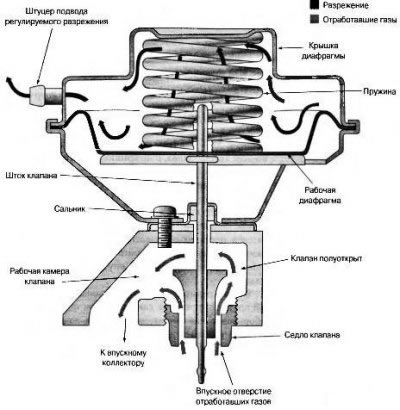

Pic. 6.32. Example of a typical pneumatically operated EGR valve

The operation of this valve is controlled by the on-board computer through the valve control solenoid, which is triggered by a pulse signal from the computer.

The EGR valve opens after the engine warms up, when the engine speed rises above idle speed. Through the open recirculation valve, from 5% to 10% of the exhaust gases are returned to the intake manifold, where they are mixed with the intake portion of the working mixture. As a result, the amount of fuel-air mixture entering the combustion chamber is reduced. Recirculated exhaust gases are inert (chemically passive) and do not enter into a combustion reaction. This leads to a decrease in the temperature in the combustion chamber, and as a result, to a decrease in the concentration of nitrogen oxides formed during the combustion of the working mixture.

The exhaust gas recirculation system provides means to ensure controlled connection of the intake and exhaust manifolds (pic. 6.33). The throughput of the connecting channels is controlled by the exhaust gas recirculation valve. In V-shaped engines, exhaust gases are taken into the recirculation system from the exhaust manifold transition. The exhaust manifold transition is connected by a channel provided in the engine casting to the exhaust gas recirculation valve. Through the recirculation valve, the exhaust gases are directed to the channels going to the intake manifold. In in-line engines, an external pipeline is usually used to supply exhaust gases to the recirculation valve. It is often made long enough to allow the gases to cool down on their way to the recirculation valve.

Pic. 6.33. When the recirculation valve is open, the exhaust gases pass through it into the channels leading to the intake manifold

Recirculation valves with low and high exhaust pressure converters

Many recirculation valve designs use a small internal valve which, by relieving the vacuum applied to the valve, prevents the valve from opening. In such cases, the EGR valve opens only when the pressure in the exhaust system rises. A valve of this design is called a recirculation valve with a high pressure converter. At low engine speeds and light engine load, the EGR system is not necessary and the back pressure is also low. Until the pressure in the exhaust system becomes high enough, the recirculation valve remains closed, even if it is under vacuum.

In each exhaust stroke, a portion of exhaust gases is ejected from the engine, accompanied by an increase in pressure in the exhaust manifold. The zone of high pressure is followed by a small zone of low pressure. A number of valve designs respond to this reduced pressure, which closes a small internal valve, allowing the recirculation valve to open due to the vacuum created above its diaphragm. This type of recirculation valve is called a low pressure converter recirculation valve. The following conditions must be met for the valve to work:

1. A vacuum must be created in the EGR valve itself. In older, carbureted engines and some engine designs with a throttle chamber central injection system, this reduced pressure is usually created by vacuum in the intake manifold and controlled by the on-board computer using a solenoid valve.

2. The valve must be subjected to exhaust gas backpressure sufficient to close the internal valve installed in the recirculation valve and thus allow the valve diaphragm to move under the vacuum maintained in the recirculation valve.

Electronic exhaust gas recirculation system

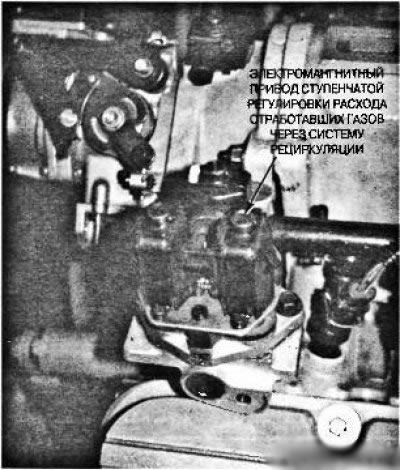

Since the mid-1990s, many engines have used solenoid valves or stepper motors to control the flow of exhaust gases from the exhaust manifold to the intake manifold (called linear motors). On fig. Figure 6.34 shows an example of a recirculation system assembly that has three solenoid valves - this assembly is used in a General Motors six-cylinder V-engine. The on-board computer controls all three solenoid valves and can turn on one or two of them, or all three at the same time, accurately dosing the required amount of exhaust gases sent to the intake manifold. Many motors use an in-line recirculation valve controlled by a stepper motor. The stepwise adjustment of this valve on the signal of the on-board computer provides an accurate dosage of the flow of exhaust gases in any mode of engine operation. The feedback circuit allows the computer to fine-tune the position of the valve and generates an error code if the actual position of the valve is outside the allowable range of controlled positions. You can check how the recirculation valve works using the program for testing it provided in the computer.

Pic. 6.34. The recirculation actuator used in this General Motors 3800cc six-cylinder V-twin engine. see, three solenoid valves are used. The test program can turn on each of the solenoids individually to check the function of the valve and whether there is enough capacity in the exhaust manifold passages to pass enough exhaust gases to have an effect on the engine's performance when the system is cycling

Experience exchange

The owner of a Chevrolet Blazer equipped with a 4.3L V6 engine complained that the engine "pulls" and is unstable. It seems that. everything worked fine, except for one thing: the service technician discovered that at idle a slight vacuum was created in the EGR valve. The vehicle was equipped with a solenoid operated recirculation valve, the so-called electronic vacuum control valve (EVRV — electronic vacuum regulator valve) General Motors Corporation. A solenoid valve controlled by the on-board computer regulates the vacuum created in the recirculation valve, which controls its operation. The technician, using the service manual, understood in detail the features of the recirculation system and found out that the vacuum in the recirculation valve should only be created when the speed selector is in one of the working gears (drive, low, reverse). Since the technician found vacuum with the transmission disengaged, this was apparently caused by a solenoid valve leak. After replacing the solenoid valve, the disturbances in the operation of the engine disappeared.

Note. The technician also learned from the service manual that the EGR system test should not be performed with a forced exhaust gas system connected to the engine exhaust pipe, since the vacuum created by this ventilation system can lead to false operation of the EGR valve.

I just wanted to help!

It was at the end of the working week. An experienced auto mechanic determined that the failure of the Buick's six-cylinder V-twin engine was caused by a worn EGR valve. When reduced pressure was created in the valve, it remained completely immobile. When the degree of vacuum was increased using a manual vacuum pump, the valve opened and remained in this position all the time. A new valve of the same type could only be received on Monday, but the owner wanted to pick up his car the same day to drive it at the weekend.

In order to somehow get the engine to work more or less normally, the technician deformed the top valve cover with a hammer to limit the travel of the recirculation valve stem. He warned the customer to be sure to return the car on Monday for a valve replacement. The client, of course, returned on Monday, but not alone, but with his lawyer. As it turned out, one of the pistons of the engine was broken. The lawyer reminded the technician and the service station manager that the emission control device was "modified". As a result, the company paid for the replacement of the engine with a new one, and the technician learned the lesson that it is always necessary to repair the car properly or not at all.