Note: If the clutch fails, we recommend replacing all its elements at the same time (driven and driven discs, clutch release bearing), since the work of replacing the clutch is laborious, and the life of undamaged clutch elements has already been reduced, therefore, if they are installed again, it may be necessary to replace the clutch again after a relatively small mileage.

Part numbers are listed Here (8 cells) and Here (16 cells).

Clutch device see here.

Work on the K4M and K7M engines to replace the clutch does not differ.

To work, you will need a mandrel to center the clutch disc.

Suitable mandrel from VAZ cars. (Original - Emb. 1518 or Emb. 1780, or 67.7823-9702 L)

Removing

Place the vehicle on a two-post lift, brake with the parking brake, turn off the ignition, open the hood and disconnect the wire terminal "masses" from the battery.

Remove gearbox (see here).

Note. When replacing the clutch, you can not completely remove the gearbox, but only move it away from the engine to the required distance. This work is shown Here.

Tip: If you install the old pressure plate, mark in any way (e.g. marker) the relative position of the disc housing and the flywheel to set the pressure plate in its original position (to maintain balance).

If equipped, install a flywheel retainer on the engine block (flywheel retainer Mot. 582-01).

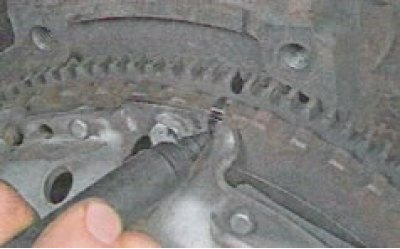

If not, then use a screwdriver or a mounting spatula to keep the flywheel from turning and...

... unscrew six bolts 1, figure 3-1, fastening the clutch pressure plate to the flywheel and remove the pressure plate 2 and clutch disc (interchangeable head 13, extension, crank).

Loosen the tightening of the bolts evenly: each bolt one turn of the wrench, moving from bolt to bolt in diameter.

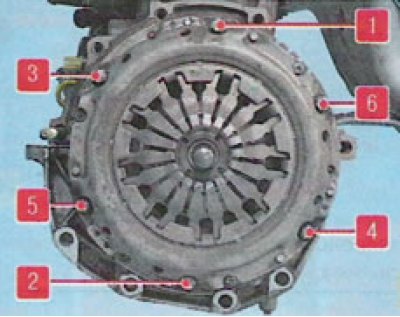

Figure 3-1 - Removing the clutch: 1 - pressure plate fastening bolt; 2 - clutch pressure plate

Remove the clutch pressure and driven discs from the flywheel while holding the driven disc.

Clutch control

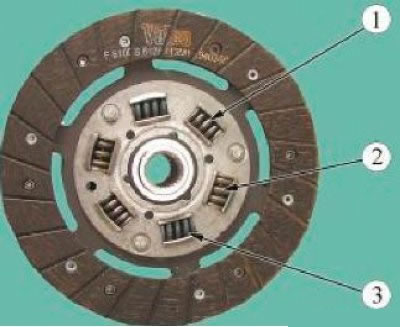

Clutch driven discs for vehicles with K4M and K7M engines have different damper spring stiffness. To distinguish the clutch discs, the damper springs are marked with paint, Figure 3-2.

Differences of driven clutch discs:

| Parameters | K4M engine | K7M engine |

| Outer diameter of the driven disk, mm | 200 | 200 |

| Thickness of a conducted disk, mm | 7,5 | 7,6 |

| Number of splines | 26 | 26 |

| Spring label color (figure 3-2) | 1 - gray; 2 - green; 3 - blue-lilac | grey |

Inspect clutch disc.

Figure 3-2 - Marks of the clutch disc on a car with a K4M engine: 1 - gray; 2 - green; 3 - blue-lilac

In the presence of cracks, dents, breakage of damper springs and cracks or delaminations of friction linings, the disc must be replaced.

Figure 3-3 - Clutch pressure plate

Preparing for installation

Check the surface of the engine flywheel in contact with the clutch disc. The surface of the flywheel must be free of scratches and tarnish marks.

Check that the engine crankshaft main bearing is not jammed.

Check the tightness of the oil seals of the engine and gearbox, replace if necessary.

Check the free movement of the clutch disc on the input shaft.

Check for signs of wear on the clutch engagement bearing guide bush and clutch fork.

Clean and flush the surface of the flywheel in contact with the clutch disc, the splines of the input shaft of the gearbox and the splines in the hub of the driven disc (white spirit, consumption rate 10 g).

Installation

Before installation, check the ease of movement of the driven disk along the splines of the gearbox input shaft, apply refractory grease to the splines of the driven disk hub.

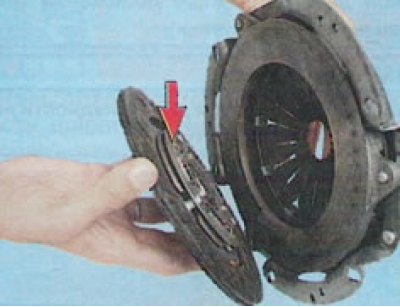

Note. Install the driven disc so that the protruding part of the disc hub (shown by arrow) was directed towards the diaphragm spring of the clutch cover.

Install the clutch assembly on the flywheel without tightening the bolts 1, Figure 3-1, pressure plate mountings (interchangeable head 8, knob and extension).

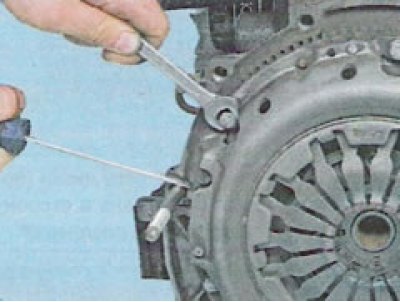

Install mandrel 1 in the hub of the driven disk, Figure 3-4, and center the clutch driven disk relative to the flywheel.

Figure 3-4 - Centering the clutch disc: 1 - mandrel for centering the clutch disc

Tighten bolts 1, Figure 3-1, fastening the clutch pressure plate in a crosswise pattern. (interchangeable head 13, extension, knob, torque wrench):

Clutch bolt tightening sequence

The moment of an inhaling of bolts of fastening of a pressure plate of coupling 20 Nm (2.0 kgf·m).

Remove flywheel retainer (if it was).

Install gearbox.

After installing the gearbox, check the travel of the clutch release fork (for vehicles with cable drive) and lack of air in the hydraulic clutch (for vehicles with hydraulic drive).

If necessary, adjust the travel of the clutch release fork (for vehicles with cable drive) or bleed air from clutch hydraulic system (for vehicles with hydraulic drive (JR5)).