Cable clutch (for JH3 gearbox)

The clutch cable drive does not have an automatic clearance compensation mechanism.

Single disc, dry, with a central diaphragm spring. The mechanism is located in an aluminum crankcase, structurally integrated with the gearbox and attached to the engine block.

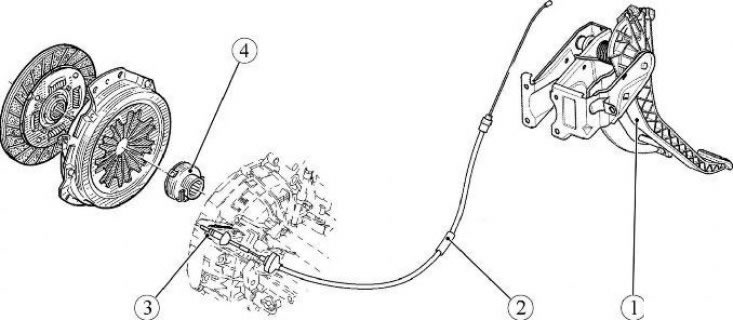

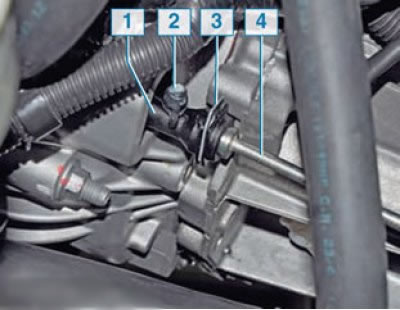

1 - clutch pedal; 2 - clutch cable; 3 - clutch release fork; 4 - clutch release bearing

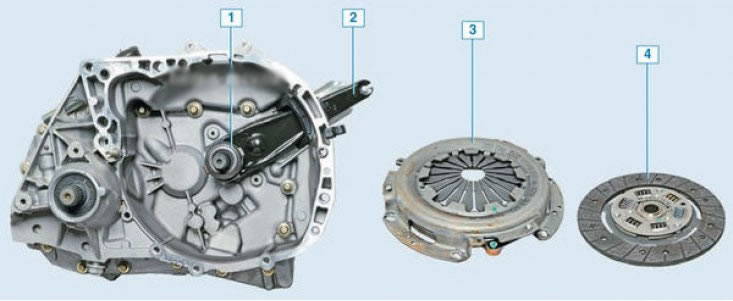

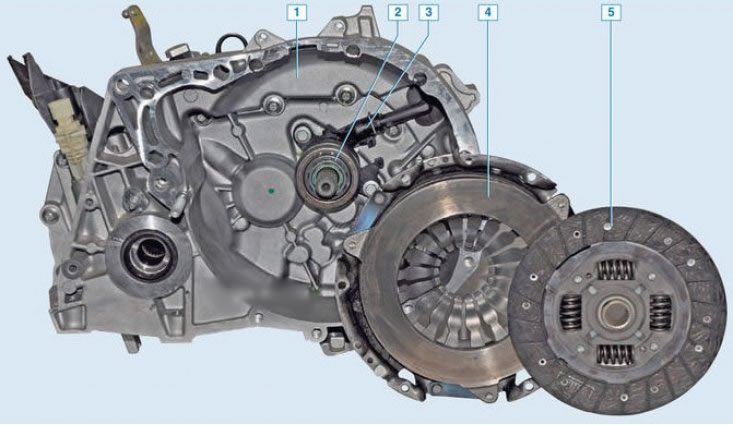

1 - clutch release bearing with clutch assembly; 2 - clutch release fork; 3 - pressure plate with casing assembly («clutch basket»); 4 - driven disk

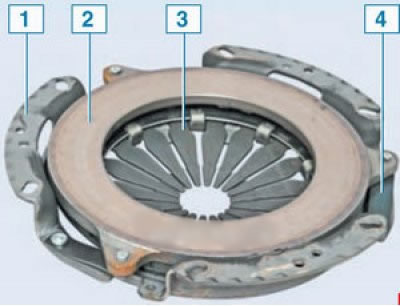

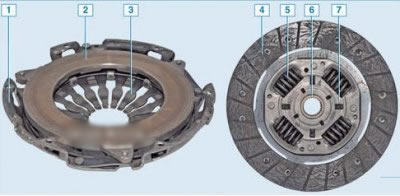

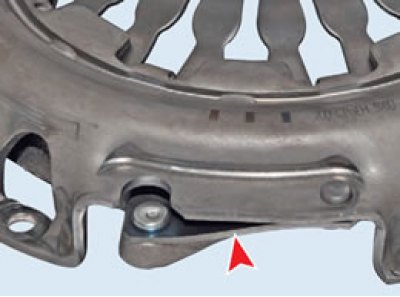

clutch basket (pressure plate assembly): 1 - clutch cover; 2 - pressure plate; 3 - diaphragm spring; 4 - connecting plates

The clutch cover is connected with six bolts to the engine flywheel. Replacement «baskets» necessary in case of annular wear of the petals of the diaphragm spring to a depth of more than 0.8 mm, as well as in the event of a decrease in the effort on the pedals when the clutch is disengaged (and, accordingly, an increase in the working stroke), which indicates a large wear on the surface of the pressure plate or «draft» diaphragm spring.

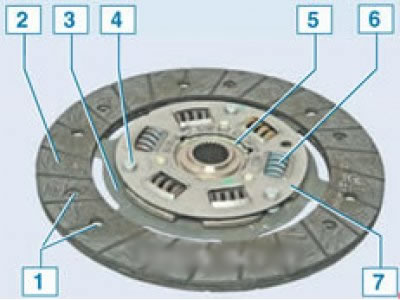

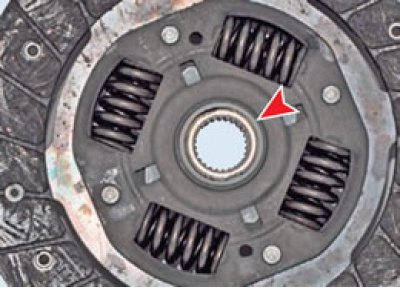

Driven clutch disc: 1 - friction lining rivet; 2 - friction linings; 3 - spring plate; 4 - support pin; 5 – disk hub; 6 - damper spring; 7 - damper plate

The driven disk with a spring damper of torsional vibrations is mounted on the splines of the input shaft of the gearbox between the flywheel and the pressure plate.

Outer diameter 200 mm, thickness 7.6 mm. The driven disk is replaced if its axial runout in the area of the friction linings is more than 0.5 mm, oiling, cracking, scuffing or uneven wear of the linings, weakening of the rivet joints, and also if the heads of the rivets are deepened from the surface of the linings by less than 0.2 mm.

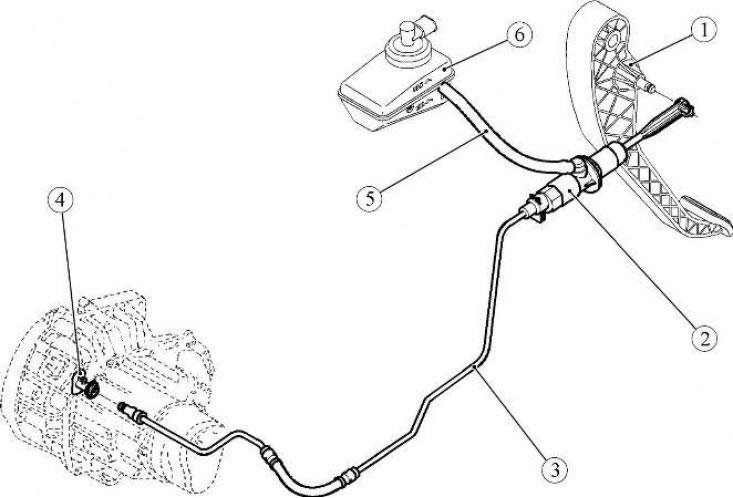

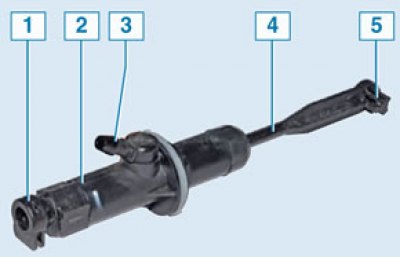

Clutch cable: 1 - front tip of the cable; 2 - front tip of the cable sheath; 3 - rear tip of the cable; 4 - rear tip of the cable sheath; 5 - cable; 6 - rubber support sleeve

The front end of the cable is attached to the clutch release fork, and the rear end is attached to the clutch pedal holder. The front tip is threaded, used to adjust the clutch release drive.

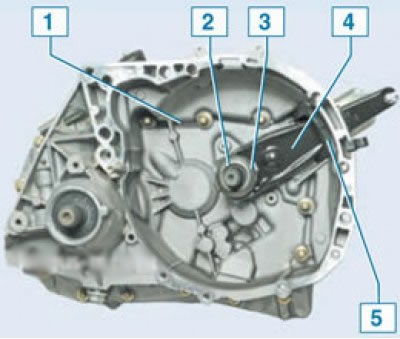

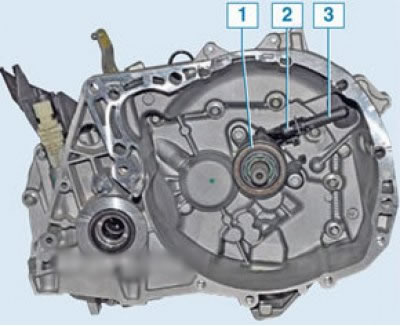

Clutch Drive Details: 1 - clutch housing; 2 – the directing plug of the bearing of deenergizing of coupling; 3 - clutch release bearing with clutch assembly; 4 - clutch release fork; 5 - dirt cover

Hydraulic clutch (for JR5 gearbox)

The clutch release drive is hydraulic. The force in it from the clutch pedal to the clutch release bearing is transmitted through the working fluid. The hydraulic drive consists of the main and working clutch cylinders connected by a pipeline. The working fluid is filled into the tank, which is installed on the main brake cylinder and is used to power the brake system and drive the clutch.

1 - clutch pedal; 2 - the main cylinder of the clutch drive; 3 - pipeline connecting the main and working cylinders of the clutch drive; 4 - working cylinder of the clutch drive; 5 - inlet pipeline of the main cylinder of the clutch drive; 6 - a reservoir of a hydraulic drive of brakes

1 - clutch housing; 2 - clutch release bearing; 3 – the working cylinder of deenergizing of coupling; 4 - pressure plate with casing assembly («basket»); 5 - driven disk

«Basket» and clutch disc: 1 - casing; 2 - pressure plate; 3 - diaphragm spring; 4 - friction linings; 5 - damper springs; 6 – a nave of a conducted disk; 7 - damper

Elastic plates. A diaphragm spring is installed in the casing, which is stamped from sheet spring steel. In the free state, the spring has the form of a truncated cone with radial slots extending from the inner edge of the spring. The slots of the spring form eighteen petals, which are elastic release levers. Due to the elasticity of the levers, the diaphragm spring creates a more even pressure on the clutch pressure plate, which contributes to smoother engagement and disengagement of the clutch.

The location of the wavy spring plate. The driven disk with a spring damper of torsional vibrations is installed on the splines of the input shaft of the gearbox between the engine flywheel and the pressure plate.

The vibration damper dampens vibrations resulting from dynamic loads in the transmission and uneven engine operation.

Idling damper. A disk hub is installed between the damper plates. Damper springs are installed in the grooves of the hub and damper plates. The damper plates are connected by bearing pins. There are cutouts in the disc hub opposite the support posts that allow the hub to rotate within certain limits relative to the damper plates, while compressing the damper springs. This allows you to reduce dynamic loads in the transmission when starting the car and shifting gears.

Clutch Release Bearing: 1 - bearing; 2 – working cylinder; 3 - tube for supplying fluid to the working cylinder

Details of the working cylinder and clutch release bearing: 1 - clutch release bearing; 2 - protective cover; 3 – working cylinder; 4 - retainer; 5 - tube for supplying fluid to the working cylinder

Clutch Master Cylinder: 1 - fitting for connecting the hydraulic drive tube; 2 - the body of the main cylinder; 3 - fitting for connecting the hose for supplying liquid from the tank; 4 - pusher; 5 - pusher tip

Clutch bleed valve: 1 - tube for supplying fluid to the working cylinder; 2 - bleed valve; 3 - retainer; 4 – a tube of a hydrodrive of coupling

To pump the clutch hydraulic drive, a fitting is located on the plastic tube for supplying fluid to the working cylinder, closed with a rubber cap.