When replacing clutch parts, you can not completely remove the gearbox (since for this you need to remove the subframe, which is very time consuming), but only move it away from the engine to the required distance.

Disconnect the clamp from «minus» battery.

Removing the left wheel drive (see here).

We unscrew the bolt securing the left subframe bracket to the body and loosen the nut that secures the bracket to the suspension arm (see here).

Disconnect the clutch cable from the clutch fork and bracket on the gearbox (see here).

Disconnect the gearshift control rod from the gearshift switch (see here).

Remove the speed sensor.

Remove the crankshaft position sensor.

Disconnect the wiring connector from the reverse light switch.

Disconnect the ECM wiring connector from the control oxygen sensor wiring harness.

Remove the sensor block from the holder on the gearbox and remove the wiring harness from the holder.

We remove the starter (see here).

Open the holder on the gearbox housing and remove the wiring harness from it. We unscrew the four bolts securing the engine crankcase to the gearbox (see here).

We substitute adjustable stops under the engine and gearbox. Remove the rear and left supports of the power unit (see here and here).

Disconnecting the wires "masses" from the gearbox, unscrew the bolts and nuts securing the gearbox to the cylinder block (see here).

While holding the inner joint housing of the right wheel drive...

... we take the gearbox away from the engine, removing the input shaft from the hub of the clutch disc.

In this case, the splined shaft of the side gear of the differential will come out of the tip of the housing of the inner hinge of the right wheel drive.

We take the gearbox away from the engine to the desired distance and rest the left side of the box on the subframe.

When removing and installing the gearbox, the gearbox input shaft must not be supported on the petals of the diaphragm spring, so as not to damage them.

To replace the clutch release bearing, move it along the guide sleeve to the end of the gearbox input shaft, disengaging the clutch release fork tabs from the bearing clutch.

Removing the bearing (for clarity shown on the removed gearbox).

We remove the fork from the ball joint and remove the end of the fork from the dirt cover.

Before installing the bearing, apply grease to the surface of the guide sleeve, clutch release fork legs, and also to the fork ball joint. We replace the torn rubber boot of the clutch release fork with a new one.

Install the clutch release bearing in reverse order.

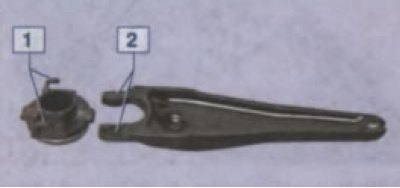

When installing the foot bearing, 2 forks must enter the plastic hooks 1 of the bearing sleeve.

Further, the operations for replacing the clutch discs are similar to replacing them with the gearbox removed (see here).