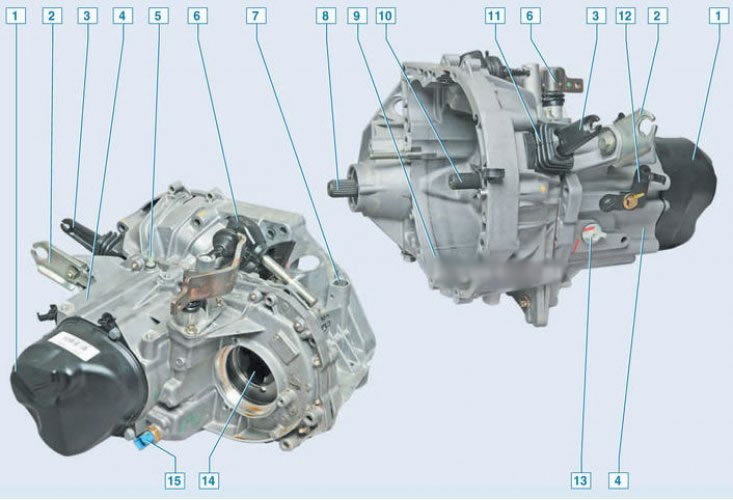

JH3 gearbox

Gearbox JH3: 1 - rear cover of the gearbox; 2 - clutch cable bracket; 3 - clutch fork; 4 - gearbox housing; 5 - breather fitting; 6 - gear shift mechanism; 7 - cavity for the speed sensor; 8 - shaft of the right side gear of the differential; 9 - clutch housing; 10 - input shaft; 11 - anther; 12 - holder for electrical wires; 13 - oil filler cap; 14 - body of the inner hinge of the drive mechanism of the left wheel; 15 - reverse light switch

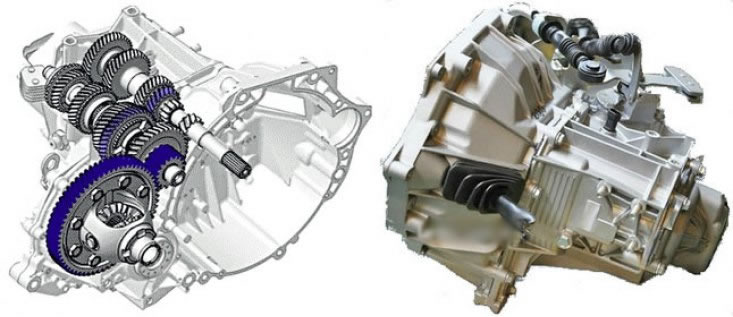

The car engine, like all internal combustion engines, develops power and torque in a relatively narrow rev range. As the engine speed decreases, the power decreases.

The power train allows you to reduce the number of revolutions of the drive axle in relation to the number of revolutions of the engine crankshaft, increasing tractive effort. The higher the traction force, the lower the speed.

When driving a car, it becomes necessary to apply different speeds and different traction forces. So, for example, when driving on deep sand, the speed is negligible, and to overcome the resistance of the road, a rather large traction force is needed. High tractive effort is also required when starting the vehicle and overcoming steep inclines. On the contrary, when driving on a paved road, little tractive effort is needed, and the driving speed can be high.

To increase or decrease the traction force on the drive axle with a constant torque on the engine shaft, a gearbox is used in the vehicle's power transmission.

Due to the fact that the engines of different car models have different power, then, of course, the gear ratios of individual gears, and, consequently, the number of teeth of the gears are different. However, the principle of operation of gearboxes is the same, and the operations for disassembly, assembly and repair are generally similar.

The purpose of the gearbox is to provide further transformation of torque in magnitude and direction in accordance with the load on the car, as well as to allow the engine to idle.

The basic principle of operation of the gearbox is the same everywhere, the essence of which is the pairwise connection of gears that have a different number of teeth. In this case, the torque transmitted by the gears changes in proportion to the gear ratio, i.e. the ratio of the net teeth of the driven gear to the number of teeth of the drive gear.

The gearbox is, in principle, a very simple device.

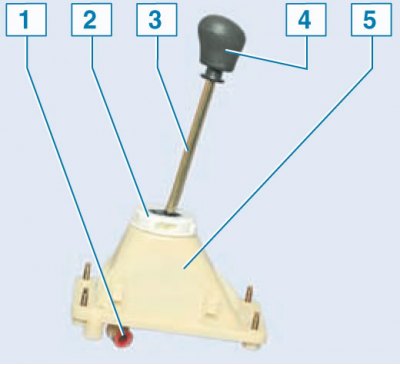

Gearbox control mechanism: 1 - sleeve (the gearbox control rod is connected to it); 2 – a lock of the gearshift lever; 3 - gearshift lever (has a ball joint that is inserted into the housing); 4 - lever handle; 5 - plastic case

Gearbox control rod: 1 - coupling bolt; 2 - clamp; 3 - nut; 4 - thrust; 5 - thrust finger

The rod is attached at one end to the bushing of the gearbox control mechanism, and at the other end to the shift mechanism installed on the gearbox.

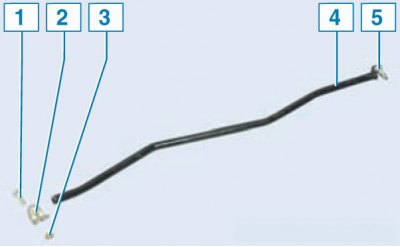

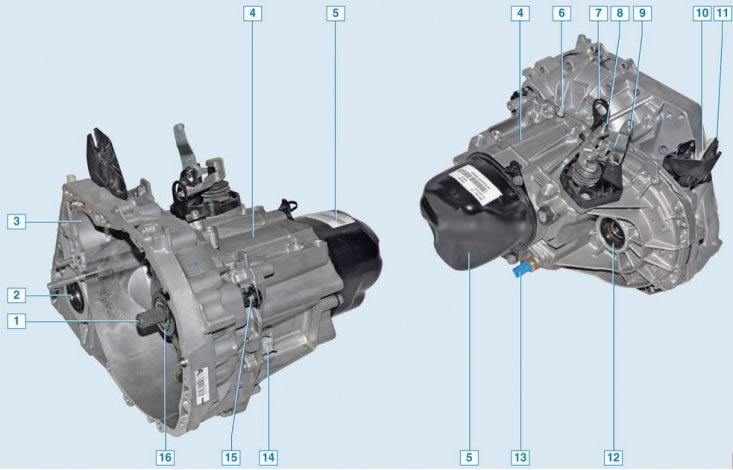

Gearbox JR5

Gearbox JR5: 1 - input shaft; 2 - right wheel drive oil seal; 3 - clutch housing; 4 - gearbox housing; 5 - back cover; 6 - breather fitting; 7 - eye-bracket; 8 - gear shift lever; 9 - gear selection lever; 10 - speed sensor or plug; 11 - bracket for fastening transmission control cables; 12 - left wheel drive oil seal; 13 - reverse light switch; 14 - oil filler cap; 15 - tube for supplying fluid to the working cylinder of the hydraulic clutch; 16 - clutch release bearing

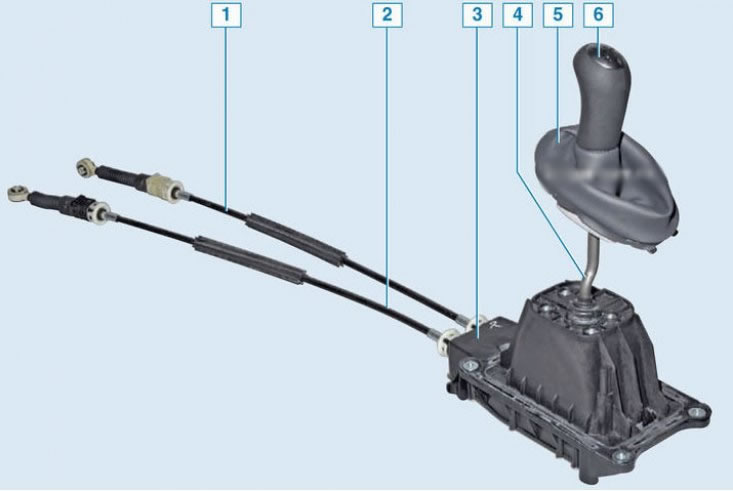

Gearbox control mechanism: 1 - gear selection cable; 2 - gear shift cable; 3 - control mechanism; 4 - gear lever; 5 - a cover of the gear lever; 6 - gear lever handle

Checkpoint VAZ-21809

Redesigned gearbox manufactured by VAZ with a cable shift drive. It has been installed on Lada Largus instead of the JR5 gearbox since 2018, paired with a 16-valve VAZ-21129 engine. Together with foreign engineers, a number of improvements were made on the box in order to reduce vibration noise, incl. gear tooth profile has been changed. Improved clarity and balance of gear shifting.

Gear ratio tables for LADA Largus gearbox

Note. gear ratios on vehicles with AvtoVAZ engines differ from those presented.

| 5 places with K7M | 7 seats with K7M | 5 and 7 seats with K4M | Van with K7M and K4M | |

| Transmission | JH3 540 | JR5 551 | JR5 549 | JR5 517 |

| 1st gear | 3,727 | 3,727 | 3,727 | 3,727 |

| 2nd gear | 2,048 | 2,048 | 2,048 | 2,048 |

| Gia transfer | 1,393 | 1,321 | 1,393 | 1,321 |

| 4th gear | 1,029 | 0,971 | 1,097 | 0,971 |

| baya transfer | 0,82 | 0,795 | 0,892 | 0,738 |

| Reverse gear | 3,545 | 3,545 | 3,545 | 3,545 |

| Main couple | 4,214 | 4,5 | 4,214 | 4,928 |

Gear ratios of the gearbox VAZ-21809

| l | 3,636 |

| II | 1,952 |

| III | 1,357 |

| IV | 0,941 |

| V | 0,784 |

| Reverse | 3,500 |

| Final drive | 3,944 |

Factory designations and fifth gear parameters

| Gear ratio | Input shaft gear | Output shaft gear | ||

| Number of teeth | Part number | Number of teeth | Part number | |

| 0,892 | 37 | 8200611295 | 33 | 8200608035 |

| 0,820 | 39 | 8200611299 | 32 | 8200607980 |

| 0,795 | 39 | 8200611297 | 31 | 8200607978 |

| 0,756 | 41 | 8200611301 | 31 | 8200607981 |

| 0,738 | 42 | 8200611303 | 31 | 8200607983 |

Mass of gearboxes (gearbox weight in kilograms)

- JH3 - 33.0 kg

- JR5 - 34.0 kg

- 21809 - 31.8 kg

Checkpoint identification

Determining the installed gearbox by configuration and engine (only for motor Renault).

| Body and engine | station wagon 5 places with K7M | station wagon 7 seats with K7M | station wagon 5 and 7 seats with K4M | Van with K7M and K4M |

| Installed checkpoint | JH3 540 | JR5 551 | JR5 549 | JR5 517 |

In more detail, the ratio of engines and gearboxes is indicated Here.

Note. To accurately identify the installed gearbox, see its marking (see below).

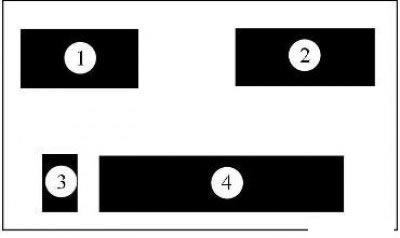

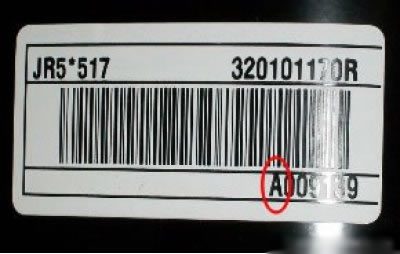

Plate 1, Figure 2-1, punched into the gearbox housing, provides information about the gearbox, Figure 2-2.

Figure 2-1 - Location of the identification plate on the gearbox: 1 - identification plate

Figure 2-2 - Location of information fields on the gearbox plate: 1 - type of gearbox; 2 - gearbox index; 3 - manufacturer; 4 - factory number

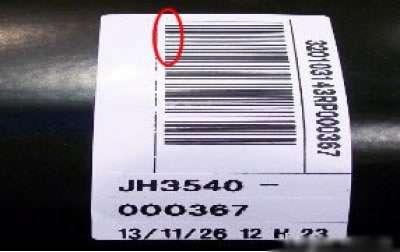

The markings on the gearboxes are applied from below, on the crankcase.

The gearbox code is located on a sticker on the back of the black gearbox cover (on the left in the direction of travel). Although it is difficult to see her on a car, you can:

Differences in the designation of the KP

Production AVTOVAZ

Marking of JH3 and JR5 units of AVTOVAZ assembly with a letter "R"

External supply

Marking of units JH3 and JR5 external supply (e.g. "A")