Signs of air ingress into the hydraulic brake system:

- when pressing the pedal once - increased pedal travel, its «softness»;

- when repeatedly pressing the pedal - a gradual decrease in the pedal travel with a simultaneous increase in its «rigidity».

Before pumping the hydraulic drive, it is necessary to find and eliminate the cause of depressurization.

Note. If the pumping of the hydraulic drive is associated with the repair of any one circuit and the serviceability of the other circuit is known, then only the repaired circuit can be pumped.

The sequence of pumping the brake mechanisms:

- rear right;

- front left;

- rear left;

- front right.

You will need: key «for 8», rubber hose, container for collecting brake fluid.

1. Check the level and, if necessary, add brake fluid to the reservoir of the master brake cylinder to the mark «MAX».

Attention! Add brake fluid only of the same brand as the one filled into the system.

2. Place the vehicle on an inspection ditch or lift.

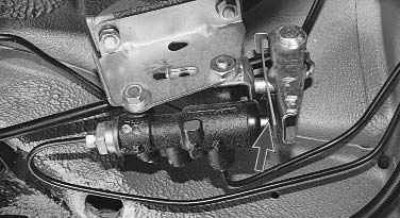

3. If the rear wheels are suspended, first unlock the rear brake pressure regulator by inserting a screwdriver between the plate and the piston. Don't forget to take it out when you're done.

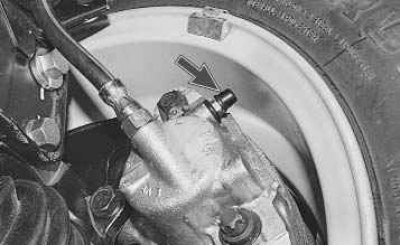

4. Clean the air release valve on the brake mechanism from which it is supposed to remove air from dirt and dust.

5. Remove the protective cap from the air release valve.

6. Place the rubber hose over the valve head and immerse the end in a clean, transparent container partially filled with brake fluid (the end of the hose must be immersed in the liquid).

7. The assistant should sharply press the brake pedal 4-5 times (with an interval between pressing 1–2 s). After the last stroke, keep the pedal depressed.

8. Loosen the air release valve 1/2 to 3/4 turn. Air bubbles will be visible in the liquid flowing from the hose. When fluid stops flowing from the hose, fully close the air release valve, after which the assistant should release the brake pedal.

9. Repeat steps 7 and 8 until there are no air bubbles in the escaping fluid. At the same time, control the level of brake fluid in the reservoir and, if necessary, add fluid, preventing the level from dropping below the mark «MIN».

10. Remove the hose, wipe dry the air outlet valve fitting and put on the protective cap. Bleed the brakes on the remaining wheels, if necessary.

Note. Do not reuse brake fluid drained during bleeding.

Note. If the bleeding of the hydraulic drive of the brake system is not done carefully enough, then when you press the pedal at the end of its stroke, an increased «softness» pedals.

Note. There are two ways to bleed the hydraulic brake system without an assistant. The first is the most reliable: order an aluminum or bronze cover for the main brake cylinder to the turner, screw the valve from the chamber into it and connect it with an additional hose to the spare wheel; air pressure should not exceed 0.05–0.07 MPa (0.5–0.7 kgf/cm2). The second one is not very reliable, but acceptable: connect the rubber bulb to the fitting of the wheel cylinder - the connection must be very tight. Squeeze the pear, unscrew the fitting; when the pear is half full, tighten the fitting. Repeat the procedure three or four times. During test braking, check the operation of the brakes.