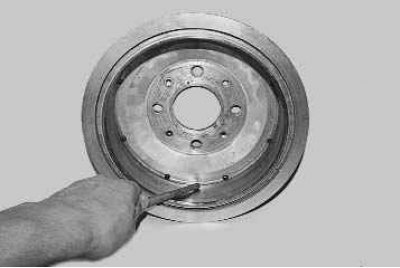

On the working surface of the drum there should be no burrs or deep scratches. Otherwise, replace the drum or grind its working surface on the machine.

After turning, grind the surface with fine-grained abrasive stones; after processing, the diameter of the drum should not exceed 201 mm.

Replace the drum if cracks are found in it.

You will need: key «on 7», two mounting blades, hammer, wooden spacer.

1. Engage 1st gear and place chocks under the front wheels.

2. Make sure the parking brake lever is pushed all the way down (the car is disinhibited).

3. Remove the rear wheel and clean the brake drum from dirt.

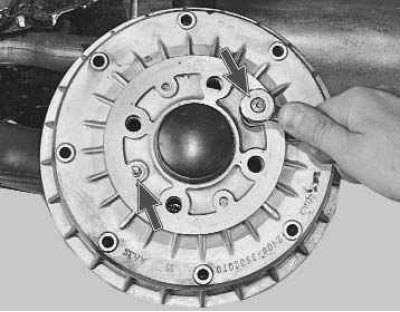

4. Key «on 7» unscrew the two dowel pins.

5. Apply WD-40 to the hub and wait a few minutes to clean off dirt and rust.

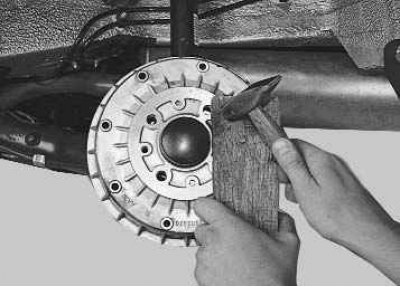

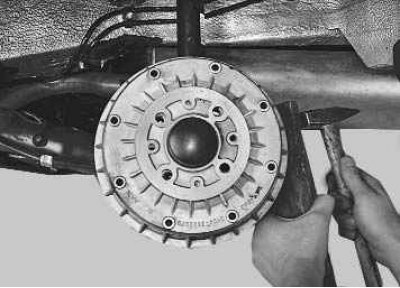

6. Hammer blows through the wooden spacer to remove the drum from the hub.

7. Remove the drum from the hub. If this fails, knock it down with a hammer, striking through a wooden spacer on the shoulder on the back of the drum...

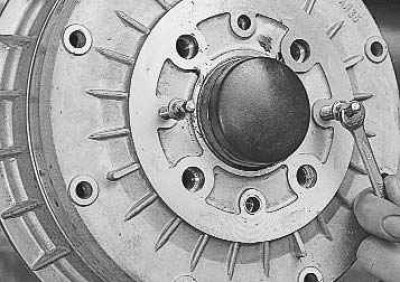

8....or compress by driving pins or suitable bolts evenly into the two threaded holes in the drum.

9. When installing the old drum, use a file to remove the shoulder on its working surface, formed as a result of wear.

10. Install the drum in the reverse order of removal. Pre-lubricate the seating belt of the hub with graphite grease or LSC-15 grease and bring the pads together using two mounting spatulas.

11. Check the ease of rotation of the wheel. Easy touching of the drum on the pads is allowed. With the vehicle on the ground, depress the brake pedal two or three times to bring the shoes to the drum.