If there are scuffs, deep scratches and other defects on the working surface of the disc that increase pad wear and reduce braking efficiency, replace the disc. In specialized workshops, such a disc can be machined and polished. But at the same time, the thickness of the disk must not be less than the minimum allowable value. The disk is machined on both sides to the same depth.

You will need: key «on 7», socket wrench (head) «at 17».

1. Remove the relevant wheel and brake pads.

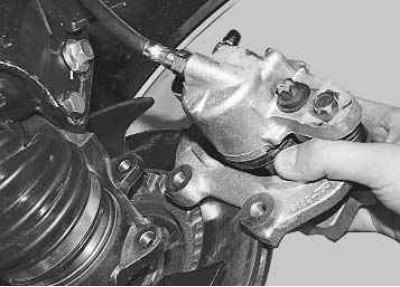

2. Key «at 17» unscrew the two bolts securing the guide pads to the steering knuckle..

3.... and remove the brake assembly without disconnecting the brake hose from the wheel cylinder.

4. Hang the brake mechanism on a rope or wire from the front suspension strut. At the same time, make sure that the brake hose is not twisted and is not too tight.

5. Clean the brake disc from dirt. Apply WD-40 to the disc/hub connections and drive pins. Wait a bit to allow the rust to dissolve.

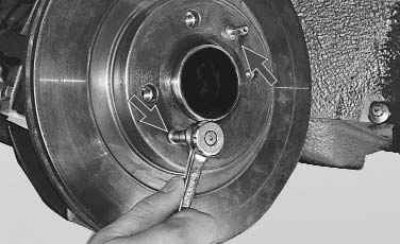

6. Key «on 7» unscrew the two guide pins..

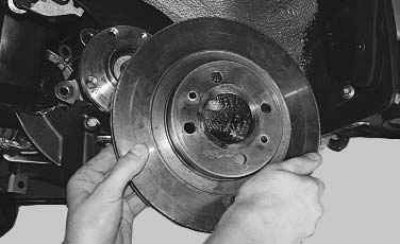

7.... and remove the brake disc.

8. Install the brake disc in reverse order. If you are installing an old disk, then remove the shoulders on both sides of it with a file, resulting from the wear of the disk.