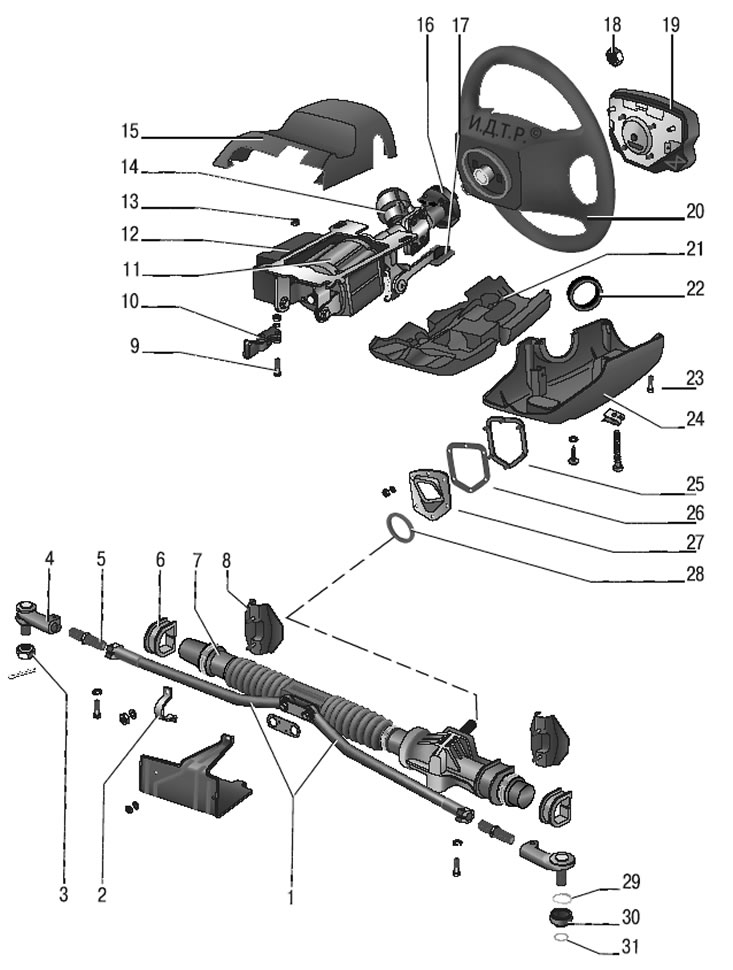

Pic. 8.1. Steering: 1 – internal tips of steering rods; 2 – a bracket of fastening of the steering mechanism; 3 – a nut of the hinge of steering draft; 4 – an external tip of steering draft; 5 - adjusting rod; 6 – a support of the steering mechanism; 7 – steering gear; 8 – an arm of fastening of the steering mechanism; 9 - coupling bolt; 10 - cardan shaft with a hinge; 11 - electromechanical power steering; 12 - electronic control unit of the electromechanical amplifier; 13 – a nut of fastening of a steering column; 14 - ignition switch; 15 - upper facing casing of the steering shaft; 16 - connector; 17 – steering column adjustment lever; 18 – a nut of fastening of a steering wheel; 19 - airbag; 20 - steering wheel; 21 - insert of the lower casing; 22 - sealing ring; 23 - fastening screw; 24 - the lower casing of the steering shaft; 25 - fastening element of the motor shield; 26 - gasket; 27 - thrust plate; 28 - sealant; 29 - spring ring; 30 - protective cover; 31 - sealing ring

The steering gear assembly with steering rods is attached in the engine compartment to the bulkhead shield of the body on two brackets using brackets 2 (pic. 8.1). The mechanism is fixed with nuts on welded bolts through rubber supports 6.

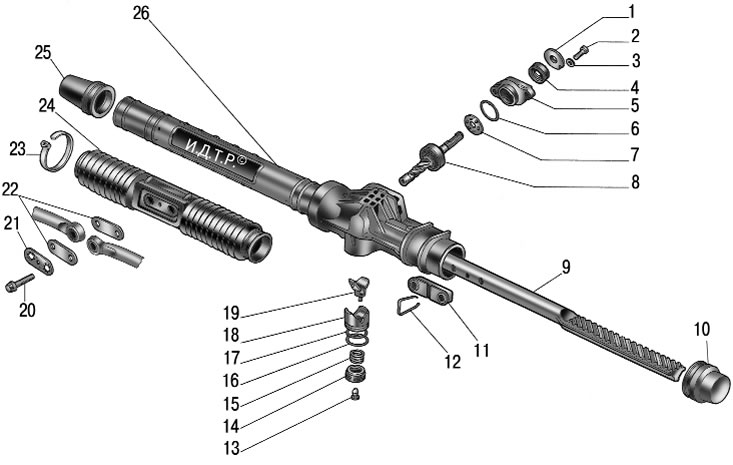

Pic. 8.2. Steering gear: 1 - anther; 2, 20 - bolts; 3 - washer; 4 - stuffing box; 5 - crankcase cover; 6, 17 - sealing rings; 7 - separator assembly; 8 - drive gear with bearing assembly; 9 – steering rack; 10 – left protective cap; 11 - support rods; 12 - bracket; 13 - plug; 14 - stop nut; 15 - stop spring; 16 - retaining ring; 18 - rail stop; 19 - stop insert; 21 - locking plate; 22 - cover plate; 23 - collar; 24 - protective cover; 25 - right protective cap; 26 - steering gear housing

In crankcase 26 (pic. 8.2) of the steering mechanism, a drive gear 8 is installed on ball and roller bearings, which is engaged with the rack 9. The ball bearing of the gear and the cage 7 are pressed by the cover 5 assembled with the stuffing box 4 and covered with anther 1.

On the crankcase of the steering mechanism and on the boot there are marks for the correct assembly of the steering mechanism.

The rack 9 is pressed against the teeth of the drive gear by a spring 15 through a ceramic-metal stop 18, sealed in the crankcase with a rubber ring 17. The spring is pressed by a nut 14 with a retaining ring 16, which creates resistance to loosening the nut.

A protective cap is put on the steering gear housing on the left side, and a pipe with a longitudinal groove is pressed on the right side, a protective cap is also put on the pipe on the right side. Spacer bushings of rubber-metal hinges of inner tips of steering rods pass through the groove of the pipe and holes in the protective cover 1 (see fig. 8.1). Steering rods are attached to the rack with bolts 20 (see fig. 8.2), which pass through the connecting plates 22 and the spacer bushings of the rubber-metal hinges. The bolts are fixed with a locking plate 21.

The steering drive consists of two composite steering rods and swing arms of the telescopic struts of the front suspension. The length of each steering rod is regulated by the rod 5 (see fig. 8.1), which is screwed into the inner 1 and outer 4 tips.

Information about malfunctions in the operation of the electric power steering is provided by its electronic control unit when the ignition is turned on by flashing a signal lamp in the instrument cluster (fault code light) (see «Electromechanical power steering control unit»).