1. Position the vehicle on an inspection ditch or raise and support the front of the vehicle. Remove the wheel.

Attention! Brake the vehicle with the parking brake and place wheel chocks under the rear wheels («shoes»).

Attention! Loosen and tighten the wheel bolts only with the vehicle on the ground. Bolt tightening torque 65–95 Nm (6.5–9.5 kgf·m).

2. Apply WD-40 to the lever threads.

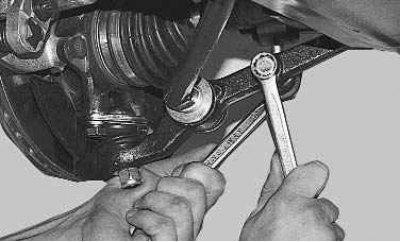

3. Turn away a nut of fastening of a rack of the stabilizer to the lever, keeping a bolt from turning, and take out a bolt.

4. Turn away a nut of fastening of an extension to the lever, holding an extension with a key that it did not turn in rubber-metal hinges.

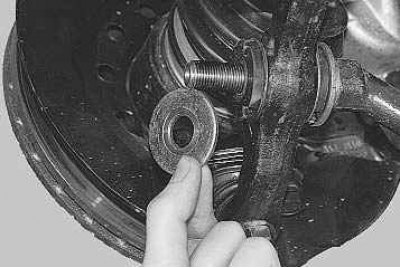

5. Remove the special washer.

6. Press the ball joint pin out of the lever (see «Ball joint replacement»).

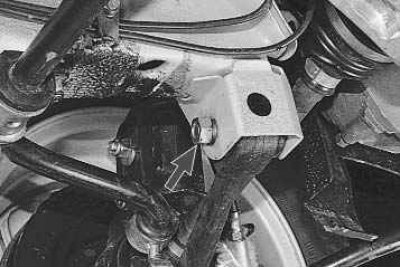

7. Turn away a nut of fastening of the lever, holding a bolt from turning, remove a spring washer and take out a bolt.

8. Take out the end of the lever from an arm on a body and remove the lever from an extension.

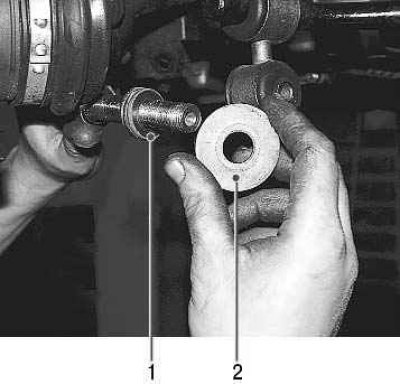

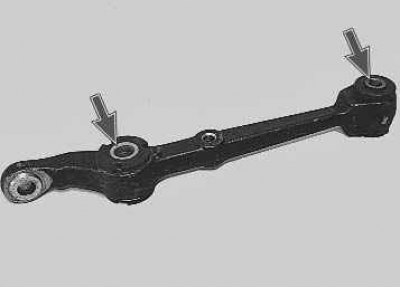

9. Remove the special washer 2 and the package of shims 1 from the brace, counting their number (if they are installed). Mark the washers to later install them on the same side of the lever.

10. Signs of wear of the rubber-metal hinges of the lever are breaks and one-sided bulging of the rubber, delamination of the rubber from the metal bushing.

Replacing rubber-to-metal linkage joints requires special tools and skill.

11. Install the new lever in the reverse order of removal. Set the adjusting washers in the same quantity, and the chamfers on their inner diameters should be directed towards the stop collar of the brace. Finally tighten the suspension bolts with the vehicle on the ground. After lowering the car to the ground, rock it hard several times. Tighten the nuts securing the ball joint to the lever and securing the lever to the body bracket to a torque of 80–96 Nm (8.0–9.6 kgf·m), a nut for fastening the extension to the lever with a torque of 160–180 N·m (16.0–18.0 kgf·m), a nut of fastening of a rack of the stabilizer of cross stability to the lever the moment of 42–52 Nm (4.2–5.2 kgf·m). After a run of 100 km, re-tighten these threaded connections to the specified torques.