Mod generator. 5102.3771 has a number of advantages over early analogues of domestic production. The most significant difference is the increased current output of the generator at low engine speeds (the increase is 4–6 A with a decrease in the generator rotor speed by 300 min-1), which is especially necessary when operating a car in winter, and will also allow using an automatic transmission in the car design in the future.

Technical characteristics of the generator 5102.3771

- Maximum recoil current at 14 V, A - 80

- Regulated voltage, V — 13.8–14.4

- Gear ratio engine - generator - 1: 2.4

- Specific power, W/kg — 205

- Weight, kg - 5.4

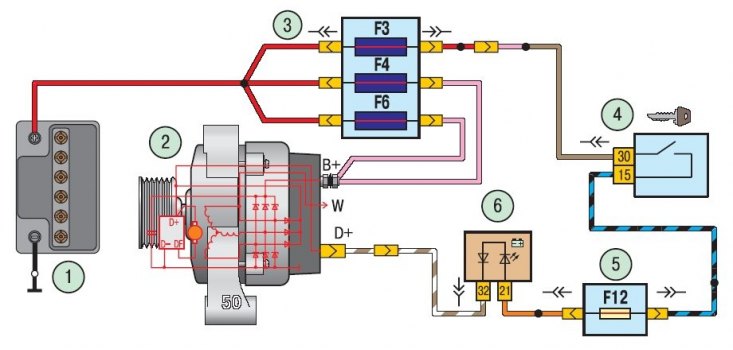

Pic. 10.1. Generator connection diagram: 1 - rechargeable battery; 2 - generator; 3 - main fuse block; 4 - switch (lock) ignition; 5 - mounting block; 6 - battery discharge warning light

The generator connection diagram is shown in fig. 10.1. The voltage to excite the generator when the ignition is turned on is supplied to the output «D+» regulator through the signal lamp of the 6th discharge of the battery, located in the instrument cluster.

After starting the engine, the excitation winding is powered by three additional diodes installed on the rectifier unit of the generator.

Conclusion «W» generator on Lada Priora cars is not used.

The operation of the generator is monitored using a low battery warning light located in the instrument cluster. When the ignition is turned on, the lamp should be on, after starting the engine it should go out if the generator is working. The bright burning of the lamp or its burning half-heartedly indicates malfunctions.

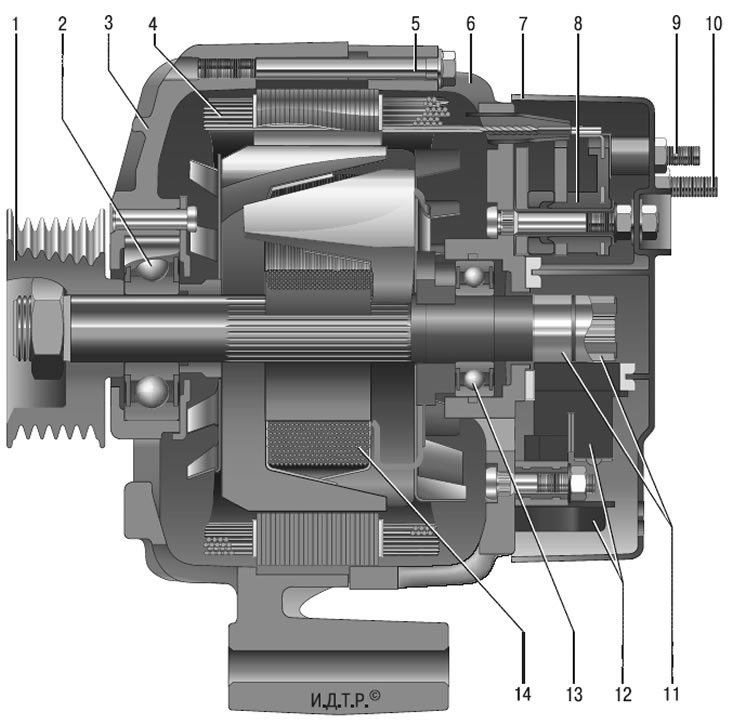

Pic. 10.2. Generator 5102.3771: 1 - pulley; 2 - front bearing; 3 - front cover; 4 - stator; 5 - coupling bolt; 6 - back cover; 7 - casing; 8 - rectifier block; 9 - output «D+» generator; 10 - output «B+» generator; 11 - contact rings of the rotor; 12 - voltage regulator with brush holder; 13 - rear bearing of the rotor shaft; 14 - rotor

Stator 4 (pic. 10.2) and covers 3 and 6 are tightened with four screws. The rotor shaft 14 rotates in bearings 2 and 13, which are installed in the covers. Power to the rotor winding (excitation winding) is supplied through brushes and slip rings 11.

The three-phase alternating current induced in the stator winding is converted into a direct current by a rectifier unit 8 attached to the cover 6. The electronic voltage regulator 12 is combined into one unit with a brush holder and is also attached to the cover 6.