Recommendations. Check tire pressure periodically. High or low pressure leads to premature tire wear, poor handling and vehicle stability.

We recommend using a foot pump with a built-in pressure gauge.

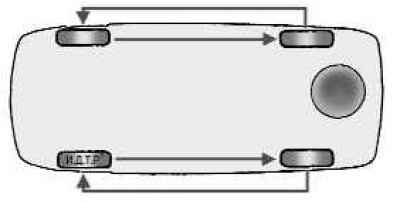

Pic. 4.1. Wheel swap diagram

In order for the tires to wear evenly, every 15,000 km of run (at the next maintenance) rearrange the wheels in accordance with the diagram in fig. 4.1. After the first 15,000 km and then every 30,000 km, balance the wheels and check the wheel alignment. To do this, contact a specialized workshop.

Attention! Carry out all wheel repair work in specialized workshops. Check that all wheels are balanced after repair.

Warning! Using tires with worn tread can lead to an accident.

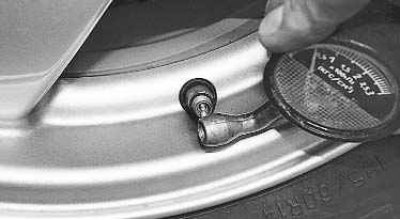

1. Unscrew the cap from the valve.

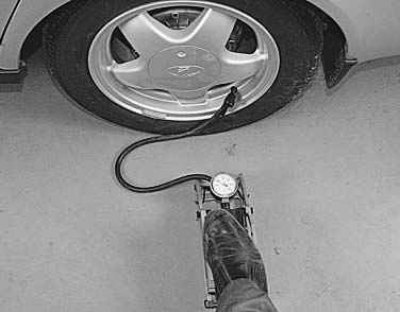

2. Check tire pressure. To do this, reset the pressure gauge to zero by pressing a special button on the pressure gauge housing..

3.... connect a pressure gauge to the valve and press it with the tip of the pressure gauge.

4. If the pressure is less than required, connect the hose tip to the valve and pump air, controlling the pressure on the manometer.

5. If the pressure is more than required, press the special protrusion of the pressure gauge on the tip of the spool and release the air from the tire. Measure the pressure with a manometer. By repeating these operations, bring the pressure to normal.

Note. It looks like a special protrusion of the pressure gauge for bleeding air from the tire.

6. If you notice that the air pressure in the tires is constantly dropping, try tightening the spool with a cap with a key.

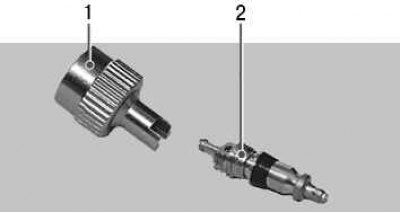

Note. This is what the protective cap 1 looks like with the key for tightening the spool 2.

Attention! In order to avoid contamination of the spools, do not operate the vehicle without protective caps. If the caps have been lost, be sure to install new ones.

7. In order to check the tightness of the spool, wet the valve hole. If air bubbles appear, replace the spool.

8. Measure the residual tread depth with a caliper. If the tread depth is 1.6 mm or less, replace the tire.

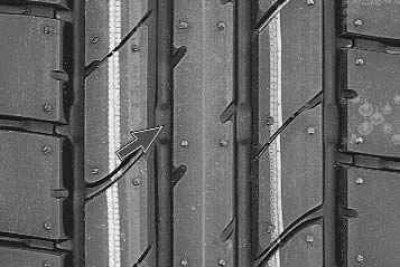

9. If there is no caliper at hand, the tread depth can be checked visually by the tire wear indicators in the form of continuous transverse stripes that appear on the tread at its maximum wear.

Note. Indicator locations are marked on the sidewall of the tire with triangles or an abbreviation «TWI» (depending on which notation the tire manufacturer uses).

10. To check the tightness of the wheel, unscrew the screw securing the decorative cap to the rim..

11.... and remove the cap.

12. Check up an inhaling of nuts of fastening of wheels and if necessary tighten them the moment of 88–108 Нм.