You will need: a portable lamp, a set of flat probes, a ruler, a caliper, a caliper, a micrometer, a scraper.

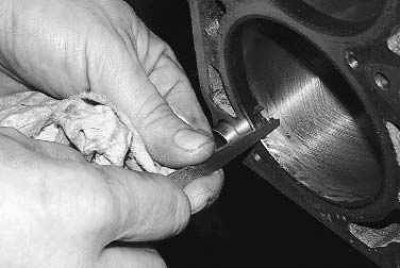

1. Clean the piston head from carbon deposits. If the piston has scuff marks, traces of burnout, deep scratches, cracks, replace the piston. Clean the grooves for the piston rings. It is convenient to do this with a piece of the old ring.

2. Clean the oil drain holes with a suitable piece of wire.

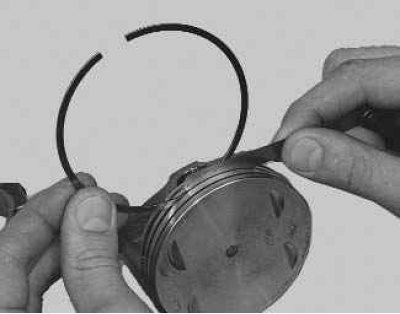

3. Check up backlashes between rings and flutes on the piston, preliminary having cleared rings of a deposit.

Nominal clearance, mm:

- 0.04–0.075 - upper compression ring 1;

- 0.03–0.065 - lower compression ring 2;

- 0.02–0.055 - oil scraper ring 3.

The maximum allowable clearance for all rings is 0.15 mm.

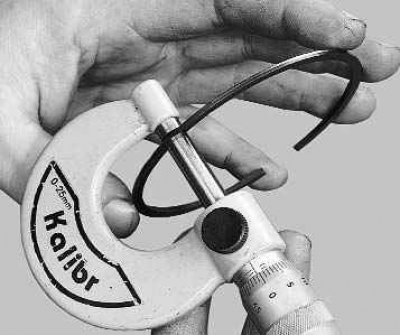

4. The most accurate gaps can be determined by measuring the rings and grooves on the piston. To do this, measure the thickness of the rings with a micrometer in several places around the circumference, then use a set of feeler gauges to measure the width of the grooves also in several places around the circumference. Calculate Average Clearances (difference between ring thickness and groove width). If at least one of the gaps exceeds the maximum allowable, replace the piston with rings.

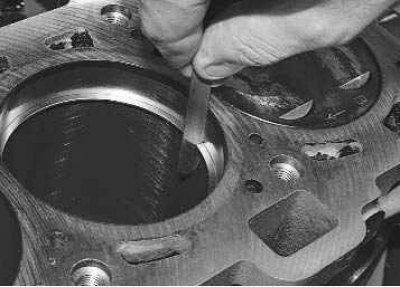

5. Measure the gaps in the locks of the rings by inserting the ring into a special mandrel. If there is no mandrel, insert the ring into the cylinder in which it worked (or will it work if the ring is new), move the piston like a mandrel into the cylinder so that it is installed in the cylinder evenly, without distortions and measure the gap in the ring lock with a feeler gauge. The nominal gap must be 0.25–0.45 mm, the maximum allowable (as a result of wear) - 1.0 mm. If the gap exceeds the limit, replace the ring.

6. If the gap is less than 0.25 mm, carefully grind off the ends of the ring with a needle file.

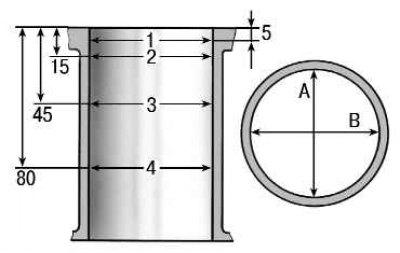

Pic. 5.14. Cylinder Measurement Diagram

7. Measure the cylinder diameters in two perpendicular planes (pic. 5.14) (B - along, A - across the cylinder block) and four belts (1, 2, 3 and 4). To do this, you need a special device - a caliper. Nominal cylinder size (see table. 5.1), ovality and taper should not exceed 0.05 mm. If the maximum wear value is greater than 0.15 mm or the out-of-roundness exceeds the specified value, bore the cylinders to the nearest oversize of the pistons, leaving an allowance of 0.03 mm for the honing diameter. Then honing the cylinders, maintaining such a diameter that when installing the piston, the calculated clearance between it and the cylinder was 0.025–0.045 mm. Troubleshooting, boring and honing of the block should be carried out in workshops with special equipment.

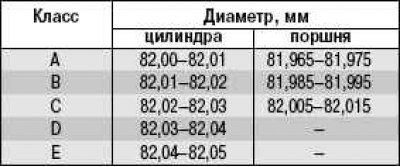

Table 5.1. Nominal sizes of cylinders and pistons

8. Check up a deviation from flatness of a surface of a socket of the block with a head of cylinders. Attach a caliper (or ruler) to plane:

- in the middle of the block;

- in longitudinal and transverse directions;

- along the diagonals of the plane.

At each position, use a feeler gauge to determine the gap between the ruler and the plane. This is the deviation from flatness. If the deviation exceeds 0.1 mm, replace the block.

9. Check up backlashes between pistons and cylinders. The clearance is defined as the difference between the measured piston and cylinder diameters. The nominal gap is 0.025–0.045 mm, the maximum allowable gap is 0.15 mm. If the gap does not exceed 0.15 mm, pistons from subsequent classes can be selected so that the gap is as close to the nominal as possible. If the gap exceeds 0.15 mm, bore the cylinders and install pistons of the appropriate oversize. Measure the piston diameter at a distance of 10 mm from the lower edge of the skirt in a plane perpendicular to the piston pin.

10. When replacing parts of the connecting rod and piston group, it is necessary to select pistons for cylinders by class and one group by weight, as well as piston pins for pistons by class and connecting rods by weight. To match pistons to cylinders, calculate the gap between them. For the convenience of selecting pistons for cylinders, they are divided depending on the diameters into five classes through 0.01 mm: A, B, C, D, E (tab. 5.1).

Spare parts are supplied with pistons of nominal size of three classes: A, C, E and two repair sizes (1st repair size - increased by 0.4 mm, 2nd - by 0.8 mm).

By weight, the pistons are divided into three groups: normal, increased by 5 g and reduced by 5 g. Pistons of the same group must be installed on the engine.

For oversized pistons, spare parts are supplied with oversized rings increased by 0.4 and 0.8 mm. On the rings of the 1st repair size, a number is stamped «40», 2nd - «80».

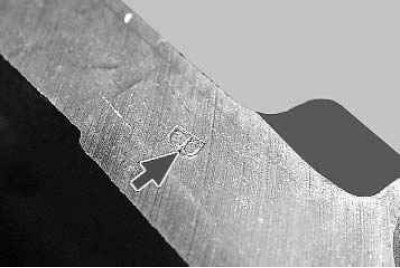

11. Designations of the class of cylinders are embossed on the bottom plane of the block (mating surface for oil sump) opposite each cylinder.

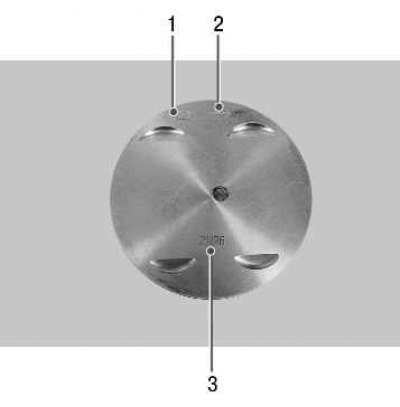

12. The following data is stamped on the bottom of the piston: 1 - piston class by diameter; 2 - an arrow showing the direction of installation of the piston; 3 - engine model.

13. Replace cracked fingers. The finger should easily enter the piston with the force of the thumb. Insert your finger into the piston. If play is felt when shaking the finger, replace the piston. When replacing a piston, select a finger according to the class.

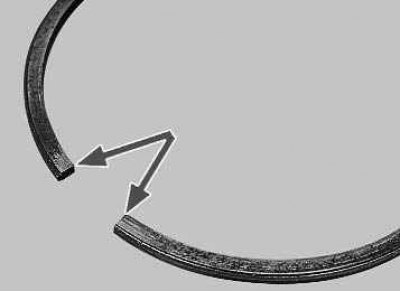

14. Replace broken rings and oil ring expander.

15. Replace broken or cracked circlips holding the piston pin. The ends of the retaining rings must be in the same plane. Replace bent rings.

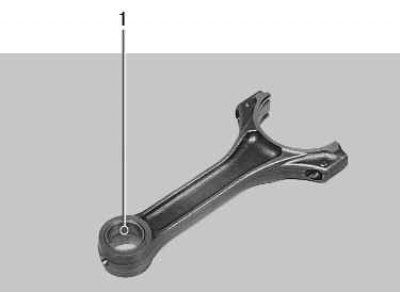

16. Replace bent connecting rods. Replace the connecting rod if there are scores and deep scratches in the sleeve 1 of the upper head. Replace the connecting rod if, during disassembly of the engine, it is found that the connecting rod bearings have turned in the connecting rod.

Attention! The connecting rods are processed together with the covers, so they cannot be dismantled.

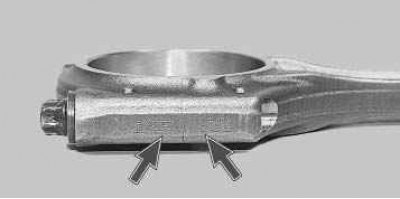

17. Insert a finger into the top head of a rod. If play is felt when the finger is wiggled, replace the connecting rod. Connecting rods complete with caps are divided into classes according to the mass of the upper and lower heads.

18. Connecting rods of the same class must be installed in the engine. The connecting rod marking is on the bottom head and connecting rod cap.

19. If there are deep risks, scratches, nicks on the surfaces on which the seals work, the crankshaft must be replaced.

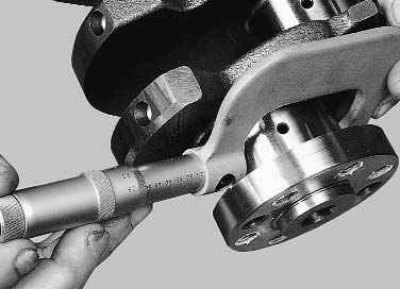

20. Measure the main and connecting rod journals of the crankshaft. Nominal diameters of crankshaft journals, mm:

- indigenous - 50.799–50.819;

- connecting rod - 47.830–47.850.

If the wear or ovality of the necks exceeds 0.03 mm, they must be ground to the nearest repair size.

There are four repair sizes with a decrease in the diameter of the necks, mm:

- the first - 0.25;

- the second - 0.5;

- third - 0.75;

- fourth - 1.00.

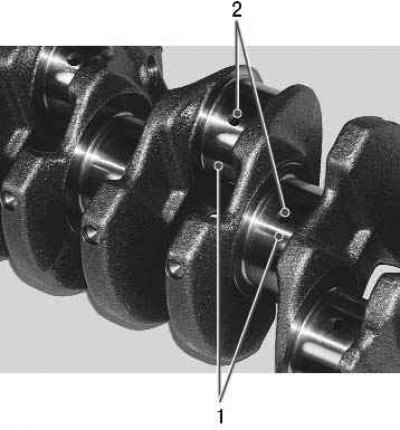

21. If there are minor scuffs, risks, scratches on the main and connecting rod journals 1, you need to grind them to the nearest repair size. This work is recommended to be carried out in a specialized workshop. After grinding, polish the necks and dull the sharp edges of the chamfers of the oil channels 2 with an abrasive cone. Wash the crankshaft and blow out the oil passages with compressed air. The ovality and taper of all necks after grinding should not exceed 0.005 mm. After grinding the necks, install the bushings of repair sizes.

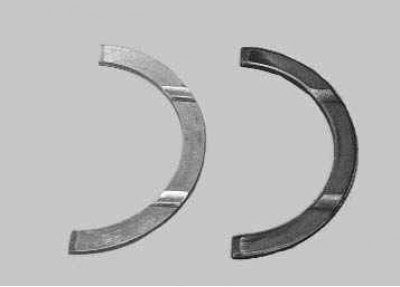

22. If there are scores, risks and delaminations on the working surfaces of the thrust half rings, replace the half rings. It is forbidden to carry out any fitting work on the half rings.

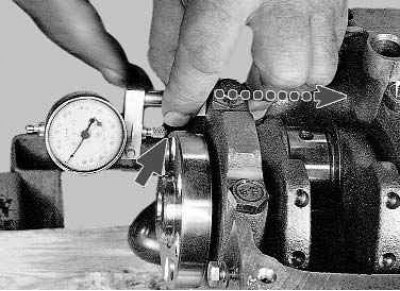

23. Measure the axial clearance of the crankshaft. To do this, install the crankshaft and thrust half rings in the cylinder block and tighten the bolts securing the main bearing caps (see «Engine Assembly»).

24. Install the indicator so that its leg rests against the shaft flange. Slide the crankshaft away from the indicator until it stops and set the indicator needle to zero. Slide the shaft back. The indicator will show the gap. The nominal axial clearance of the crankshaft is 0.06–0.26 mm, the maximum allowable is 0.35 mm. If the gap exceeds the maximum allowable, replace the thrust half rings.

Spare parts are supplied with thrust half rings of two sizes: nominal - 2.31–2.36 mm and repair (increased by 0.127 mm) - 2.437–2.487 mm.

25. Inspect the connecting rod and main bearings. Replace liners with cracks, scoring, chipping. It is forbidden to carry out any adjustment work on the liners.

Nominal thickness of liners, mm:

- indigenous - 1.824–1.831;

- connecting rod - 1.723–1.730.

Inserts are supplied in spare parts of four repair sizes, increased thickness, mm:

- the first - by 0.25;

- the second - by 0.50;

- the third - by 0.75;

- the fourth - by 1.00.

26. Check up backlashes between loose leaves of radical bearings and necks of a cranked shaft. This work is recommended to be carried out in a specialized workshop. Measure the diameters of the journals and main bearings by installing the bearing caps on the block and tightening them to the correct torque. Calculate clearance. Clearances between bearings and crankshaft journals:

- main bearings (nominal 0.026–0.073 mm, maximum allowable 0.15 mm);

- connecting rod bearings (nominal 0.02–0.07 mm, maximum allowable 0.1 mm).

If the gap exceeds the maximum allowable, the crankshaft must be ground to the next repair size.

Attention! When regrinding the connecting rod and main journals of the crankshaft to the repair size on the first cheek of the crankshaft, it is necessary to put the appropriate stamp, for example, W 0.25 and K 0.25, respectively.

27. In a specialized workshop, you can measure the runout of the crankshaft journals.

The beat should be:

- main journals and seating surface for the oil pump drive gear no more than 0.03 mm;

- landing surface for the flywheel is not more than 0.04 mm;

- landing surface for pulleys and seals is not more than 0.05 mm.

28. Thoroughly clean and flush the crankshaft oil passages.

29. It is not recommended to press out the plugs yourself; for this, contact a specialized workshop.

30. Thoroughly clean the surfaces of the cylinder block from the remnants of old sealing gaskets. Check the block carefully. If cracks are found, the block must be replaced complete with main bearing caps.

31. Check up tightness of a jacket of cooling of the block of cylinders. To do this, plug the hole for the water pump (installing a pump with a gasket) and pour antifreeze into the cooling jacket. If a leak is noticeable in any place, then the block is leaky and must be replaced.

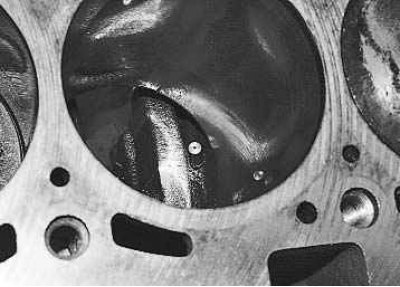

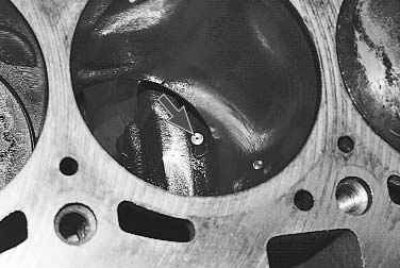

32. Inspect the cylinders. If there are scratches, scuffs, shells and other defects on the cylinder mirror, bore the cylinders to the repair size (this work is recommended to be carried out in a specialized workshop) or replace the cylinder block. With various defects deeper than 0.8 mm, the unit cannot be repaired and must be replaced.

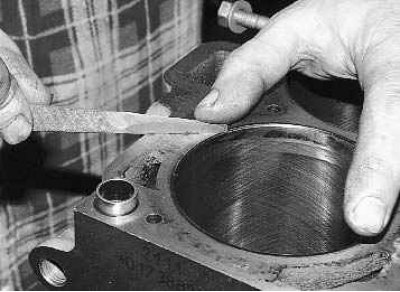

33. Clear a deposit in the top part of cylinders. If a belt has formed there due to cylinder wear, remove it with a scraper.

34. Check up presence of nozzles for cooling of the bottom of the piston and firmness of their landing in openings of beds of the block of cylinders.