You will need: all the tools needed to remove the cylinder head cover (see «Replacing the cylinder head cover gasket»), timing gear drive (see «Replacing the timing belt and tensioner pulley»), rear timing belt cover (see «Replacing the cylinder head gasket»), cylinder head removal (see «Replacing the cylinder head gasket»), and also tweezers (or magnetized screwdriver) for extracting crackers from the plates of valve springs..

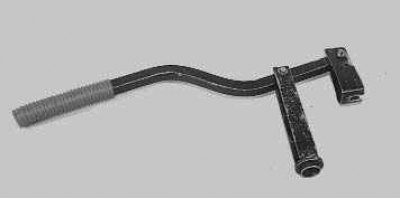

... a valve spring compressor..

... a tool for removing and mandrel for installing valve stem seals.

1. Disconnect the terminal wire «minus» battery.

2. Remove the spark plugs (see «Replacement and maintenance of spark plugs»).

3. Set the piston of the 1st cylinder to the TDC position of the compression stroke (see «Setting the piston of the first cylinder to the TDC position of the compression stroke»).

4. Remove the timing belt (see «Replacing the timing belt and tensioner pulley»).

5. Remove the camshaft pulleys (see «Replacing the cylinder head gasket»).

6. Remove the rear timing belt guard (see «Replacing the cylinder head gasket»).

7. Remove the cylinder head cover (see «Replacing the cylinder head cover gasket»).

8. Remove the block head (see «Replacing the cylinder head gasket»).

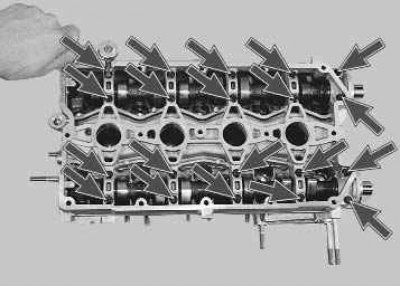

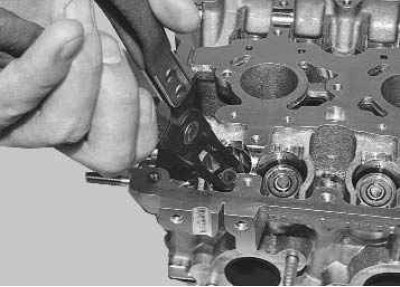

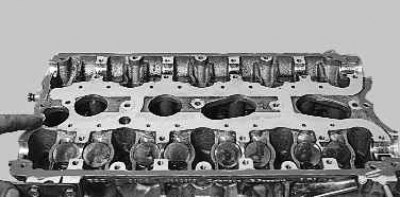

9. Turn out the socket «for 8» twenty bolts securing the camshaft bearing housing...

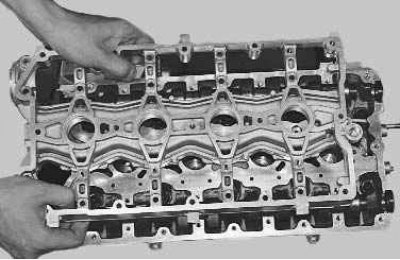

10.... and remove the case.

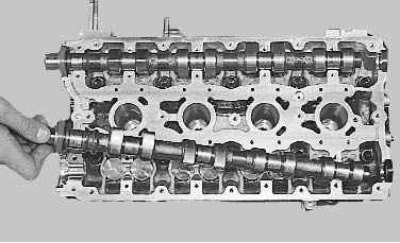

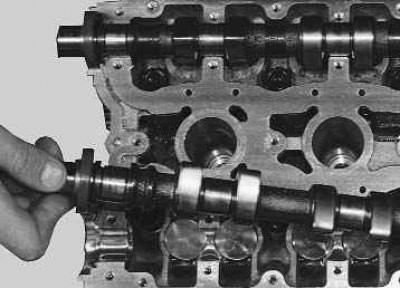

11. Take out camshafts from support of a head of the block of cylinders.

12. Remove the valve lifters from the holes in the cylinder head.

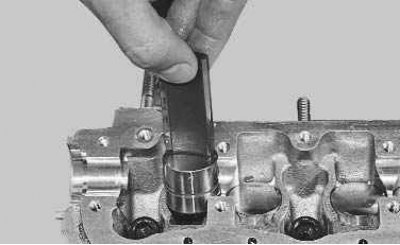

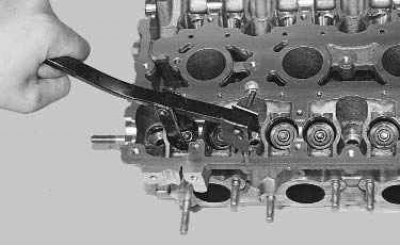

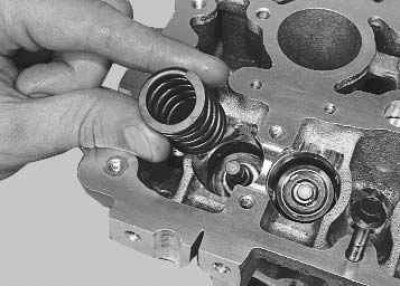

13. Install the valve spring compressor by screwing the camshaft bearing cap bolt into one of the holes in the head of the block and hooking the tool onto this bolt. Compress the valve spring with the tool.

14. Remove two crackers from the upper spring plate using tweezers or a magnetized screwdriver. Then remove the fixture.

Note. If the force of moving the lever of the device increases significantly, and the crackers do not come out of the valve groove, apply a light blow with a hammer on the spring plate so that the crackers are released.

15. Remove the spring plate.

16. Remove the spring.

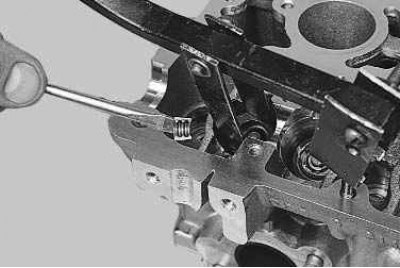

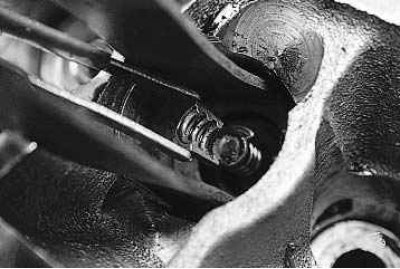

17. Press the valve stem seal off the valve guide.

Attention! If there is no tool for removing caps, carefully remove them with pliers. The force must be applied strictly upwards and do not turn the caps so as not to damage the valve guides. The use of two screwdrivers for this purpose is prohibited!

Note. If the set of new caps includes a mounting sleeve, put it on the valve stem to protect the working edge of the cap from damage by the sharp edges of the cracker grooves on the valve stem.

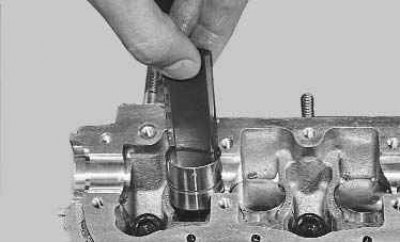

18. Dip the valve stem seal in engine oil and insert it into the mandrel.

19. Carefully press the cap in until it stops.

Note. If a guide sleeve was installed on the valve stem, remove it.

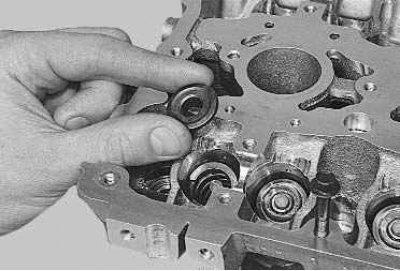

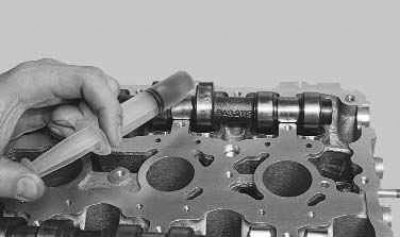

20. Establish springs and plates of springs.

21. Compressing the spring with a tool, install the crackers so that they fit into the grooves of the valve stem.

Note. After installing the crackers and removing the valve spring compressor, apply a few light blows with a hammer on the end of the valve stem so that the crackers are guaranteed to be fixed in the groove of the stem. If the crackers installed with a warp remain unfixed, when starting the engine «cracked» the valve will fall into the cylinder, resulting in a serious engine failure.

22. Install the valve lifter.

23. Similarly, replace the valve stem seals of the remaining valves.

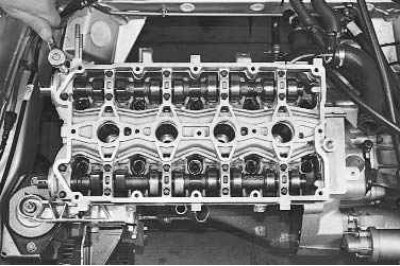

24. Install the block head on the engine (see «Replacing the cylinder head gasket»).

25. Lubricate the camshaft bearings in the block head and hydraulic pushers with engine oil.

26. Install the camshafts in the block head bearings so that the cams of the 1st cylinder are directed away from the valve lifters.

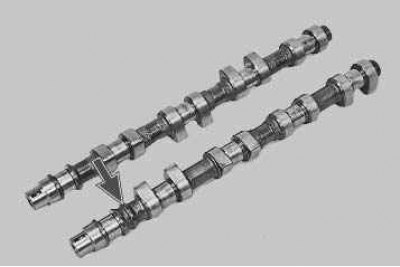

Note. The intake camshaft is equipped with a distinctive belt.

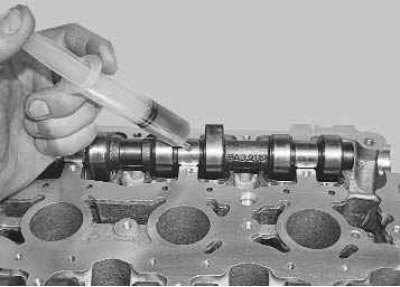

27. Lubricate the necks with engine oil..

28.... and camshaft cams.

29. On the surface of the cylinder head mating with the camshaft bearing housing, apply a type of sealant «Loctite-574» roller with a diameter of 2 mm.

Attention! It is allowed to start the engine no earlier than 1 hour after applying the sealant.

30. Install the bearing housing and tighten its fastening bolts evenly in a cross pattern, starting from the middle supports.

Note. The bearing housing is centered by bushings pressed into the cylinder head. Before installing the housing, check their presence and correct pressing.

31. Install the removed parts of the gas distribution mechanism (see «Replacing the cylinder head gasket») and adjust the timing belt tension (see «Replacing the timing belt and tensioner pulley»).

32. Install the removed parts of the generator drive and adjust the tension of the generator drive belt (see «Checking the alternator drive belt tension»).