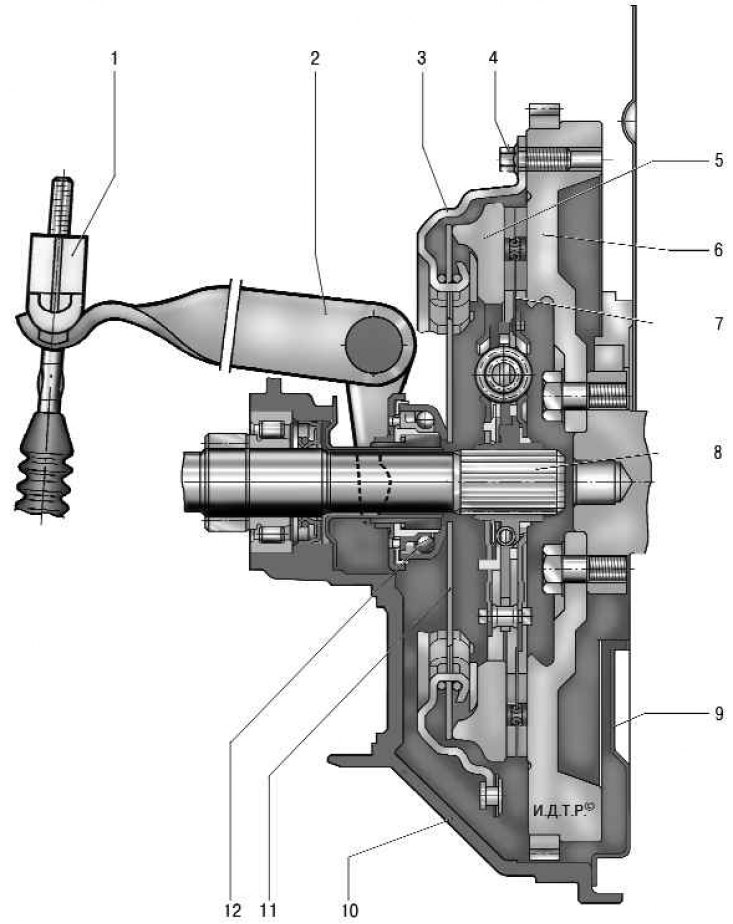

Pic. 6.1. Clutch: 1 - cable tip leash; 2 – the lever of a fork of deenergizing of coupling; 3 - clutch cover; 4 – a bolt of fastening of coupling to a flywheel; 5 - pressure plate; 6 - flywheel; 7 - driven disk; 8 – a primary shaft of a transmission; 9 - front cover of the clutch housing; 10 - clutch housing; 11 - pressure spring; 12 - clutch release bearing

Single disc clutch, dry, permanently closed, with central pressure spring 11 (pic. 6.1, 6.3) and a torsional vibration damper on the driven disk 7. The clutch cover 3 is attached to the flywheel 6 with six bolts 4, and is connected to the pressure disk 5 by three pairs of elastic plates.

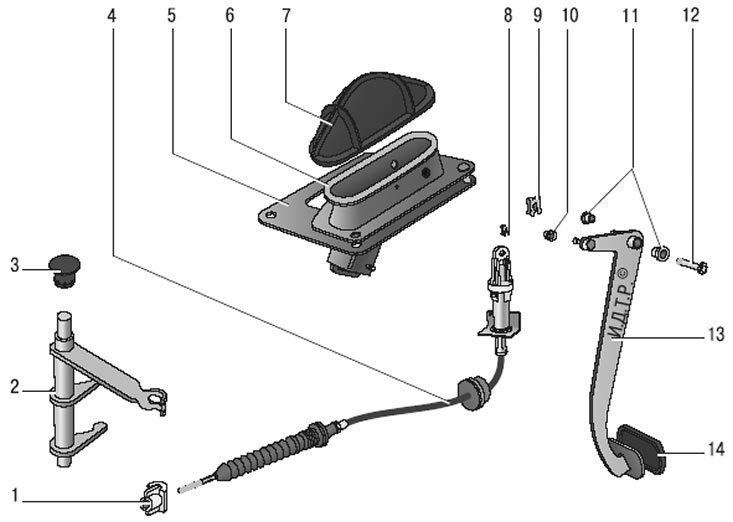

Pic. 6.2. Clutch Release Drive: 1 - cable leash; 2 - clutch release fork; 3 - bushing of the fork axle; 4 - cable; 5 - sealant; 6 - clutch pedal bracket; 7 - case; 8 - locking bracket; 9 - bracket; 10 - bushing; 11 - clutch pedal axle bushing; 12 – an axis of a pedal of coupling; 13 – clutch pedal; 14 - clutch pedal pad

Clutch release drive cable, backlash-free (there are no gaps in the drive). Rope 4 (pic. 6.2) the clutch release actuator is equipped with a ratchet-type mechanism designed to compensate for the length during operation when the lining of the driven disk is worn (drive adjustment in operation is not required).

The clutch pedal 13 is installed in the bracket 6, fixed on the front panel, on the axle through two plastic bushings. The upper part of the pedal is connected to the body of the mechanism for compensating for the wear of the clutch disc linings. The upper end of the cable sheath is fixed to the clutch pedal bracket with a plate stop, and the lower end of the cable is fixed to the bracket mounted on the gearbox housing.

Plastic leash 1 (see fig. 6.1) the lower tip of the cable is connected to lever 2 of the clutch fork. The clutch release bearing 12 is of a closed type and does not require lubrication during operation. The main parameter that determines the operation of the clutch release actuator is the travel of the clutch pedal until it stops against the floor mat of the body. The pedal stroke in operation is not adjustable, it is provided by a structurally sound mechanism for compensating for wear of the lining of the clutch disc and the correct initial installation of the drive cable (see «Replacing the clutch release cable»).

Note. In order for the clutch to serve for a long time and without fail, do not constantly keep your foot on the clutch pedal. This bad habit is often acquired while learning to drive in driving schools for fear of not having time to turn off the clutch while the car is stopped. In addition to the rapid fatigue of the foot, which is all the time above the pedal, the clutch is at least a little, but squeezed out, and the driven disk slips and wears out. In addition, although the release bearing is designed to operate in constant rotation mode, when the pedal is pressed even a little, it experiences an increased load and its life is also reduced.

Note. For the same reason, we do not recommend keeping the clutch in the off position for a long time (e.g. in traffic jams). If you do not have to move immediately, it is better to put the gearbox in neutral and release the pedal.

Note. Clutch slip is easy to determine with a tachometer. If, while driving, with a sharp press on the accelerator pedal, the speed rises sharply, and then falls slightly and the car starts to accelerate, the clutch needs to be repaired.