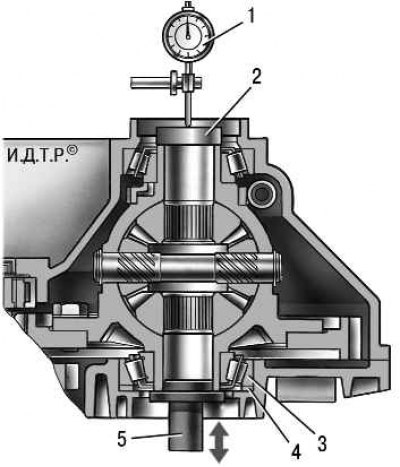

Pic. 6.10. Scheme for selecting the thickness of the differential bearing adjusting ring: 1 - indicator; 2 - base plate; 3 - differential bearing; 4 - adjusting ring; 5 - mandrel

The differential bearing preload should be 0.15–0.35 mm. Preload is ensured by selecting the thickness of the adjusting ring from those supplied as spare parts. The adjusting ring is installed in the socket of the gearbox housing under the outer ring of the differential bearing. The scheme for selecting the thickness of the differential bearing adjusting ring is shown in fig. 6.10.

1. Press the differential bearing outer race out of the gearbox housing if this has not already been done (see «Differential repair»).

2. Insert a 1.25 mm set ring into the differential bearing housing in the gearbox housing and press the differential bearing outer race into the transmission housing housing using a suitable drift. Press the bearing race into the clutch housing if it has been pressed out.

3. Install the differential in the gearbox housing.

4. Install the clutch housing on the gearbox housing and screw in the three crankcase mounting bolts equidistant from each other to the appropriate torque. Rotate the differential a few turns to self-align the bearings.

5. Install a base plate of the appropriate diameter on the end face of the differential flange on the side of the clutch housing.

6. Mount the indicator on the stand. Place the indicator leg on the base plate with a preload of 1 mm.

7. Using force from below, move the differential up until it stops. In this case, the differential cannot be rotated around the axis.

8. Measure the axial movement of the differential by reading the indicator. Calculate the required differential bearing shim thickness using the formula

T = S + C + Y, Where

T - the required thickness of the adjusting ring, mm;

S - measured axial displacement of the differential, mm;

C - differential bearing preload equal to 0.25 mm;

Y - the thickness of the adjusting ring, equal to 1.25 mm.

Select an adjusting ring of the calculated thickness from the supplied spare parts (T±0,1) mm.

Example of calculating the thickness of the adjusting ring

The axial clearance S when the indicator is displayed is 0.95 mm. We substitute this value into the formula, the value of the bearing preload (C=0.25mm) and the thickness of the adjusting ring (Y = 1.25 mm). We get T = 0,95 + 0,25 + 1,25 = 2,45 (mm).

The resulting thickness T of the adjusting ring must be (2,45±0,1) mm.

Install the selected adjusting ring into the housing of the gearbox housing and press in the outer race of the differential bearing.