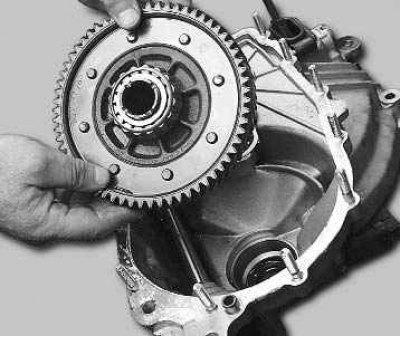

Attention! If during the repair of the gearbox, at least one of the following parts was replaced: clutch or gearbox housing, differential housing or differential bearings, then it is necessary to select the differential bearing adjusting ring.

You will need: socket wrench (head) «on 10», «at 13», «at 32», keys «on 10» And «at 17», large screwdriver, punch, hammer, circlip pliers, impact screwdriver.

1. Remove the gearbox from the car (see «Removal and installation of a transmission»). Clean it of dirt and wash the outside.

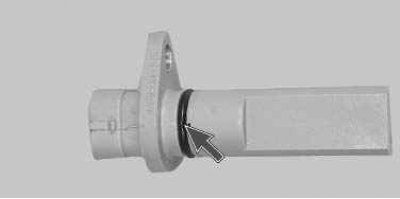

2. Take out the pointer (probe) oil level from the gearbox.

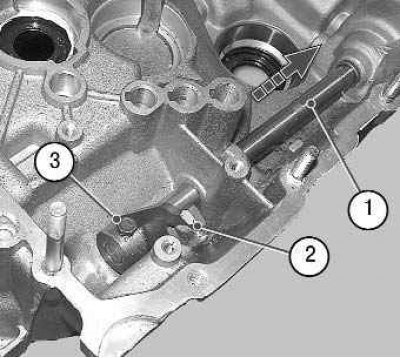

3. Install the gearbox on the clutch housing vertically, with a wrench «on 10» remove bolt 1 (a flat washer is installed under its head) and two nuts 3 (spring washers are installed under them) clutch cable bracket. Remove bracket 2 for clutch cable from gearbox.

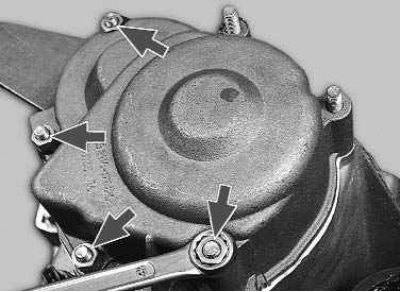

4. Key «on 10» unscrew the remaining four nuts securing the rear cover.

5. Using a screwdriver, pry off the tide on the cover, remove the back cover.

6. Key «on 10» unscrew the fastening bolt of the V gear fork (there is a spring washer under the head of the bolt).

7. Secure the gearbox shafts from turning. To do this, turn on the 5th gear by moving the synchronizer clutch down with the fork so that the clutch splines engage the gear, then turn on the 3rd or 4th gear by moving the gear selection rod.

8. Unlock and head «at 32» unscrew the nut securing the input shaft. To do this, you need to make a lot of effort, since the nut is tightened with a large moment.

9. Pre-unlocked, with a head «at 32» unscrew the nut securing the output shaft. To do this, you need to make an effort, since the nut is tightened with a large moment.

10. Lifting the driven gear of the 5th gear with screwdrivers (thereby compressing the synchronizer hub from the shaft), remove it together with the synchronizer and the fork from the secondary shaft.

Attention! Make sure that the synchronizer sleeve does not come off the hub, as the spring-loaded synchronizer locking balls may crumble.

11. Remove the thrust plate from the synchronizer. Then remove the fork from the groove of the synchronizer clutch.

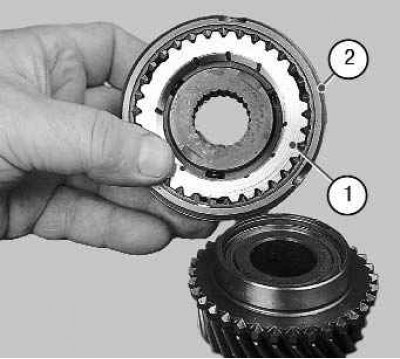

12. Remove the V gear from the synchronizer with blocking ring 1. Mark blocking ring 1 with respect to clutch 2 and remove it. During operation, the teeth of the ring are run in to the teeth of the coupling, therefore, during assembly, the ring must be installed in the same position. If you do not intend to disassemble the synchronizer, tie it with wire or rope so that it does not fall apart.

13. Remove the sleeve from the secondary shaft.

14. Remove the transmission drive gear from the input shaft. Notice how it's installed.

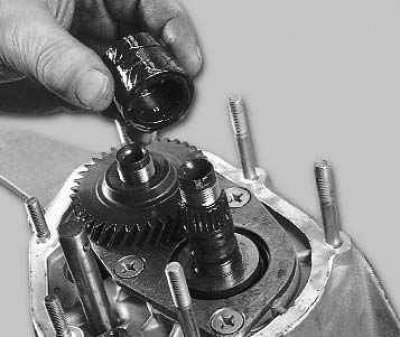

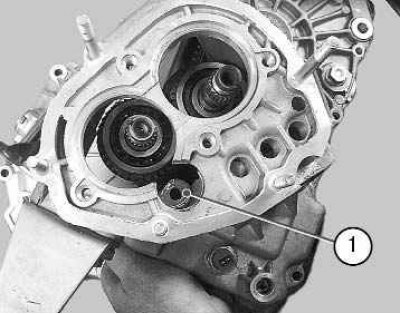

15. Using an impact screwdriver, remove the four screws (spring washers are installed under them) fixing the bearing plate and remove the bearing plate 1. Then remove the thrust washer 2 from the secondary shaft.

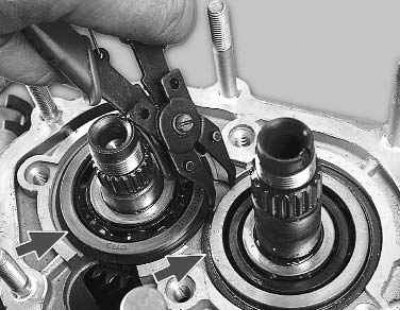

16. Remove the bearing circlips on both shafts by lifting the shafts by hand.

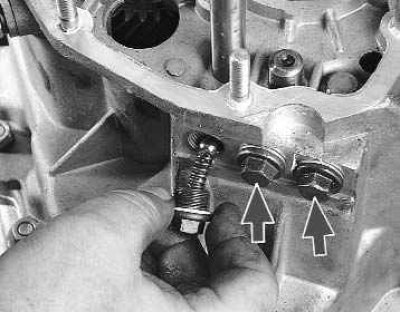

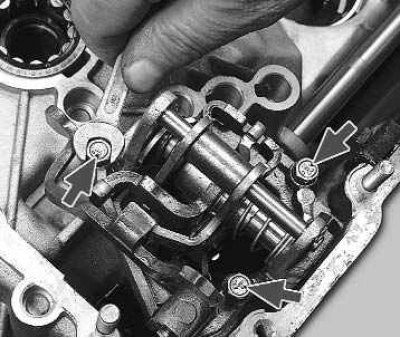

17. Key «at 13» unscrew the three stopper plugs and carefully remove the stopper balls with springs.

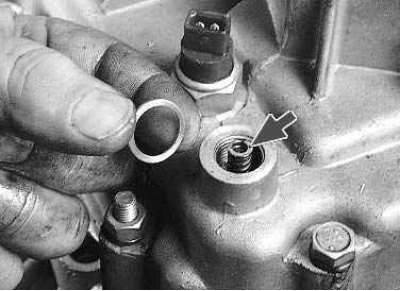

18. Having unscrewed a stopper of a clamp of a backing, remove a sealing ring, and then take a clamp spring.

19. Tilt the box and remove the lock ball.

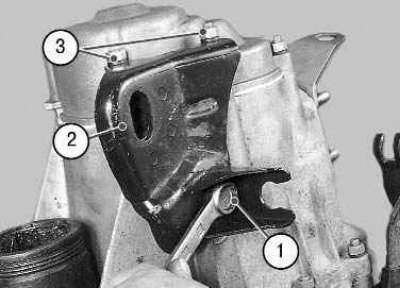

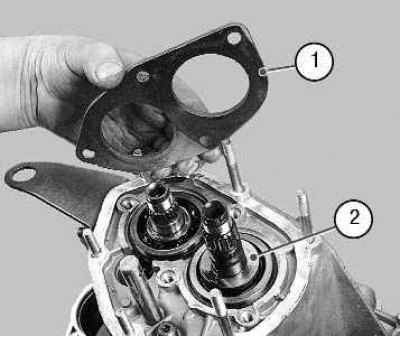

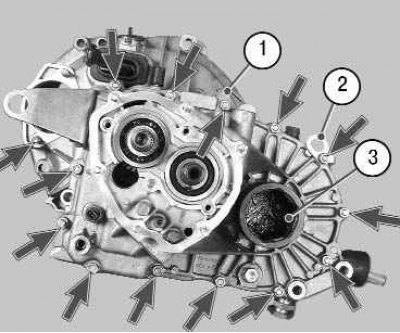

20. Turn away twelve nuts and turn out a bolt of fastening of cases of a transmission. Pay attention to under which nuts the holder 1 and transport eye 2 are installed. Spring washers are installed under the nuts and bolt. Remove plug 3 inserted instead of one of the drives.

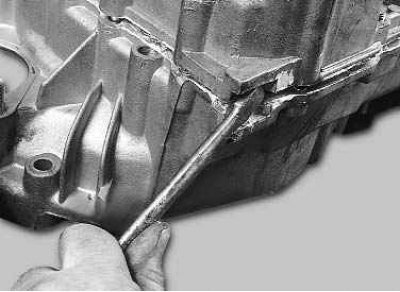

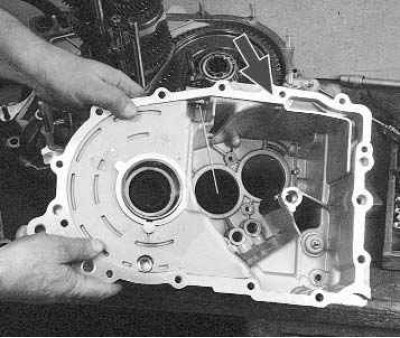

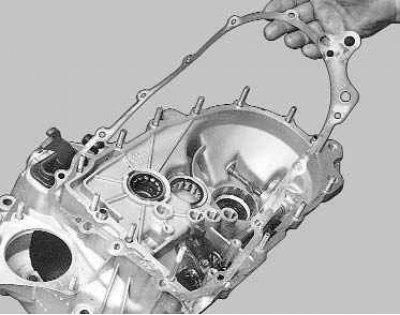

21. Inserting a screwdriver into the slots (three special grooves around the perimeter of the crankcases), separate the gearbox housing from the clutch housing.

22. Slightly lift the gearbox housing, turn it counterclockwise so that the tide 1 of the housing comes out from under the gear, and remove the gearbox housing from the clutch housing.

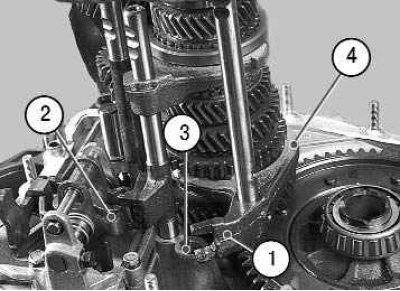

23. Key «on 10» Turn out bolts of fastening of plugs of switching of I and II, III and IV transfers.

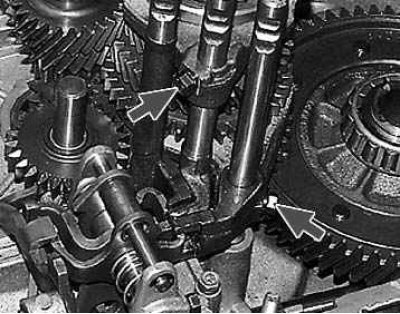

24. Slightly lift the shift rod of 1st and 2nd gears so that it comes out of support 3, and turn it counterclockwise so that the head 1 of the rod disengages from the locking bracket 2. Remove the plug 4 of the rod from the groove of the synchronizer coupling and remove the rod with the plug. Unless necessary, it is not recommended to remove the forks from the rods so as not to confuse them during assembly.

25. Turning the shift rod of III and IV gears, remove its head from engagement with the gear selection lever. Then lift the stem a little so that it comes out of the support, and, having removed the stem fork from the groove of the synchronizer coupling, remove the stem with the fork.

26. Turning the 5th gear engagement rod, disengage its head from the locking bracket. Remove the stem by removing it from the support.

27. Take out an axis of an intermediate gear wheel of a backing.

28. Slide the reverse intermediate gear all the way into the gear selection mechanism, turn it 30–40°and, removing it from under the shaft gears, remove the intermediate gear.

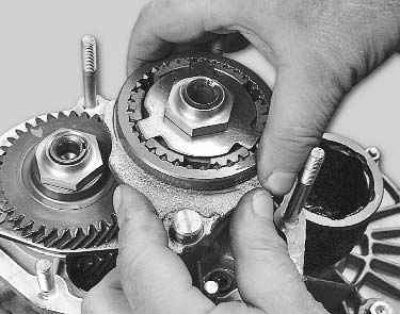

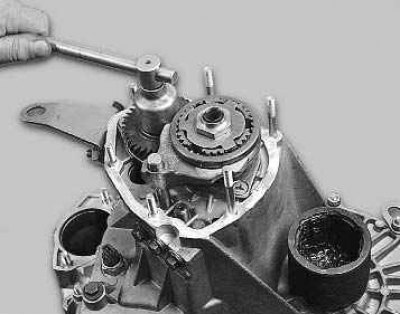

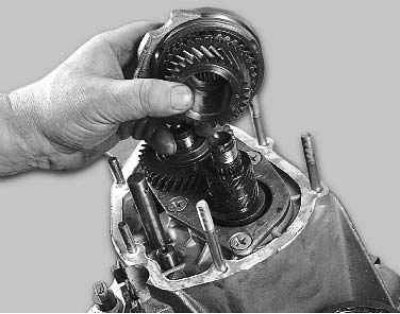

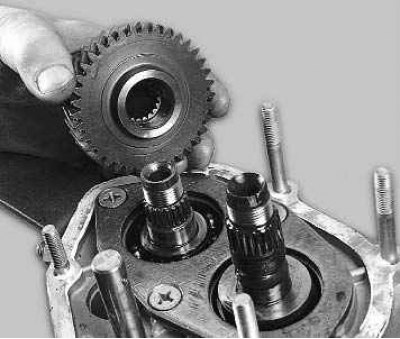

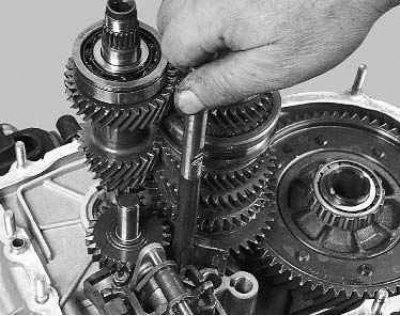

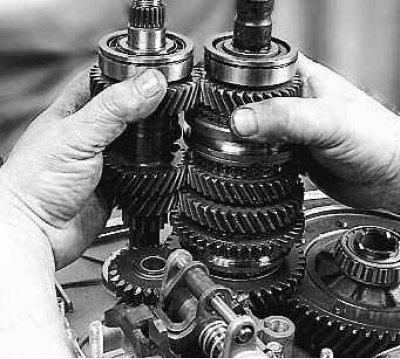

29. Slightly shaking, take out at the same time the primary and secondary shafts.

30. Remove the differential from the clutch housing.

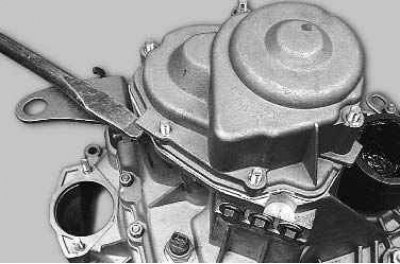

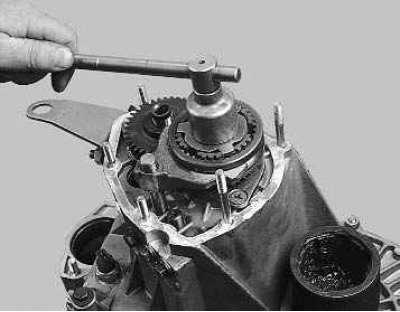

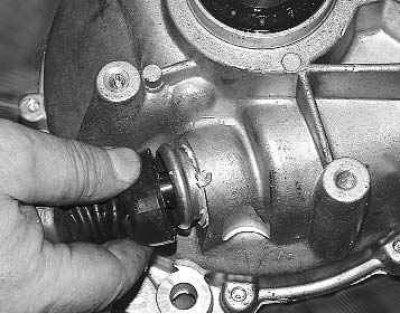

31. Key «on 10» unscrew the three bolts securing the gear selector mechanism (spring washers are installed under the bolt heads). Remove the gear selector.

32. Remove the magnet from the clutch housing.

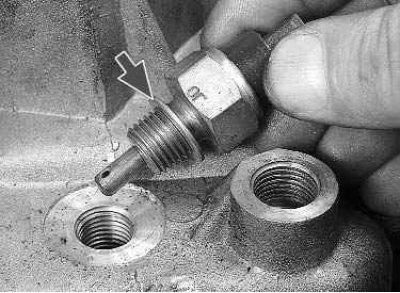

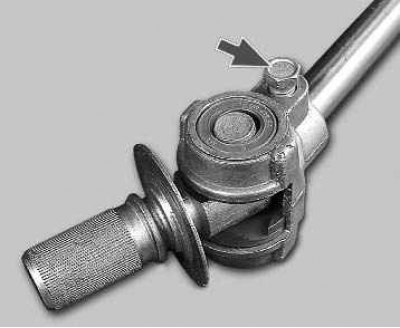

33. Key «on 10» Loosen the speed sensor mounting nut and remove the speed sensor.

34. Replace a torn or loose speed sensor o-ring.

35. Remove the reverse light switch from the gearbox housing. A metal sealing ring is installed under it.

36. There is a special puller for pressing the front bearing of the secondary shaft. If not, press out the bearing with a screwdriver.

37. Remove the oil collector installed under the bearing.

38. There is also a special puller for pressing out the input shaft front bearing. If it is not available, make a hook-shaped device out of hard wire. Insert the tool into one of the two slots in the crankcase and slide the hook under the bearing. Then with a screwdriver (placing a wooden block) press the bearing out of the crankcase by applying force to the opposite end of the screwdriver with hammer blows and alternately rearranging the hook in the grooves.

39. Press the new front shaft bearings all the way into the clutch housing using a suitable mandrel.

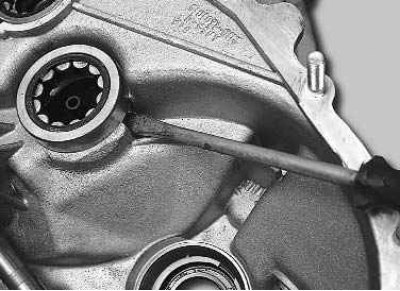

40. Use a screwdriver to pry off the lip of the selector rod protective boot and slide it off the rod support sleeve.

41. Key «on 10» Turn out a bolt 3 fastenings of the lever 2 of a choice of transfers. Sliding stem 1, remove the gear selector lever. Then remove the selector rod from the clutch housing.

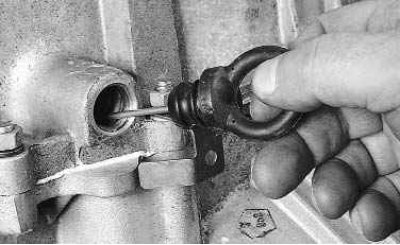

42. If it is necessary to replace the rod hinge, slide the protective cover off it and unscrew the hinge fastening bolt. The bolt is fixed with special glue TB-1324. Before screwing in the bolt, clean it of the old adhesive and apply a new one. Replace a torn or loose stem pivot boot.

43. To replace the clutch housing, remove the bearing from it (see «Replacing the clutch release bearing») and clutch release fork (see «Replacing the clutch release fork»), press out seals (see «Replacing gearbox seals»).

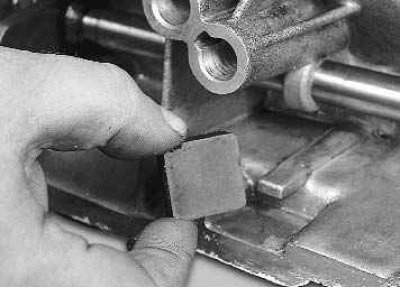

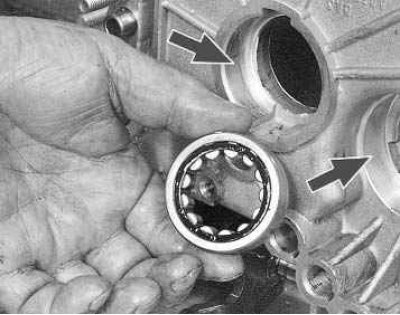

44. Inspect the clutch and gearbox housings, as well as the rear cover. They should not have cracks or chips. There should be no nicks, scratches, dents, etc. on the mating surfaces. Remove minor damage with sandpaper. If severely damaged, replace defective parts.

45. Check the bearing seats in the clutch and gearbox housings. These surfaces must not show signs of wear or damage. Otherwise, replace the crankcases.

46. Check the condition of the roller bearings. If the raceways, cage or rollers are damaged and play is detected (radial clearance in the bearing must not exceed 0.07 mm) replace the bearing.

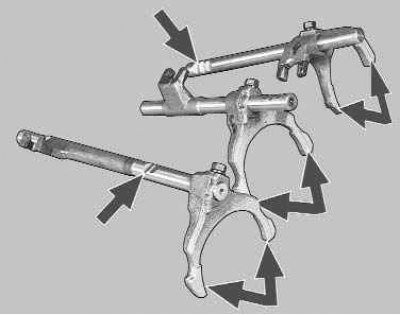

47. Check up a condition of rods of a gear change. Replace bent rods with scuffs, burrs or worn holes for retainers. Replace the forks if they are bent or their tabs are worn out.

48. Check the axle shaft seals. They should not be warped, have tears. The working edge must be even, without vyrovy, dents and rubber sagging. The gland spring must not be broken or stretched. Replace defective seals.

49. Check and, if necessary, replace the seals of the input shaft and gear selector rod (see «Replacing gearbox seals»).

50. Replace damaged or heavily compressed gaskets.

51. Clean the magnet of wear particles. If the magnet is cracked or magnetically weak, replace the magnet.

52. Thoroughly clean the mating surfaces of the clutch and gearbox housings, as well as the rear cover, from the old sealant.

53. Assemble the gearbox in the reverse order of disassembly, taking into account the following.

54. Before installing the shafts, engage the teeth of their gears and, in this position, install in the clutch housing.

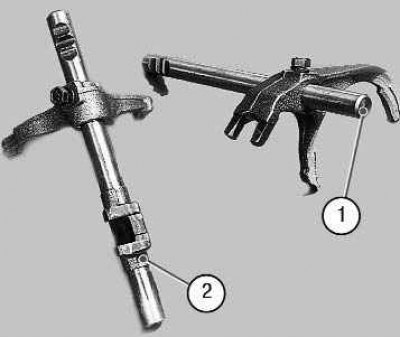

55. Pay attention to how the forks are installed on the gearshift rods: 1 - a rod with a shift fork of I and II gears, 2 - a rod with a shift fork of III and IV gears.

56. Copiously lubricate all friction parts with gear oil.

57. Don't forget to replace the magnet.

58. Before installing the gearbox housing on the clutch housing and rear cover, apply sealant to their mating surfaces around the entire perimeter.