Note. The inner CV joint seals can be replaced without removing the gearbox from the vehicle.

1. Disconnect the front wheel drives from the gearbox (see «Removal and installation of front wheel drives»).

Attention! Do not disconnect both drives at the same time, since in this case the gears of the axle shafts may shift in the differential and it will be impossible to install the drives without disassembling the gearbox. If both drives need to be disconnected, after disconnecting one of them, replace it with a process plug or the old inboard housing. Then disconnect the second drive.

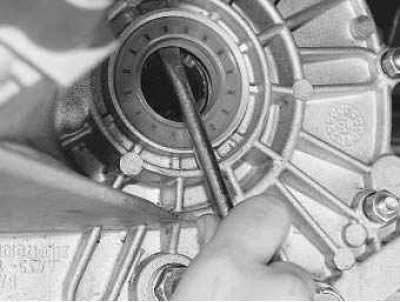

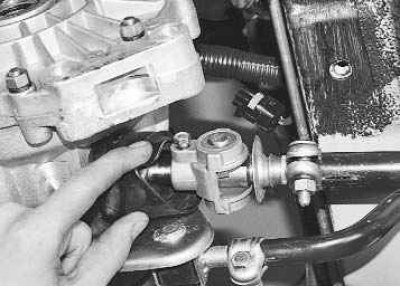

2. Use a screwdriver to remove the inner hinge seal from the crankcase.

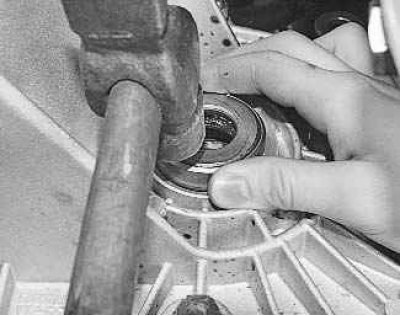

3. Press in a new oil seal with a suitable mandrel until it stops with the working edge inside the box.

Oil-squeezing notches at the seals of the right and left internal joints are directed in different directions.

Arrows and part numbers are marked on the oil seals for identification: on the right oil seal a (number det. 2110–2301034–01) arrow pointing counterclockwise, on the left gland b (number det. 2110–2301035–01) - clockwise. The arrows show the direction of wheel rotation as the vehicle moves forward.

4. Establish all removed details and knots in an order, the return to removal.

The reason for oiling the clutch discs may be a leak in the gearbox input shaft oil seal or the crankshaft rear oil seal.

Motor and transmission oils have different smells. Therefore, having a certain skill, it is possible to determine by smell which of the oil seals is defective: the input shaft oil seal or the crankshaft rear oil seal.

Note. There is another way to determine the type of oil. Drop the oil into the water poured into the vessel in a thin layer. Gear oil will spread over the entire surface of the water in the form of an iridescent film, and engine oil will remain in the form of a drop similar to a lentil grain.

To replace the input shaft seal you need to remove the gearbox from the car (see «Removal and installation of a transmission»).

You will need: the same tools as for replacing the clutch release bearing (see «Replacing the clutch release bearing»), as well as the key «on 10», screwdriver.

1. Remove the clutch release bearing (see «Replacing the clutch release bearing»).

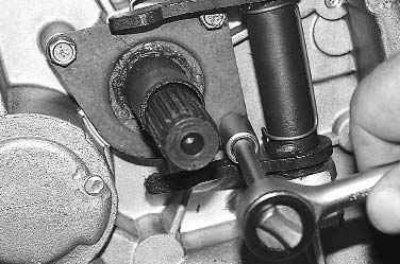

2. Turn out three bolts of fastening of the directing plug. Remove the guide bush.

3. Use a thin wire hook or screwdriver to pry out the oil seal. Press in a new oil seal using a suitable mandrel. The working edge of the stuffing box must be directed inside the gearbox.

4. Install the removed parts in the reverse order of removal.

Shift rod oil seal can be replaced directly on the vehicle.

You will need: key «on 10», a thin chisel, a hammer, a mandrel for pressing the stuffing box.

1. Remove the mudguard from the hinge and slide it over the shift shaft.

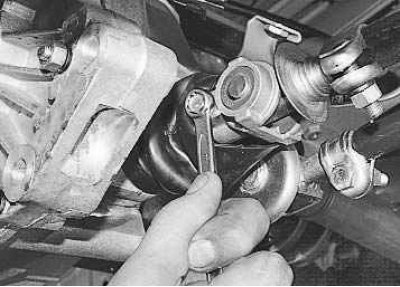

2. Turn out a bolt of fastening of the hinge to a gear shift rod...

3.... and disconnect the gear selection rod together with the hinge from the rod.

Note. The hinge-to-stem bolt is different in length and color from similar bolts used in the gearbox to attach the forks and gear lever. This bolt is cadmium (golden color coating), other bolts are phosphated (dark color coating). Do not replace this bolt with others.

Note. Bolt with damaged tapered shank or thread Replace.

Note. The bolt is fixed with special glue TB-1324. Before screwing in the bolt, clean it of old glue, degrease the threaded part and apply new glue. If special adhesive is not available, use a commercially available anaerobic thread locker.

4. Remove the dirt cover.

Note. Replace a torn or cracked dust cover.

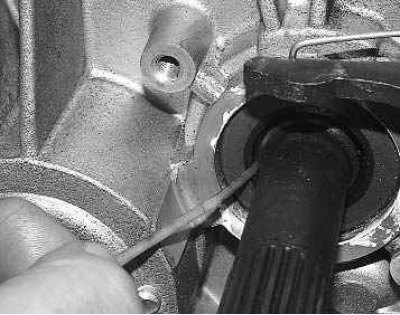

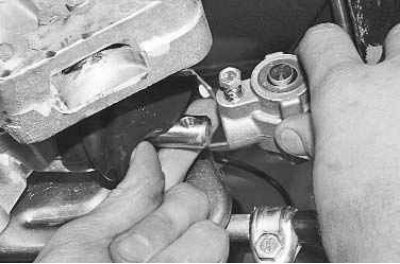

5. Having rested the chisel on the shoulder of the stem seal holder, with gentle blows of the hammer, press the holder out of the gearbox housing...

6.... and remove it from the stem assembly with the stuffing box.

7. Using a suitable mandrel (you can use the head from the tool kit) press out...

8.... and remove the stuffing box from the cage.

9. Press the new oil seal into the cage until it stops with the working edge inside the gearbox.

10. Lubricate the sealing lip with gear oil and with light blows of a hammer, press the cage together with the seal into the gearbox housing until it stops.

11. Establish all removed details and knots in an order, the return to removal.