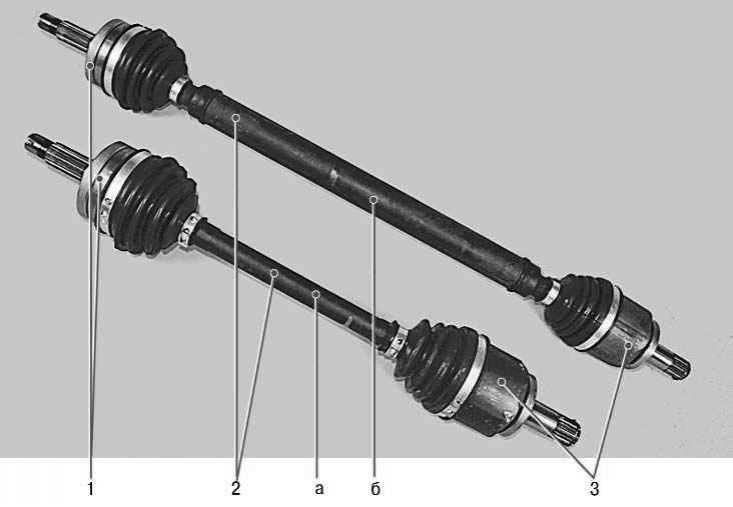

Pic. 6.12. Front wheel drives: a – left front wheel drive; b – right front wheel drive; 1 - external hinges; 2 - front wheel drive shafts; 3 - internal hinges

Front wheel drives consist of external 1 (pic. 6.12) and internal 3 constant velocity joints (SHRUS), connected by shafts 2. The external hinge allows only angular movements of the connected shafts. The internal hinge, in addition to the angular ones, also provides axial displacement of the shafts when the front wheels are turned and the suspension is working. The left wheel drive shaft is made of a bar, and the right one is made of a pipe. In addition, the drive shafts differ in length: the right one is longer than the left one.

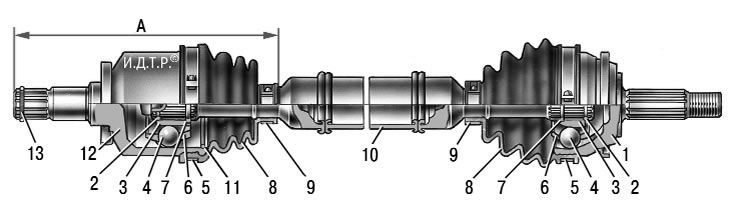

Pic. 6.13. Front wheel drive: 1 - body of the outer hinge; 2 - retaining ring; 3 - clip; 4 - ball; 5 - outer collar; 6 - separator; 7 - thrust ring; 8 - protective cover; 9 - inner collar; 10 - wheel drive shaft; 11 - retainer of the internal hinge; 12 - body of the internal hinge; 13 – a lock ring of the case of the internal hinge; A - control size

The outer hinge consists of a body 1 (pic. 6.13), separator 6, inner cage 3 and six balls. Grooves are made in the hinge body and in the holder to accommodate the balls. The grooves in the longitudinal plane are made along the radius, which provides an angle of rotation of the outer hinge up to 42°. The slotted tip of the hinge housing is installed in the front wheel hub and is attached to it with a nut.

The holder 3 of the hinge is mounted on the splines of the shaft 10 between the thrust ring 7 and the retaining ring 2.

The inner hinge differs from the outer one in that the paths of the body and the clip are straight rather than radial, which allows the hinge parts to move in the longitudinal direction. This is necessary to compensate for movements caused by oscillations of the front suspension and power unit.

Balls of the same sorting group are installed in the outer and inner hinges, if necessary, all six hinge balls are replaced; balls must be of the same sorting group. When assembling the inner hinge, a selective method is used. Replacement of any one part is not allowed - the inner joint must be replaced as an assembly.

Hinge parts are lubricated with SHRUS-4 grease, which is put into the hinge housings during assembly. Sealing of hinges is provided by the protective covers fixed by collars.

Note. The drive hinges are very durable, their design life is almost equal to the life of the car. However, in operation they are changed or repaired quite often. This work is expensive and labor intensive. In order to save a lot of money, regularly check the condition of the protective covers of the hinges and immediately replace them at the slightest damage. If water or dust gets into the hinge through a damaged cover, it will fail after several hundred kilometers. The sealed hinge wears out extremely slowly.