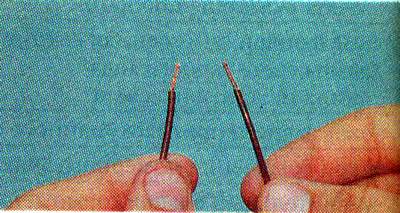

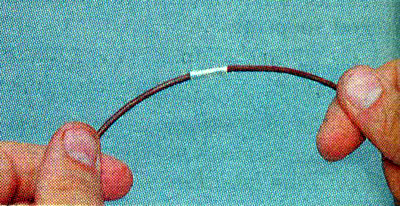

1. We clean the ends of the wires to be connected so that the stripped part is equal in length to half the coupling.

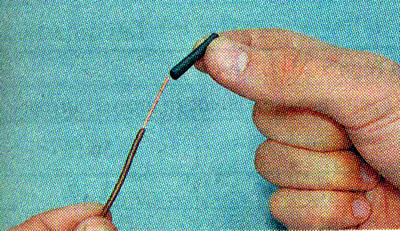

2. We put on one of the wires a heat-shrinkable tube with a length of approximately 10 mm more than the coupling.

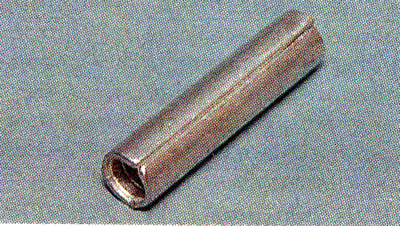

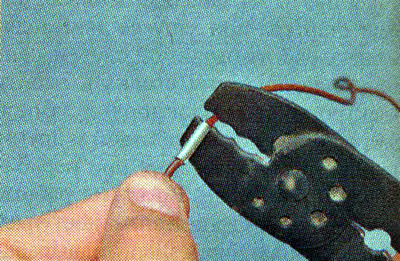

3. Insert the ends of the wires into the connector.

4. We crimp the coupling with special pliers.

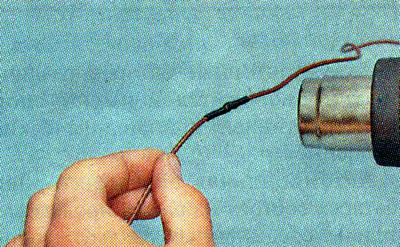

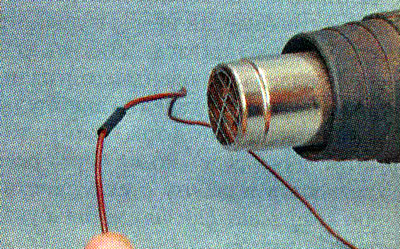

Warning! When performing the following operation, do not bring the heat gun too close to the heat deposit tube as it may melt.

5. We shift the heat-setting tube onto the coupling and evenly heat it with a heat gun.

In the absence of a coupling, the wires can be connected by twisting.

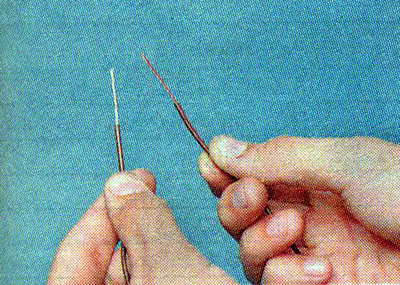

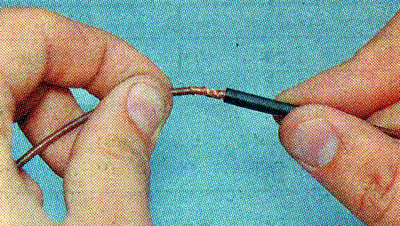

1. We clean the connected wires by about 20-25 mm.

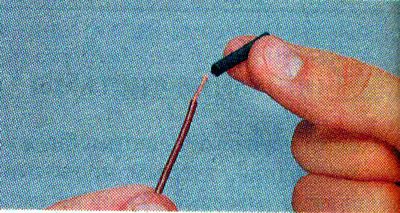

2. We put on one of the wires a heat-setting tube about 25 mm long.

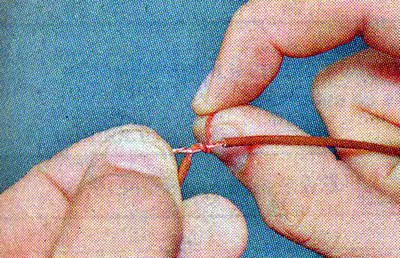

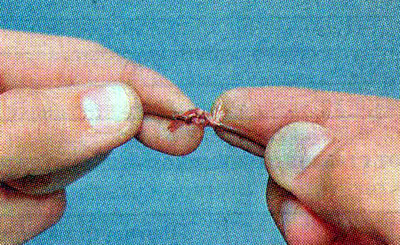

3. We cross the wires and wrap the first wire one turn with the second.

4. We perform a similar operation with the second wire.

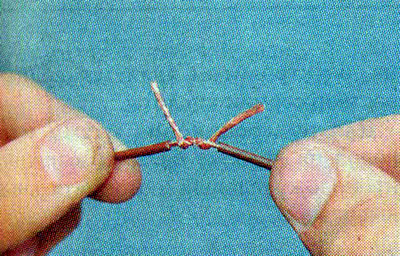

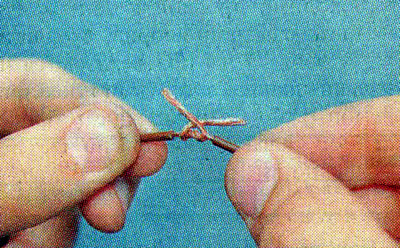

5. We cross the ends of the wires.

6. Tightly twist the ends around the wires.

7. We shift the heat-setting tube to the twist.

Warning! When performing the following operation, do not bring the heat gun too close to the heat deposit tube as it may melt.

8. Evenly heat the heat-setting tube with a heat gun.