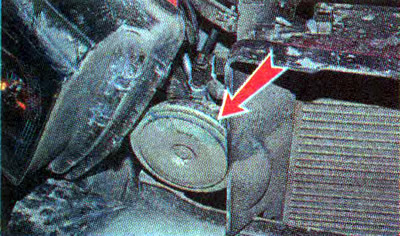

Comment. An audible alarm is installed in the engine compartment on the left side.

The horn plays an important role in road safety. Therefore, any malfunction in its operation must be identified and eliminated as soon as possible. If the volume has decreased or the tone of the sound signal has changed, there is no need to immediately check its electrical circuit. In this case, most likely, the dirt and reagents with which the roads are treated have disabled it.

But if the sound signal completely stopped working, then most likely the reason is not in itself.

To perform the work, you will need an assistant, two pieces of wire about half a meter long (one with a built-in 10 A fuse) and multimeter.

Execution sequence

1. We prepare the car for work (see «Preparing the car for maintenance and repair»).

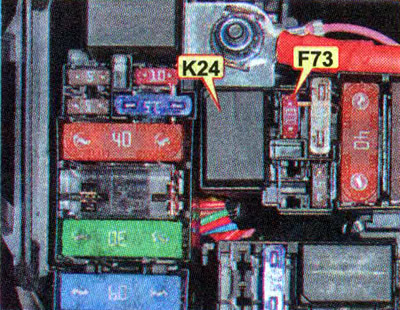

2. We check the health of the fuse F73 10 A and relay K24 in the fuse and relay box in the engine compartment (see «Mounting block - location of fuses and relays»).

We replace a defective relay or a blown fuse. If the fuse blows again, look for a short circuit in the electrical circuit (see «Checking and repairing electrical circuits»).

3. If the fuse and relay are OK, remove the front bumper cover (see «Front bumper - removal and installation»).

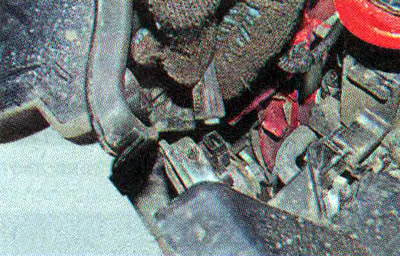

4. Disconnect the block of the wiring harness from the conclusions of the sound signal.

5. Check the connector for dirt and oxides. If necessary, clean it with a special electrical contact cleaner.

6. We connect the probes of the multimeter, turned on in the voltage measurement mode, to the connector pins and measure the voltage while the horn switch is pressed. The multimeter should show battery voltage.

If there is no voltage, check the electrical circuit.

7. To check the sound signal for a short circuit, connect one of its outputs to «weight», the second piece of wire with a 10 A fuse embedded in it is briefly connected to the positive terminal of the battery.

If the fuse blows, the horn has a short circuit and needs to be replaced. If it runs quietly, it also needs to be replaced.

Recommendation. An adjusting screw is made on the inside of the horn and a slotted screwdriver with a thin blade can be used to adjust the sound of the signal. If the sound is hoarse and weak, and it is not possible to achieve an acceptable sound by turning the adjusting screw, the sound signal must be replaced.

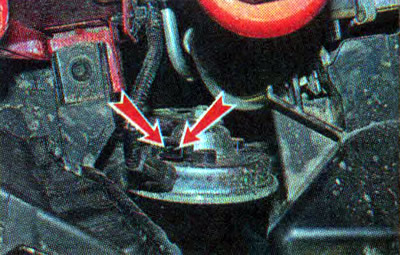

8. Using a 13 mm wrench, unscrew the nut that secures the sound signal and remove it.

9. Set the sound signal in reverse order. After installation, we check the operation of the sound signal.