...and to the left of the engine compartment.

The left support is attached to the side member with four bolts. The support is attached to the gearbox bracket with two bolts. The bracket itself is fixed to the gearbox housing with three bolts. Access to the left support is closed by the battery shelf.

To reduce vibrations of the power unit during engine operation and while the vehicle is moving over bumps, a rear support is additionally installed from below. It is a rod that connects the gearbox to the subframe.

A malfunction of one or more supports may be indicated by increased vibration, knocking with an increase in engine load (at the moment of start or sharp acceleration of the car). Supports are not subject to repair and in case of failure they are replaced.

The condition of the rear support can be checked by swinging it with a mounting blade in the longitudinal and transverse directions.

The technical condition of the supports can be assessed visually. When checking, it is especially necessary to carefully examine the rubber elements of the supports.

Supports are subject to replacement, the rubber of which has gaps, cracks or is severely deformed.

It is also necessary to replace the support that has fatigue cracks in the metal elements.

Warning! When replacing the supports, care must be taken, since the work is associated with hanging the power unit.

Replacing the right support

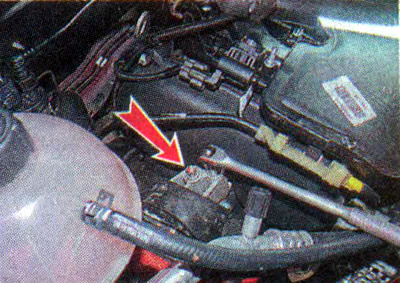

The need for replacement is determined during the check of the technical condition of the engine (see «Engine - condition check»). The right support is attached to the side member with two bolts, and three bolts to the engine.

To perform the work, you will need a stand, adjustable in height or a jack.

1. We install the car on a viewing ditch or overpass (see «Preparing the car for maintenance and repair»).

2. Remove the engine mudguard (see «Mudguard of the engine - removal and installation»).

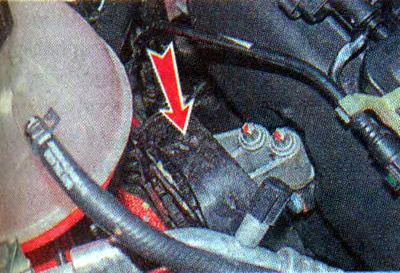

3. We install a jack under the right side of the engine. Having slightly raised the engine on the jack, we unload the right support of the power unit.

4. Using a 16 mm socket wrench, unscrew the two bolts securing the support to the body.

5. We slightly raise the right side of the engine on the jack so that the right support rises above the side member.

6. Using a TORX E12 socket wrench, unscrew the two bolts securing the support to the engine bracket.

7. Remove the support.

8. Install a new support in reverse order. We tighten the support mounting bolts with a torque of 53-71 Nm.

Replacing the left support

The need for replacement is determined during the check of the technical condition of the engine (see «Engine - condition check»).

To perform the work, you will need a stand, adjustable in height or a jack.

1. We prepare the car for work (see «Preparing the car for maintenance and repair»).

2. Remove the engine mudguard (see «Engine crankcase mudguard - removal and installation»).

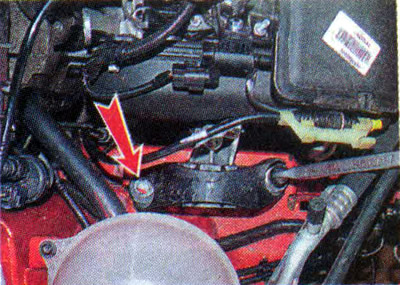

3. Install a stand or jack under the gearbox. Having slightly raised the gearbox on the jack, we unload the left support of the power unit.

4. Remove the battery (see «Battery - removal and installation»).

5. Squeezing the latches, release the three wire harness holders by removing them from the holes in the battery shelf.

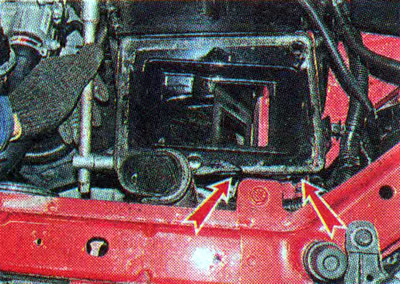

6. Under the shelf with a 10 mm socket wrench with an extension, unscrew the four bolts securing the shelf to the body side member (they are not visible in the photo).

7. Remove the battery shelf.

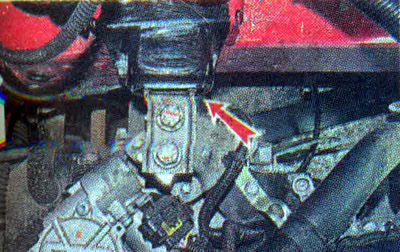

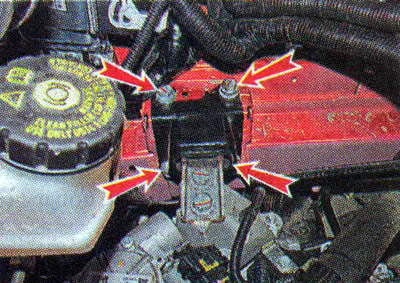

8. Using a 16 mm key, unscrew the four bolts securing the right support to the body.

9. On the jack, slightly raise the left side of the power unit so that the left support no longer rests on the body side member.

10. Using an 18 mm wrench, unscrew the two bolts securing the support to the gearbox bracket.

11. Remove the left support.

12. Install a new support in reverse order. We tighten the bolts of the support to the gearbox bracket with a torque of 90-120 Nm. We tighten the bolts of the support to the body with a torque of 53-71 Nm. We tighten the bolts of the battery shelf with a torque of 10 Nm.

Replacing the rear support

The need for replacement is determined during the check of the technical condition of the engine (see «Engine - condition check»).

To perform the work, an inspection ditch or overpass is required.

1. We prepare the car for work (see «Preparing the car for maintenance and repair»).

2. Remove the engine mudguard (see «Mudguard of the engine - removal and installation»),

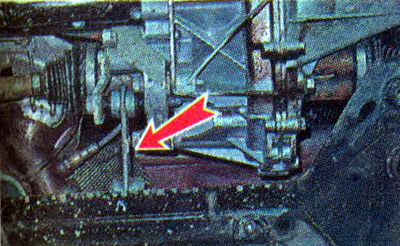

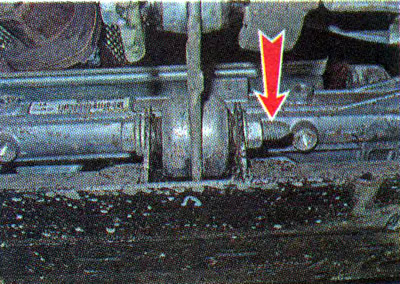

3. We process the threaded part of the bolt of the rear support of the power unit with a penetrating liquid.

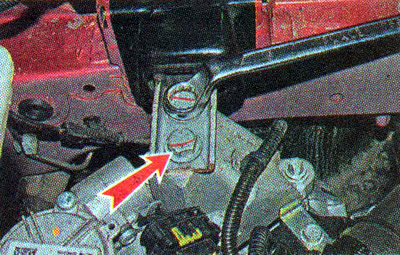

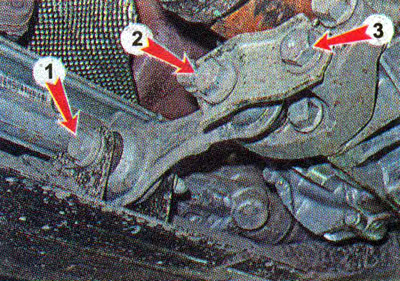

4. Using an 18 mm spanner wrench, unscrew the nut of bolt 1 securing the rear support to the subframe, holding the bolt from rotation with a wrench of the same size. Using an 18 mm wrench, unscrew the bolt 2 securing the support to the gearbox bracket. Using the same wrench, we loosen the tightening of the bolt 3 of the fastening of the rear support bolt bar.

5. Remove the rear support bolt.

6. Remove the rear support.

7. Install! support in reverse order. We tighten the fastening bolts with a torque of 90-120 Nm.