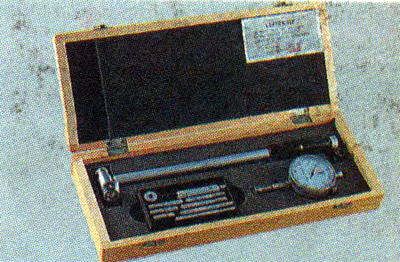

To do the job, you will need a bore gauge and a piston ring mandrel.

Disassembly

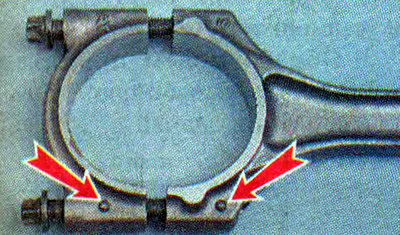

1. Remove the piston rings from the piston (see «Piston rings and connecting rod bearings - replacement»).

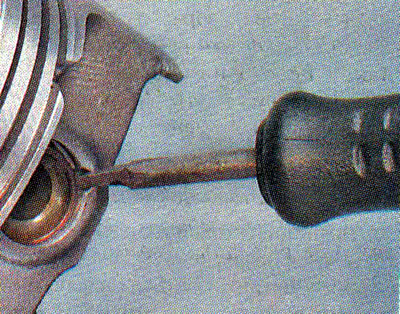

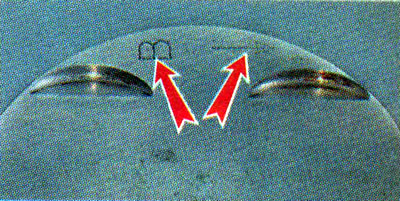

2. With an awl or a screwdriver with a thin blade, pry off and remove the piston pin lock ring from the groove.

Recommendation. If the grooves of the retaining rings are jammed, in the nicks and the rings in them are not securely fixed, the piston should be replaced.

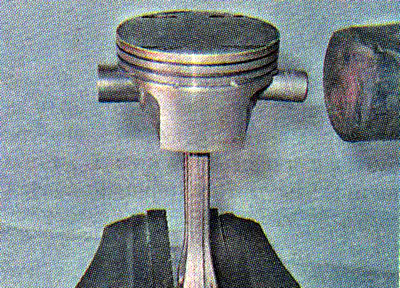

3. With a bar of soft metal with a diameter of 16-18 mm, we push out the piston pin and remove the piston from the connecting rod.

Examination

In new engines, the clearance between the piston and the cylinder is 0.025–0.045 mm and is set by installing pistons of the same class as the cylinders. The class of the piston and cylinder are indicated by Latin letters, which are knocked out on the lower mating surface of the cylinder block...

...and on the bottom of the piston. The arrow on the piston points towards the front end of the crankshaft.

Comment. For how to use the caliper, see the enclosed instructions or specialist literature.

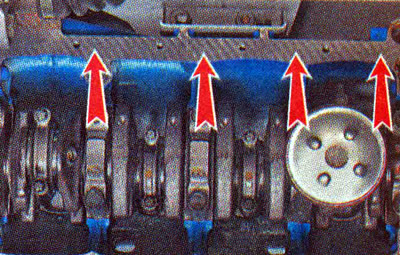

1. With a bore gauge, we check the wear of the cylinder walls.

Measurements are carried out in four belts (3, 10, 60 and 112 mm from the top edge of the cylinder) in the longitudinal and transverse directions of the engine. In the upper belt, the cylinder does not wear out. By the difference in readings of the caliper in different belts, we determine the degree of wear of each cylinder.

2. Having measured the diameter of the piston skirt with a micrometer, we determine its wear.

If the maximum wear is 0.7 5 mm or more, it is necessary to bore the cylinders and install oversized pistons, or replace the cylinder block and install new pistons.

For new engines, the clearance between the piston and the cylinder is 0.025-0.045 mm and is set by installing pistons of the same class as the class of cylinders.

Assembly

We assemble the piston with the connecting rod in the reverse order of disassembly. In this case, the arrow on the bottom of the piston and the marks on the connecting rod and its cover must be facing the same direction.