Examination

1. We prepare the car for work (see «Preparing the car for maintenance and repair»).

2. Remove the engine trim (see «Decorative overlay of the engine - removal and installation»).

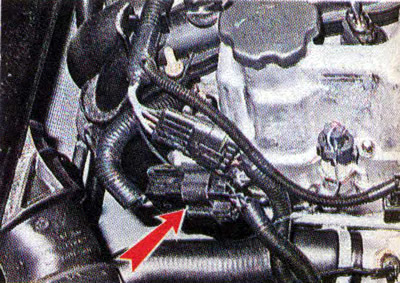

3. Disconnect the injector wiring harness pads.

4. Turning on the ignition, use a voltmeter to measure the voltage at the supply terminal 3 of the block of the wiring harness of the control system, which must be at least 12 V (conclusions are indicated by letters on the block, «negative» The instrument probe must be connected to «mass» engine).

Warning! Turn off the ignition after the voltage measurement is completed.

Comment. If the voltage is not supplied to the block or it is less than 12 V, then the battery is discharged, the power circuit is faulty, or the computer is faulty.

5. We check the electrical resistance of the injectors, for which we measure the resistance between terminal 3 and the remaining four terminals of the injector wiring harness block and knock sensors and camshaft position with an ohmmeter. The output of the block, indicated by the number 8, corresponds to the injector of the first cylinder, and the conclusions 7, 2 and 1 correspond to the injectors of the second, third and fourth cylinders, respectively. In serviceable injectors, the resistance should be 13 ohms.

6. Using two wires directly from the battery, we supply 12 V voltage to the terminals of block 2 - we connect terminal 3 to the positive terminal of the battery, and terminals 8, 7, 2 and 1 in series with the negative terminal of the battery. With a working nozzle, a characteristic click should be heard when the valve is opened.

7. We replace defective nozzles.

Removing

1. Remove the fuel rail (see «Fuel rail - removal and installation»).

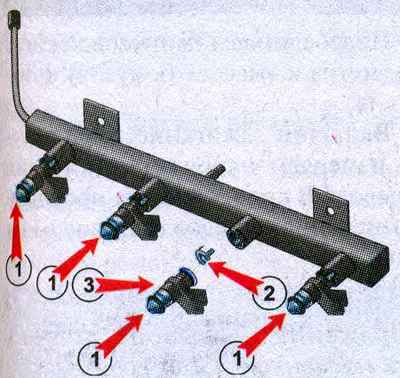

2. By external inspection, we check the condition of the spray nozzles 1.

3. Remove the nozzle holder 2. Remove nozzle 3 from the fuel rail.

Recommendation. Nozzles with clogged nozzles should also be replaced, as should nozzles with defective coils.

4. We take out the nozzle from the ramp.

5. Similarly, remove the three remaining nozzles.

Installation

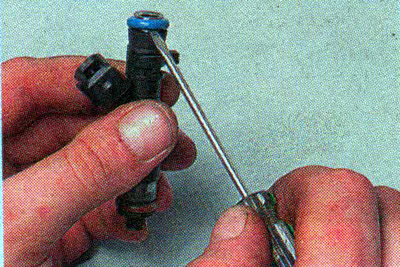

Comment. The manufacturer recommends replacing the O-rings.

New nozzles come to spare parts, as a rule, already with seals. In the event that the injectors have to be removed not for replacement (e.g. when performing other repair work), then before installation it is necessary to purchase new sealing rings.

1. Install new o-rings on the injectors. Before installation, wipe the nozzle sealing rings with engine oil.

2. Install the nozzles in reverse order.