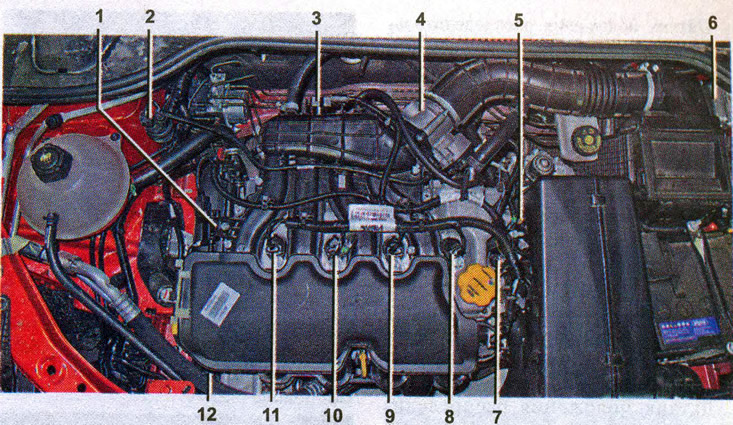

Location of elements of the engine management system 21129: 1 - solenoid valve of the system for changing the length of the channels of the intake pipeline; 2 - adsorber purge valve; 3 - absolute pressure and air temperature sensor in the intake manifold; 4 - throttle assembly; 5 - coolant temperature sensor; 6 - electronic engine control unit (ECU); 7 - emergency oil pressure sensor; 8 - ignition coil of the fourth cylinder; 9 - ignition coil of the third cylinder; 10 - ignition coil of the second cylinder; 11 - ignition coil of the first cylinder; 12 - location of the camshaft position sensor

The engine management system turns the fuel pump on and off, controls the amount of air entering the engine cylinders, injects the required amount of fuel into the intake manifold, controls sparking at the spark plugs, corrects the ignition timing, adjusts the idle speed of the crankshaft, controls the electric fan of the cooling system engine.

Engine management system - electronic, with distributed phased fuel injection (i.e. fuel is injected into the intake manifold of each cylinder according to the engine duty cycle). The system consists of the following elements:

- electronic control unit;

- sensors:

- 1) crankshaft position sensor;

- 2) camshaft position sensor;

- 3) throttle position sensor (built into throttle body);

- 4) knock sensor;

- 5) coolant temperature sensor;

- 6) absolute pressure and air temperature sensor in the intake manifold;

- 7) two oxygen concentration sensors;

- 8) electronic gas pedal (gas pedal position sensor);

- 9) brake pedal position sensor;

- 10) clutch pedal position sensor

- 11) air conditioning pressure sensor;

- executive devices:

- 1) main relay;

- 2) fuel pump relay;

- 3) nozzles;

- 4) ignition coils;

- 5) cooling fan relay;

- 6) electric throttle (built into throttle body);

- 7) solenoid valve of the system for changing the length of the intake manifold channels;

- 8) engine malfunction indicator lamp;

- 9) adsorber purge valve;

- connecting wires;

- diagnostic socket.

The engine management system is also integrated:

- speedometer;

- tachometer.

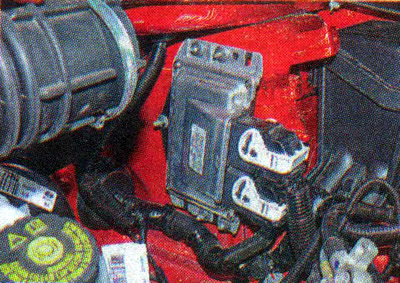

The main control element of the system is the electronic control unit (ECU), or, as it is often called, a controller with an integrated microprocessor. In fact, an ECU is a specialized mini-computer in which only one program is installed - engine control, and sensors and actuators form the peripheral equipment of this computer, the unit receives and analyzes sensor signals. Based on the received data, the block calculates control commands and issues them to the actuators. The unit has three types of memory*: ROM (ROM), random access memory (RAM) and flash memory (PROM).

ROM - non-volatile memory (that is, the information in the memory is retained when the power is turned off) and is a microchip («chip») *. The ROM stores the calculation program and the data necessary for the calculation (engine parameters, transmission ratios and other characteristics). This information is individual for each vehicle modification.

* The design of the ECU is subject to change by the manufacturer.

Warning! Unqualified reprogramming of the ROM can lead to malfunctions in the engine, failure of the elements of the engine control system, and damage to the engine.

During operation, the ECU monitors the health of all elements and circuits of the engine management system. Having detected a malfunction, the ECU puts the engine management system into standby mode and turns on the engine malfunction indicator lamp on the instrument panel. The engine will then be able to continue running (except in the case of a malfunction of the crankshaft position sensor, see below), which allows you to get to the place of repair on your own. The ECU writes the codes of the detected faults to the RAM. It also stores operational information that the ECU microprocessor uses in calculations. When the battery is disconnected from the vehicle's on-board network, all information stored in RAM will be deleted.

The EEPROM stores codes for the car's anti-theft system (immobilizer). This type of memory is non-volatile. After activating the immobilizer, the ECU blocks the operation of the engine management system when trying to start the engine without special electronic keys.

Electronic control unit (ECU)

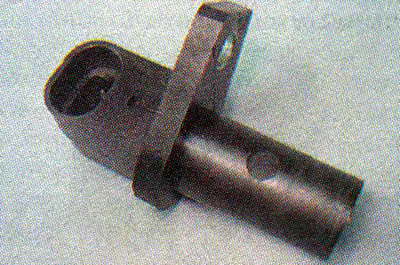

crankshaft position sensor (DPKV) is designed to generate signals by which the ECU synchronizes its work with the cycles of the engine's working process. Therefore, often this sensor is called a synchronization sensor. The operation of the sensor is based on the principle of induction - when the teeth of the crankshaft pulley pass by the sensor core, alternating current voltage pulses occur in the sensor circuit.

The frequency of appearance of pulses corresponds to the frequency of rotation of the crankshaft. The teeth are located around the circumference of the pulley (after 6°). Two of them are separated from each other at an angular distance of 18°. This was done to form reference signals in the sensor circuit - original reference points, relative to which the ECU determines the position of the crankshaft - top dead centers in the first / fourth and second / third cylinders. Engine operation with a faulty crankshaft position sensor is not possible. The crankshaft position sensor cannot be repaired - in the event of a malfunction, it is replaced as an assembly.

crankshaft position sensor

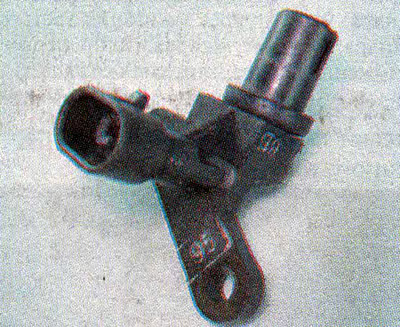

Camshaft position sensor (DPRV) designed to generate a signal by which the ECU determines the top dead center (TDC) piston of the first cylinder during the compression stroke. Sometimes this sensor is called a phase sensor. The principle of operation of the sensor is based on the Hall effect. When the protrusion of the ring attached to the intake camshaft pulley passes through the slot in the end of the sensor, the sensor sends an electrical signal to the computer. In the event of a malfunction of the DPRV, the electronic control unit switches the system to a standby mode of operation.

The camshaft position sensor is an electronic device that cannot be repaired. If the sensor is defective, it must be replaced.

Camshaft position sensor

DPRV is installed in the rear protective cover of the timing belt (under the intake pan above the generator)

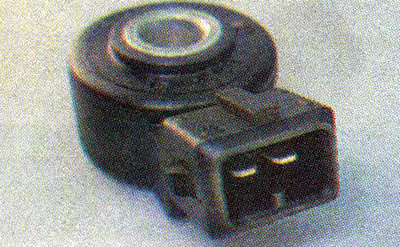

Knock sensor (DD) - piezoelectric, responds to engine vibration. Based on the signals from the sensor, the ECU determines the moment of detonation when the engine is running and, in accordance with this, corrects the ignition timing. In the event of a malfunction of the DD, the electronic control unit switches the system to a backup mode of operation.

Knock sensor

The knock sensor is mounted on the front wall of the cylinder block

The absolute pressure and air temperature sensor in the intake manifold is installed on the intake manifold from above.

To measure the pressure in the sensor, a piezoelectric element is used, the signal of which changes in proportion to the pressure in the inlet pipeline. Based on the signal from the sensor, the ECU calculates the amount of air entering the engine cylinders. In the event of a sensor malfunction, the ECU switches the system to standby mode and turns on the malfunction lamp on the instrument panel.

The amount of air entering the engine cylinders is regulated by the throttle assembly, which is installed between the intake manifold receiver and the air filter.

In order for the engine to meet more stringent environmental standards, the throttle actuator is equipped with a geared motor. The gas pedal is electronic, it has no mechanical connection with the throttle. Engine management is fully electronic. In fact, the driver, by pressing the gas pedal, only indicates what acceleration he would like to give the car, and the engine management system implements this. The same happens when the driver loosens the pressure on the gas pedal, keeps it pressed in one position, or completely removes his foot from the gas pedal. Such a system at AvtoVAZ is called «E-gas» (E-GAS). Engines with such a system can comply with Euro 5-6 environmental standards.

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body.

Throttle assembly

When starting and warming up the engine, as well as in idle mode, the air flow into the cylinders is controlled by opening the throttle.

The throttle position is monitored by two sensors built into the throttle body.

The throttle opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that must enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling and so on), ambient air and engine temperature, gas pedal position.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU controls the opening angle of the damper and, if necessary, issues appropriate commands to correct its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimum composition of the combustible mixture is maintained in any engine operating mode.

The throttle body with electric throttle is sensitive to deposits that can accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle, wedging it (especially at small opening angles). As a result, the engine will work unstably and even stall at idle, start poorly, and dips may appear in transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compositions when performing the next maintenance of the car. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the functionality of the throttle assembly, then it must be replaced.

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the connecting block of the wiring harness). In this case, it will be possible to restore work by treating the conclusions with a special composition for cleaning and protecting electrical contacts. There may be other reasons for the failure:

- the throttle assembly does not receive supply voltage;

- signals are not received from both throttle position sensors;

- The ECU cannot recognize the signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode. At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place (pull over, leave the intersection, etc).

The fact that the throttle assembly is operating in emergency mode may be indicated by a lit warning lamp for a malfunction of the engine management system and an increased idle speed of the crankshaft (about 1500 min-1, despite the fact that the engine is warmed up to operating temperature). The engine will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer. During operation, there is a gradual wear of the conductive tracks and moving contacts. Over time, wear can reach such an extent that the correct operation of the sensor becomes impossible. The presence of two sensors increases the reliability of the entire assembly.

If only one sensor fails, the control lamp will light up, but the engine management system will switch to the standby mode. In this case, the engine will adequately respond to pressing the gas pedal, but with worse operating parameters.

Standby mode allows you to drive your car to the place of repair on your own.

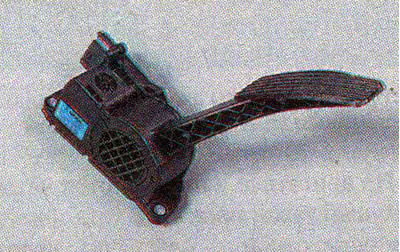

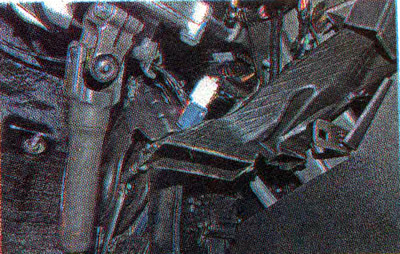

The electronic gas pedal consists of a plastic lever, which is integral with the pedal, and two sensors built into the bracket. All elements are a single design, which is sometimes called the gas pedal module.

Each pedal position sensor (built into the gas pedal bracket) is a potentiometer, the movable contact of which is rigidly connected to the rotary axis of the pedal lever. Electronic control unit (ECU) according to the signals of the sensors continuously monitors the position of the pedal. The change in position is controlled by the changing resistance at the outputs of both sensors. In accordance with these parameters, the ECU sends control commands to the throttle assembly motor-reducer and to the fuel injectors. As a result of wear of the moving contacts or conductive tracks, the sensors may fail or the signals coming from them will not be correct. If the signals are disturbed, the engine will run erratically, possible «failures» in transitional modes. When idling, the engine speed may spontaneously change.

In case of failure of one of the sensors (or his chains), the engine control system malfunction indicator lamp will come on. If during the control time the signal from the sensor is not restored, the ECU will transfer the system to the standby mode. In this mode, when you sharply press the gas pedal to the stop, the speed will increase slowly. By car, it will be possible to continue driving to the place of repair on its own. A slight increase in fuel consumption and a change in some other technical indicators of the engine are possible.

In the event that both sensors fail, the ECU will transfer the engine management system to emergency operation. The engine will only run at a speed just above idle (1500 min-1). At the same time, the car retains the ability to move independently, albeit at a slow speed. This will allow, if necessary, to leave the intersection, pull over to the side of the road or move the car to a safe place for a short distance.

In the engine management system, to switch to some operating modes, it is required to monitor the position of the brake pedal. The brake pedal switch is used as a brake pedal position sensor, in which there are two pairs of contacts.

The switch is connected to the computer with an additional wire. You will also need a sensor that monitors the engagement and disengagement of the clutch. It is installed in the clutch pedal bracket.

Clutch position sensor (for vehicles with manual gearbox) works on the same principle as the brake light switch.

The oxygen concentration sensor provides an output signal from which the ECU determines the oxygen concentration in the exhaust gases. Based on the data received, the ECU adjusts the amount of fuel injected into the engine cylinders, thereby maintaining the optimal proportion of the air-fuel mixture (this is necessary for the efficient operation of the catalytic converter). The sensitive element of the oxygen concentration sensor is located in the exhaust gas stream (before the catalytic converter). The operability of the sensor is possible only when its sensitive element is heated to a temperature of at least 300°C. To reduce the warm-up time, a heating element is built into the sensor.

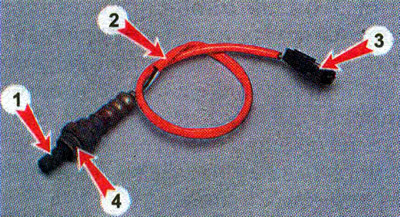

Oxygen concentration sensor: 1 - holes in the sensor housing for supplying exhaust gases to the sensing element; 2 - sensor wiring harness; 3 - connecting block; 4 - metal sealing ring of the sensor

In order for the engine to meet the stringent requirements of toxicity standards, a second oxygen concentration sensor is integrated into the exhaust gas system after the converter.

Warning! The presence of lead and silicon compounds in the exhaust gases can lead to failure of the oxygen concentration sensor. Therefore, the use of leaded gasoline is not allowed. When repairing the engine, do not use a sealant with a high content of silicone (silicon compounds), whose vapors can get through the crankcase ventilation system into the cylinders and further into the exhaust tract. Use a sealant that says on the packaging that it is safe for the oxygen sensor.

To reduce the emission of gasoline vapors from the fuel tank, the engine power supply system is equipped with a fuel vapor recovery system (see more details. «Supply system»). One of the elements of this system is the adsorber purge valve. Its operation is controlled by the engine ECU. The adsorber purge valve is located in the engine compartment on the right.

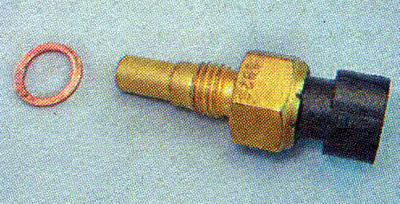

coolant temperature sensor (DTOZH) - a semiconductor device thermistor, the electrical resistance of which changes with changes in ambient temperature. DTOZH is installed in the thermostat housing. Based on the resistance of the sensor, the ECU evaluates the thermal regime of the engine. The data obtained are used in the calculation of most control commands for the elements of the engine control system, as well as for turning on the electric fan of the engine cooling system. In the event of a malfunction of the DTOZH, the electronic control unit switches the system to a backup mode of operation.

Coolant temperature sensor with copper o-ring

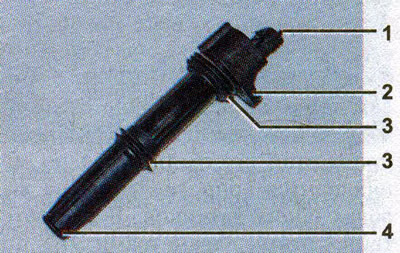

The engine uses four ignition coils. They are mounted directly on the spark plugs. This eliminates the reduction in spark power due to current leakage (this is possible if the insulation of high-voltage wires is damaged).

Ignition coil: 1 - conclusions for connecting the block of the wiring harness; 2 - eye for attaching the coil; 3 - sealing rings; 4 - tip for connecting to a spark plug

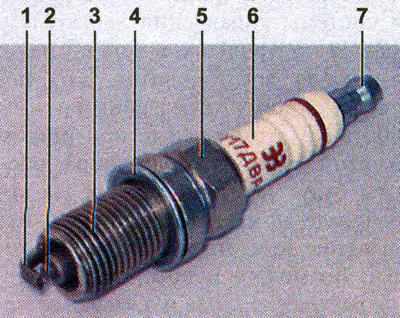

AU17DVRM spark plugs are used on engines, where:

- A - thread M 14x1.25;

- U - hexagonal part of the body on a 16 mm turnkey basis;

- 17 - glow number;

- D - length of the threaded part 19 mm, with a flat seating surface;

- B - protrusion of the thermal cone of the insulator beyond the end face of the threaded part of the housing;

Spark plug: 1 - side electrode; 2 - central electrode (in the thermal cone of the insulator); 3 - threaded part of the body; 4 - sealing ring; 5 - hexagonal part of the turnkey housing; 6 - insulator (It has a spark plug label on it); 7 - contact tip (removable, threaded)

- R - built-in resistor;

- M - bimetallic central electrode.

Candles from various manufacturers can be installed on the engine; similar type (see table. 9.2.1).

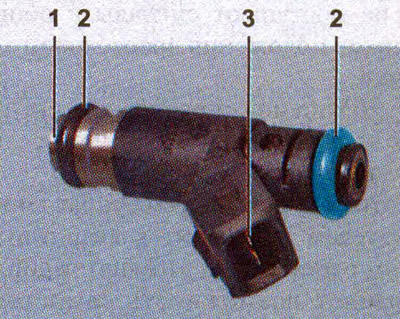

The nozzle is an electromagnetic needle valve, on the outlet pipe of which a sprayer with four calibrated holes is made. The injector opens on a signal from the ECU, while pressurized fuel is injected directly onto the intake valve. The amount of fuel entering the cylinder is controlled by the opening time of the injector. The engine has one injector for each cylinder.

Engine nozzle: 1 - atomizer; 2 - sealing rubber ring; 3 - terminals for connecting the wiring harness

The canister purge valve is installed on the air filter housing (see more details. «Supply system»).

The diagnostic connector block is designed to connect an external diagnostic device (for example, DST-2M) to the engine management system. The block is installed on the left under the instrument panel.